Precision molds have extensive and important applications in many fields. The following are some of the main aspects:

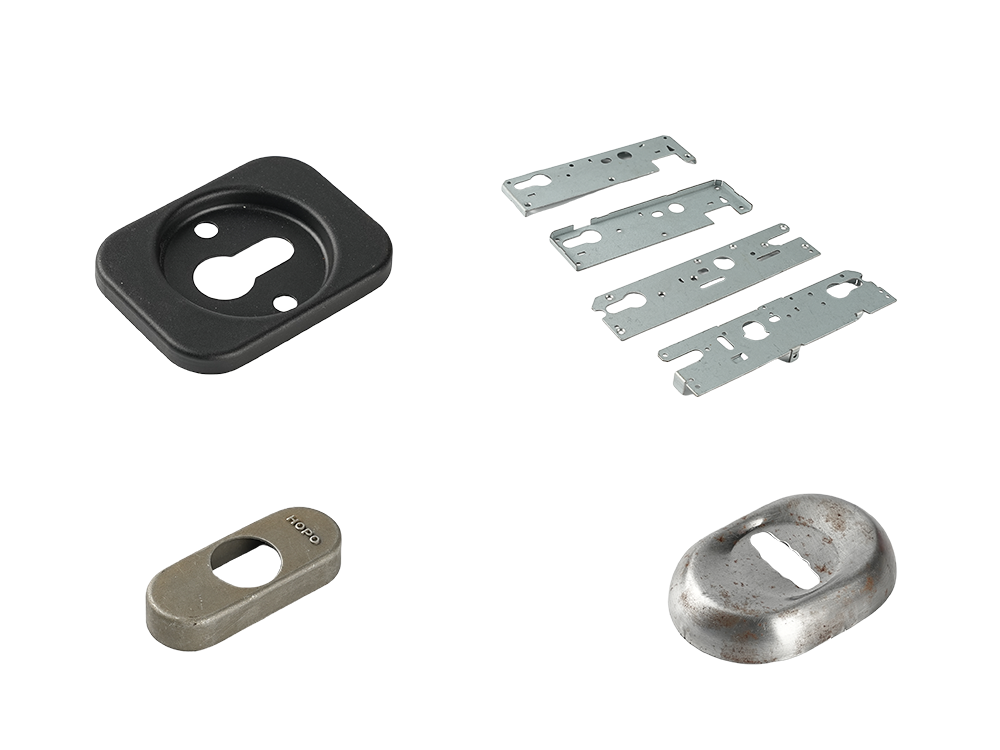

Automobile manufacturing

Engine parts: such as cylinder blocks, cylinder heads, crankshafts, etc. The production of these parts requires high-precision molds to ensure dimensional accuracy and surface quality to ensure the performance and reliability of the engine.

Body structure parts: Large covering parts such as car doors, hoods, trunk lids, and structural parts such as frames are all stamped and formed by precision molds, which can achieve complex shapes and good surface quality while ensuring the consistency and interchangeability of parts.

Interior parts: The dashboard, seat frame, air-conditioning vents, etc. of the car interior can be manufactured using precision molds to achieve high-precision assembly and beautiful appearance design, improving the comfort and quality of the car.

Electronic information

Mobile phones and tablets: Mobile phone shells, buttons, tablet shells and internal structural parts are usually produced using precision injection molds. These molds can produce ultra-thin, high-precision plastic parts to meet the requirements of electronic products for exquisite appearance and compact structure.

Chip packaging: In the chip manufacturing process, precision molds are used to manufacture packaging shells to protect chips from the external environment. High-precision molds ensure the dimensional accuracy and reliability of the package, which is crucial to the performance and stability of the chip.

Connectors: The shells and internal contacts of various electronic connectors require precision molds to ensure their dimensional accuracy and contact performance, and ensure that the electrical connection between electronic devices is stable and reliable.

Home appliance field

White appliances: The shells and internal parts of refrigerators, washing machines, air conditioners, etc., such as the inner tank of refrigerators, the barrel of washing machines, the shell and impeller of air conditioners, etc., can be mass-produced through precision mold manufacturing, while ensuring the quality and appearance consistency of the products.

Small appliances: Such as hair dryers, vacuum cleaners, electric kettles, etc., their shells and some key components also rely on precision molds to produce to meet consumers' needs for beautiful appearance, comfortable use and stable performance of small appliances.

Medical devices

Medical syringes: The barrel, piston, needle seat and other parts of the syringe require precision molds to ensure their dimensional accuracy and surface quality to ensure the sealing, accuracy and safety of the syringe.

Dentures: Dentures made by precision molds can accurately match the patient's oral structure and have good comfort and aesthetics.

Medical equipment shell: The shell of equipment such as ultrasonic diagnostic equipment and medical monitors can be produced using precision molds to achieve good heat dissipation performance, electromagnetic shielding effect and beautiful appearance design, while ensuring the stability and reliability of the equipment.

Aerospace

Engine parts: Key parts such as blades and combustion chambers of aircraft engines need to be cast or forged using precision molds to ensure high precision and high performance of the parts to meet the working requirements of aircraft engines under extreme conditions such as high temperature and high pressure.

Aircraft structural parts: Structural parts such as wings and fuselage frames of aircraft can be lightweight through precision mold manufacturing, while ensuring the strength and reliability of the structure, and improving the fuel efficiency and flight performance of the aircraft.