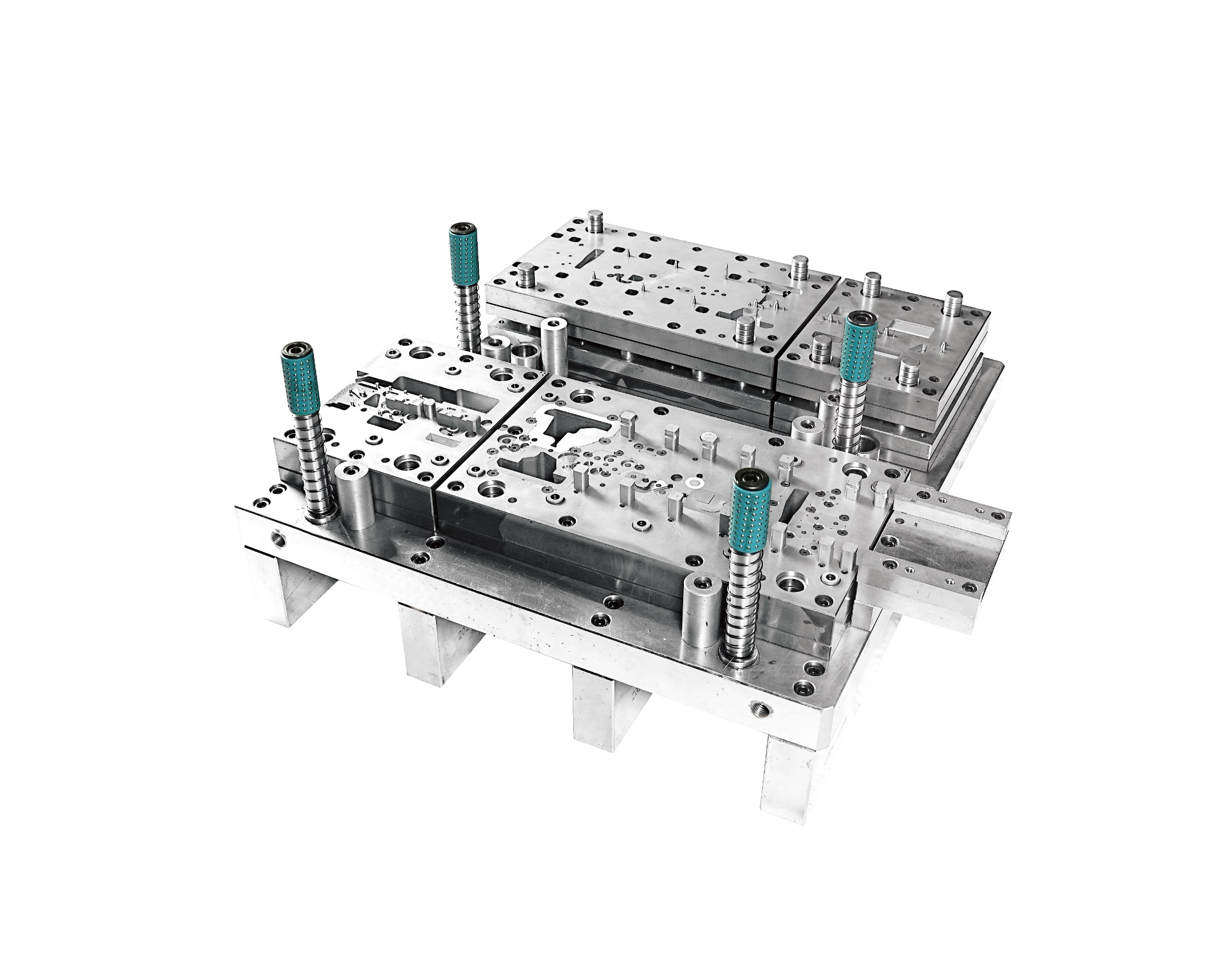

In today's rapidly developing manufacturing sector, progressive die technology, with its unique advantages, is becoming a key choice for many companies to improve production efficiency and ensure product quality, playing an indispensable role across various industries.

