Description

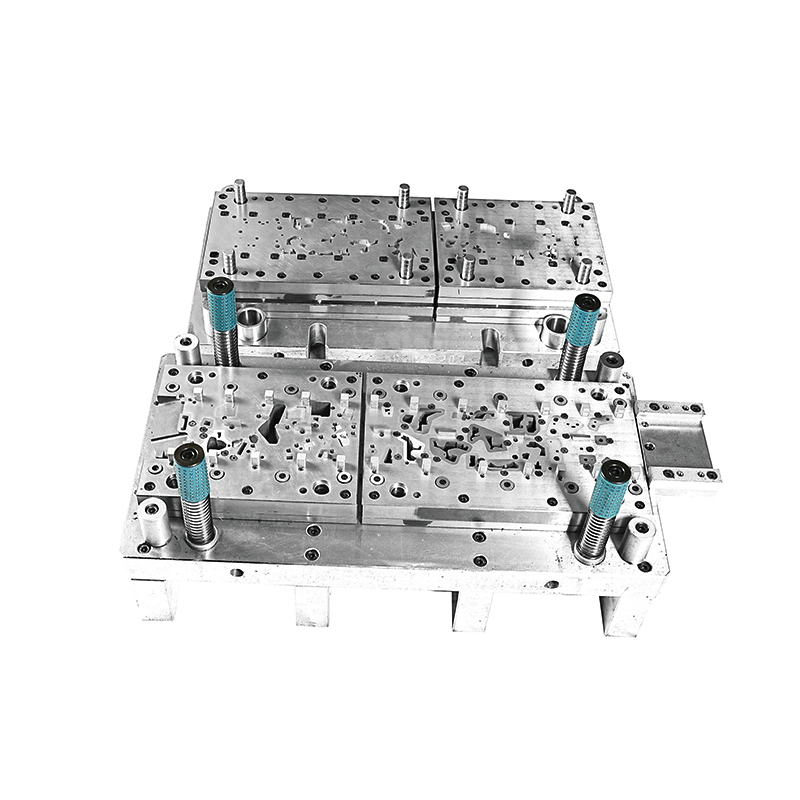

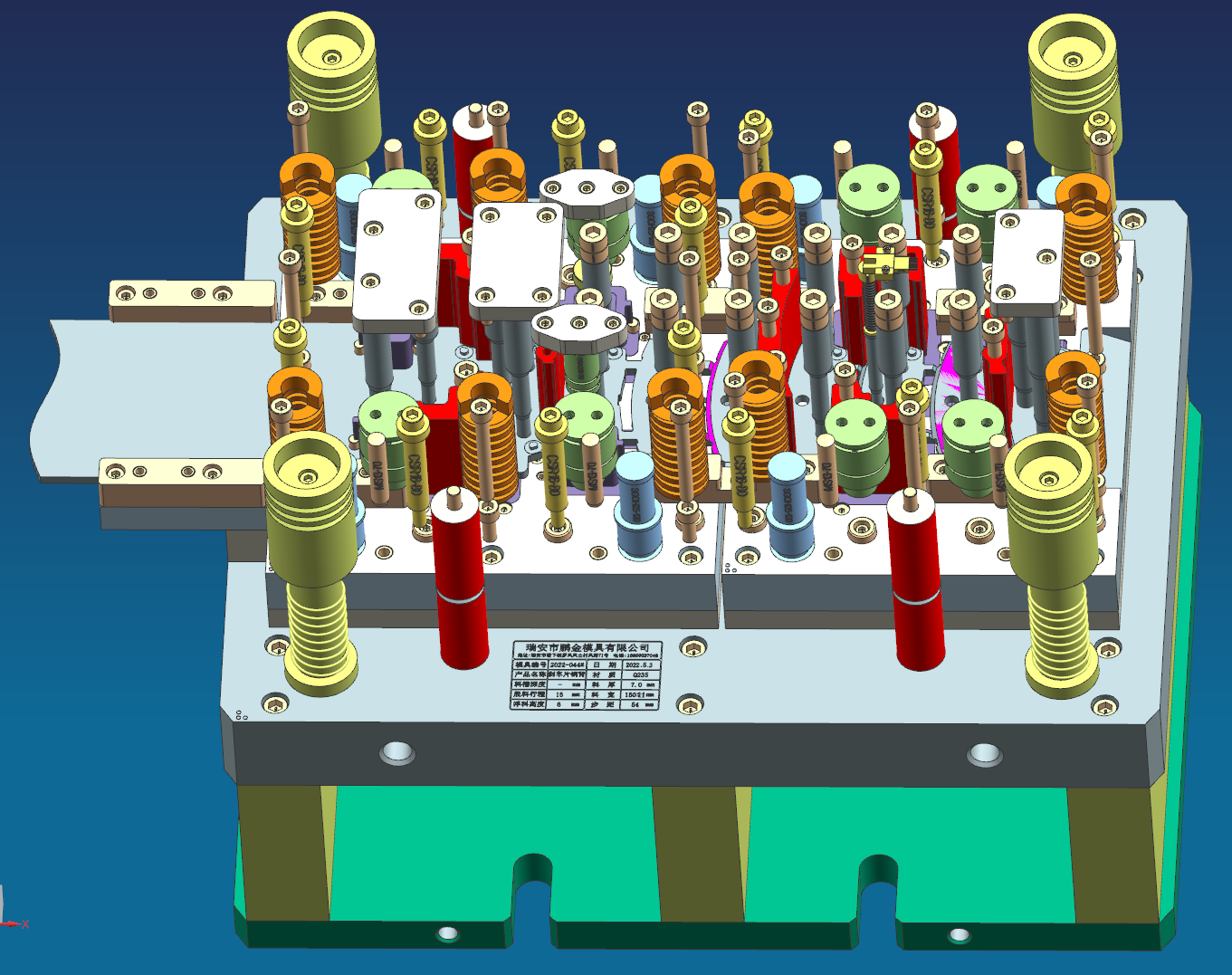

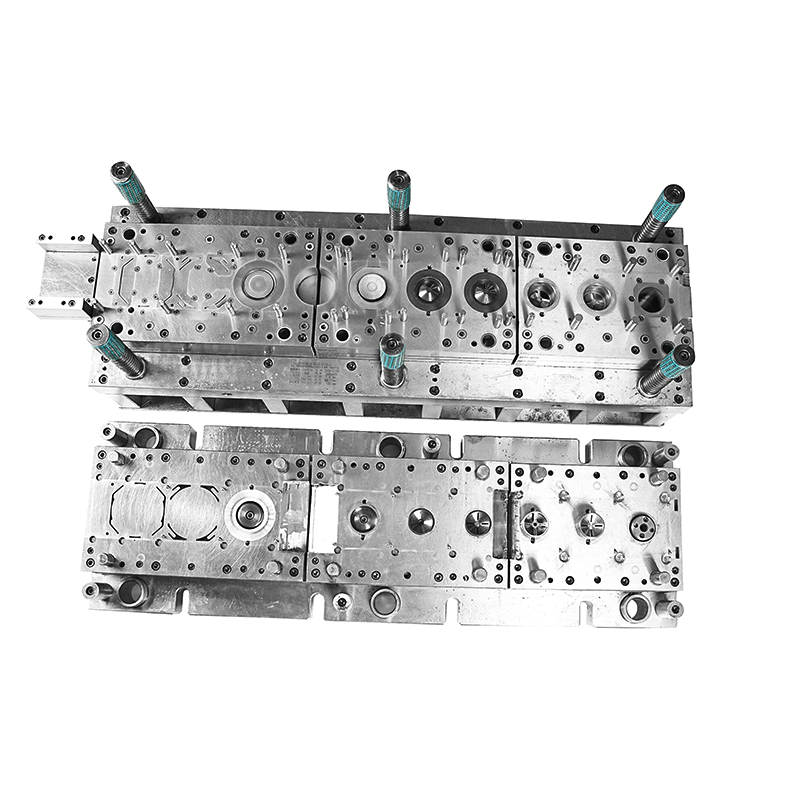

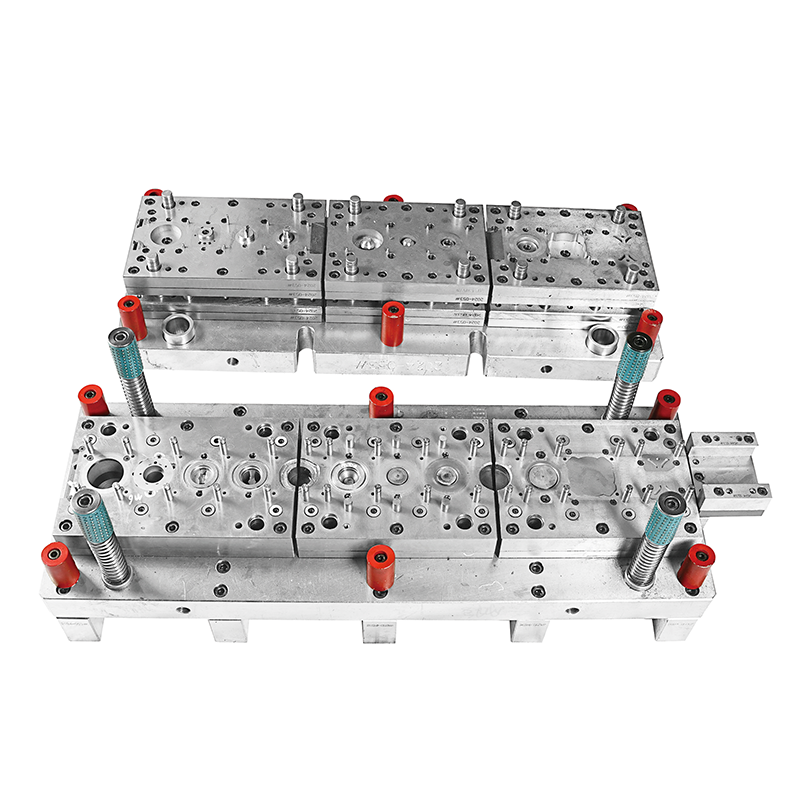

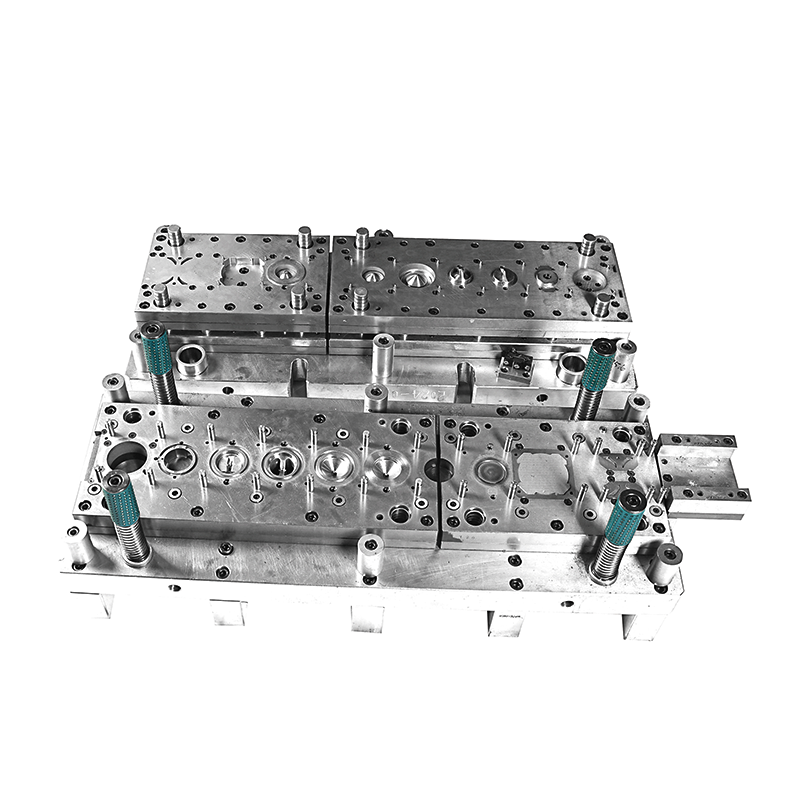

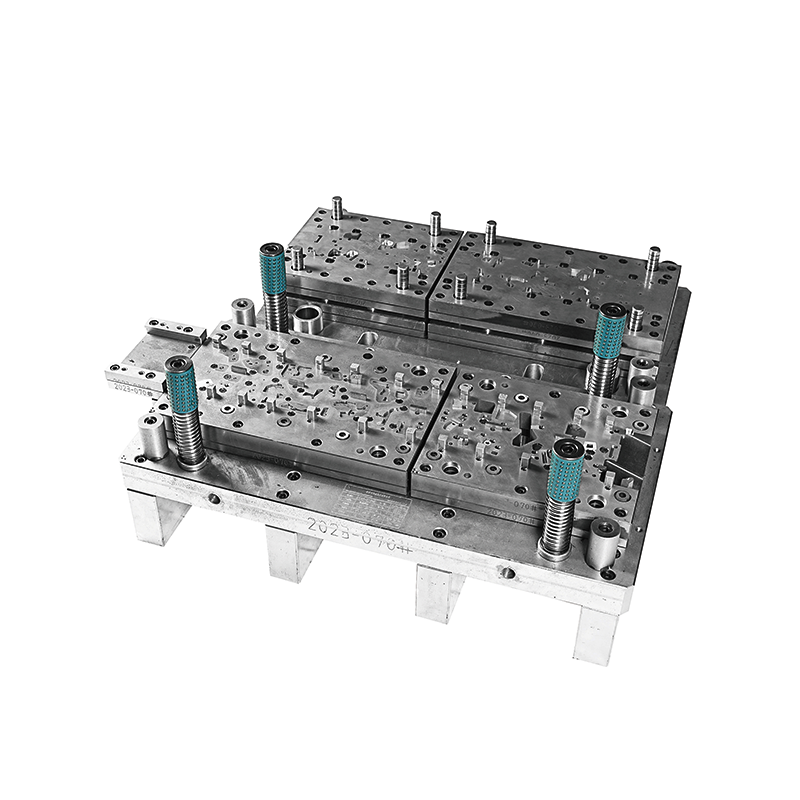

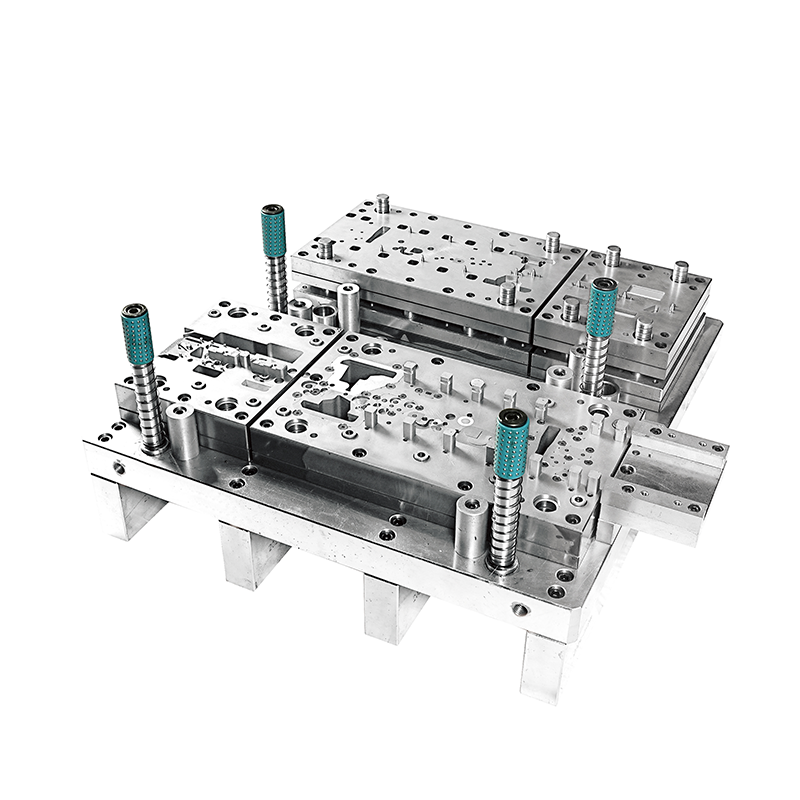

The continuous stamping die for decorative parts is a die used to produce decorative parts. It processes metal sheets into parts with specific shapes and decorative effects by continuous stamping.

Mold structure: generally composed of upper die, lower die, guide device, positioning device, unloading device and feeding device. The upper die and lower die are the core