The greatest benefit of progressive die technology lies in its significant improvement in production efficiency. It enables multiple stamping processes to be completed on a single piece of equipment, from material feeding, stamping, to finished product output, all in a continuous and uninterrupted process. Compared to traditional single-step dies, it eliminates the time required for multiple clamping and positioning, significantly shortening production cycles. For example, in the mass production of small hardware parts, the use of progressive die technology can achieve dozens or even hundreds of stamping cycles per minute, increasing production efficiency by several times, effectively meeting market demand for high-volume production.

Ensuring consistent and stable product quality is also a significant advantage of progressive die technology. Since all processes are completed within the same die, positioning errors caused by multiple clamping are avoided, effectively ensuring product dimensional and shape accuracy. Every product follows the same production process and standards, reducing defective products and improving product qualification rates, earning the company a positive market reputation. From a cost perspective, continuous die production can reduce production costs for companies. On the one hand, continuous production reduces the number of machines used, lowering equipment investment and maintenance costs. On the other hand, it reduces manual operations, lowering labor costs and minimizing losses due to human error. Over the long term, this can save companies significant capital and improve their economic returns.

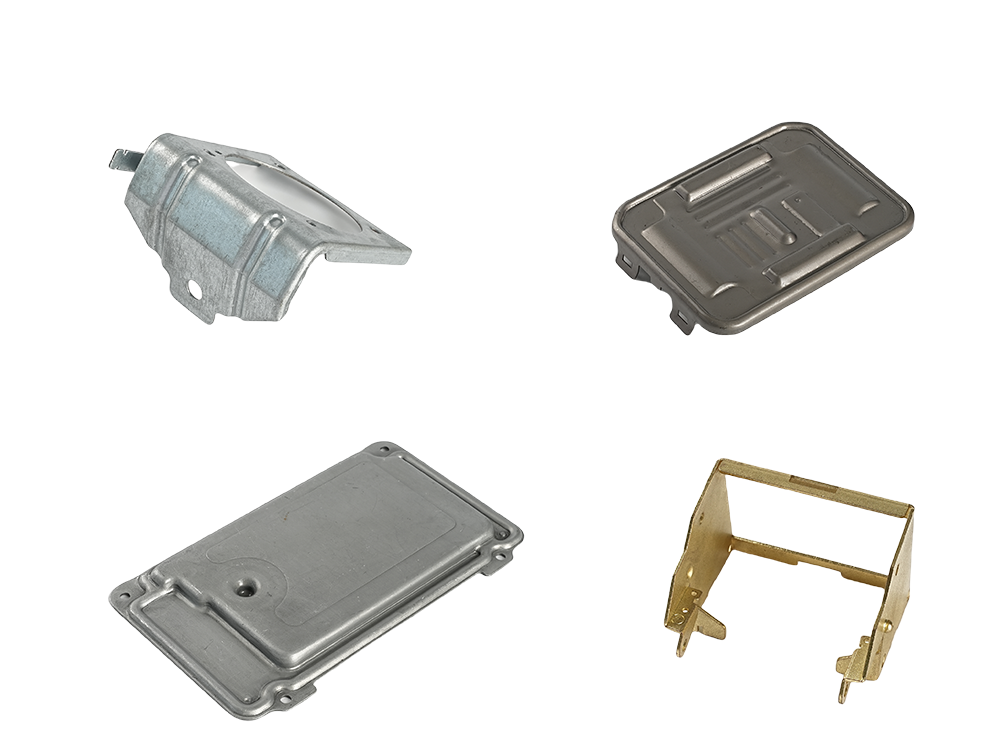

Continuous die production has a wide range of applications. In the automotive industry, it is used to produce automotive parts such as door hinges, seat rails, and engine gaskets. These parts require high precision and strength, and continuous die production can accurately perform complex stamping processes to meet the stringent standards of automotive manufacturing.