parts of the die, which contain various punches and concave dies for stamping and are designed according to the shape and process requirements of the decorative parts. The guide device usually uses guide pins and guide sleeves to ensure the precise matching of the upper and lower dies during the stamping process. The positioning device is used to accurately determine the position of the sheet to ensure the accuracy of each stamping. The unloading device is responsible for unloading the workpiece from the die after the stamping is completed. The feeding device continuously feeds the metal sheet into the working area of the die at a certain step distance.

Mold features

High appearance requirements: Decorative parts usually focus on appearance quality, so the working surface of the mold requires high finish and precision to ensure that the surface of the stamped decorative parts is smooth and flawless, and the dimensional accuracy meets the design requirements.

Process diversity: In order to achieve different decorative effects, the mold may need to have a variety of stamping processes, such as stretching, embossing, knurling, etc., to meet the design requirements of different decorative parts.

High production efficiency: The continuous stamping method can realize automated production, greatly improve production efficiency, reduce labor costs, and is suitable for the production of large quantities of decorative parts.

Applications

Widely used in construction, home furnishing, automobile, electronics and other industries. In the construction field, it is used to produce door and window decorative strips, ceiling decorative panels, etc.; in the home furnishing industry, it can be used to make furniture handles, decorative frames, etc.; in the automobile industry, it is used to produce body decorative strips, interior decoration parts, etc.; in the electronics industry, it can be used to manufacture decorative parts for electronic product shells, etc.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.