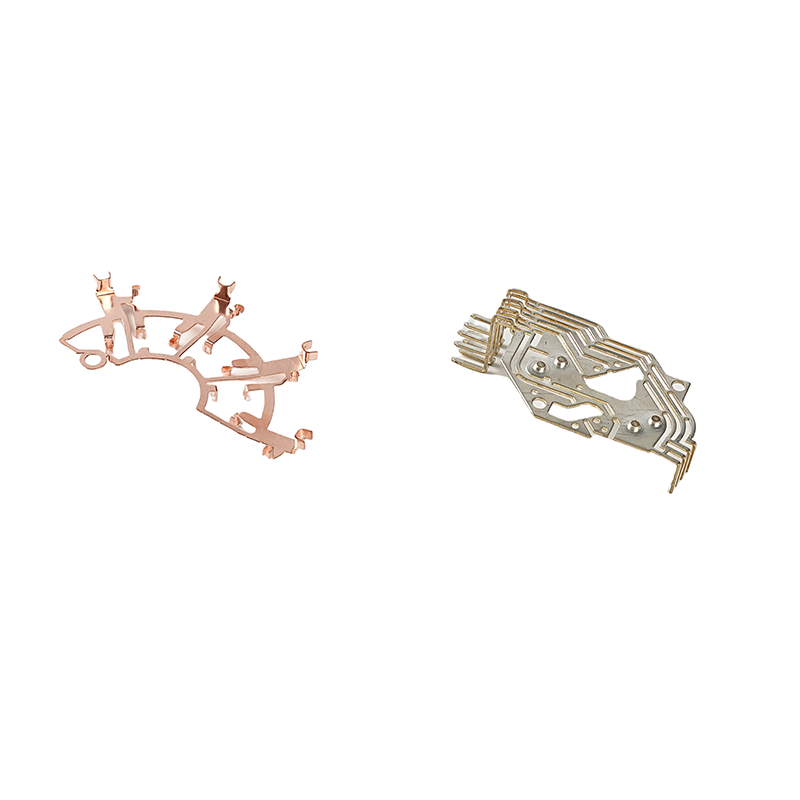

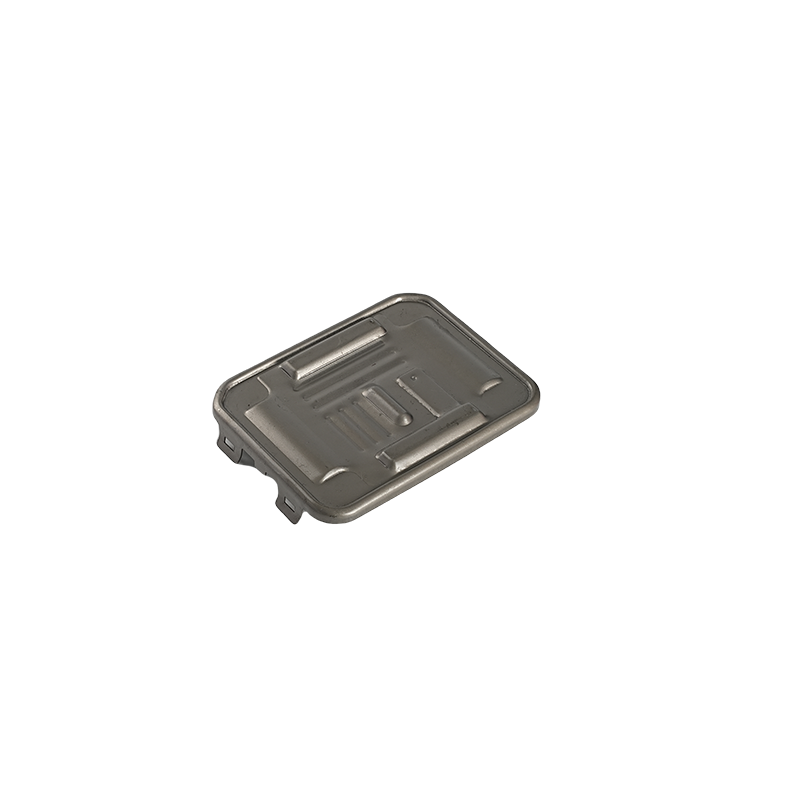

Continuous die production also plays a vital role in the electronics and electrical industry. Small, precision components such as precision connectors, shielding covers, and heat sinks used in electronic products like mobile phones and computers rely on continuous die production for efficient and precise production. It ensures the dimensional accuracy and consistency of these small parts, ensuring the proper assembly and operation of electronic products. Furthermore, in the hardware industry, progressive die production is used to produce a variety of standard and custom-shaped parts, such as bolts, nuts, washers, and various stamped parts, providing strong support for the large-scale production of hardware products.

With the continuous development of the manufacturing industry, progressive die technology is also advancing. Its advantages in improving production efficiency, ensuring product quality, and reducing costs will become more prominent, contributing further to the high-quality development of modern manufacturing.