Description

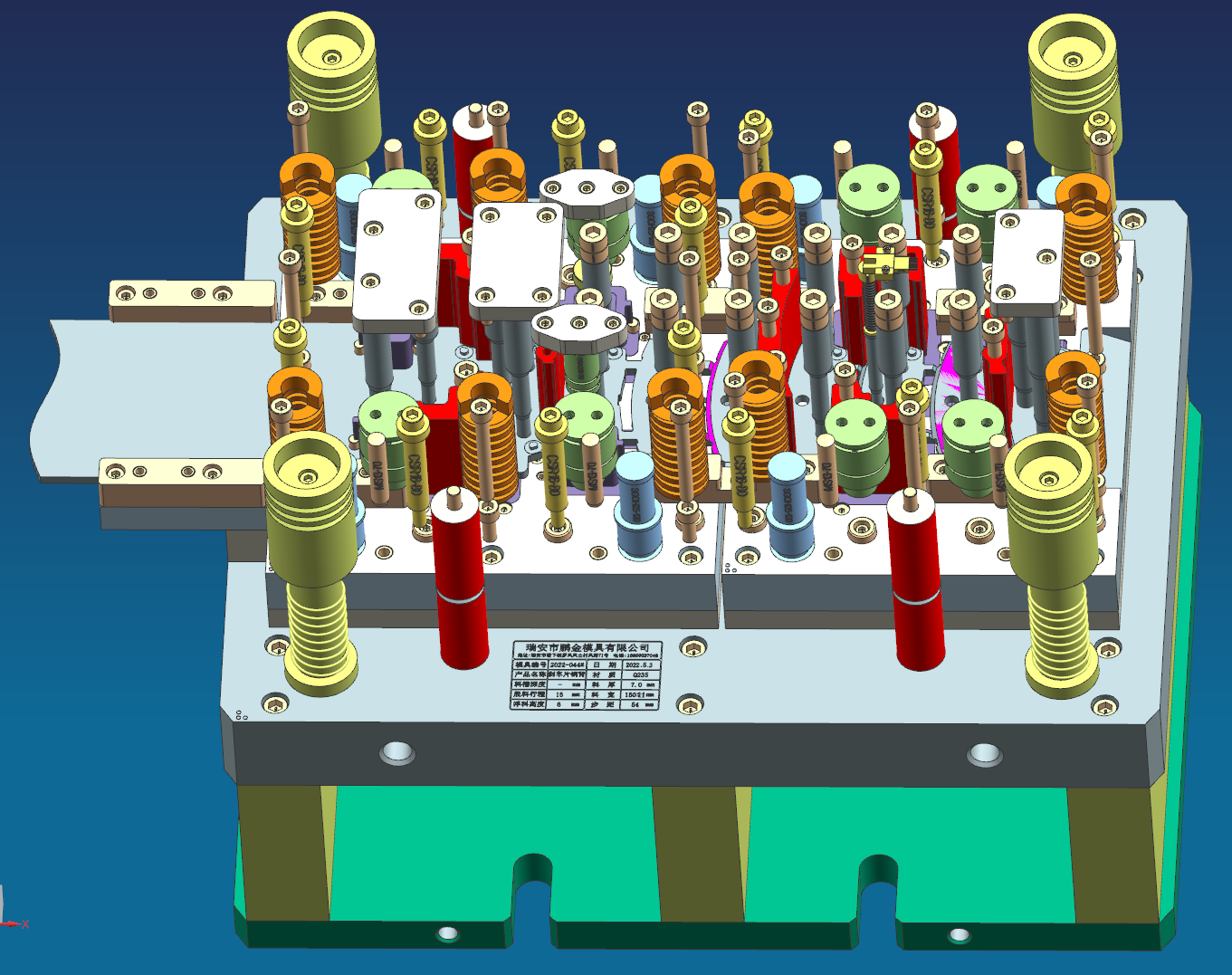

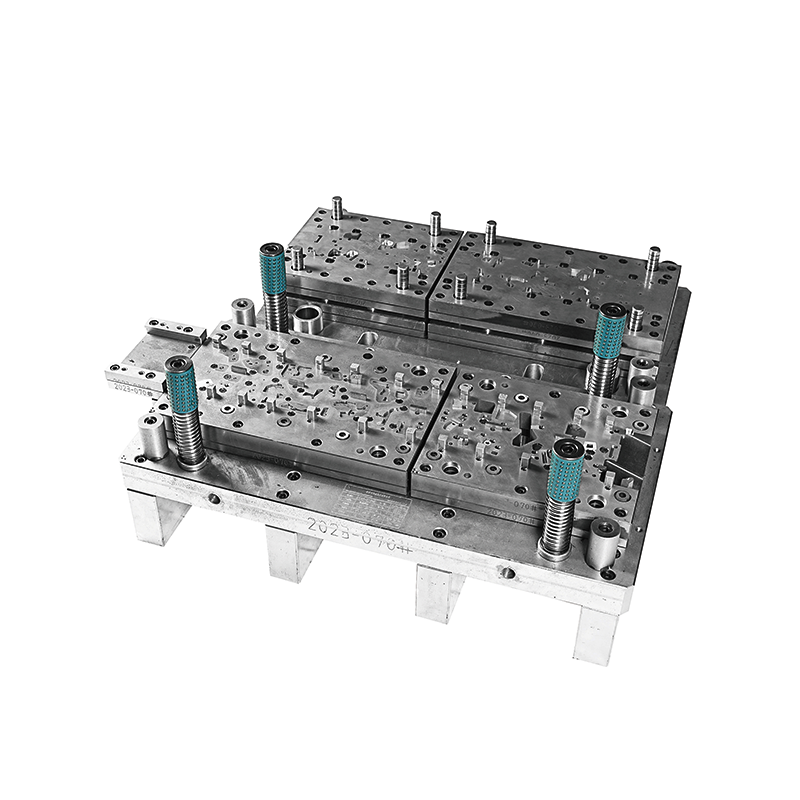

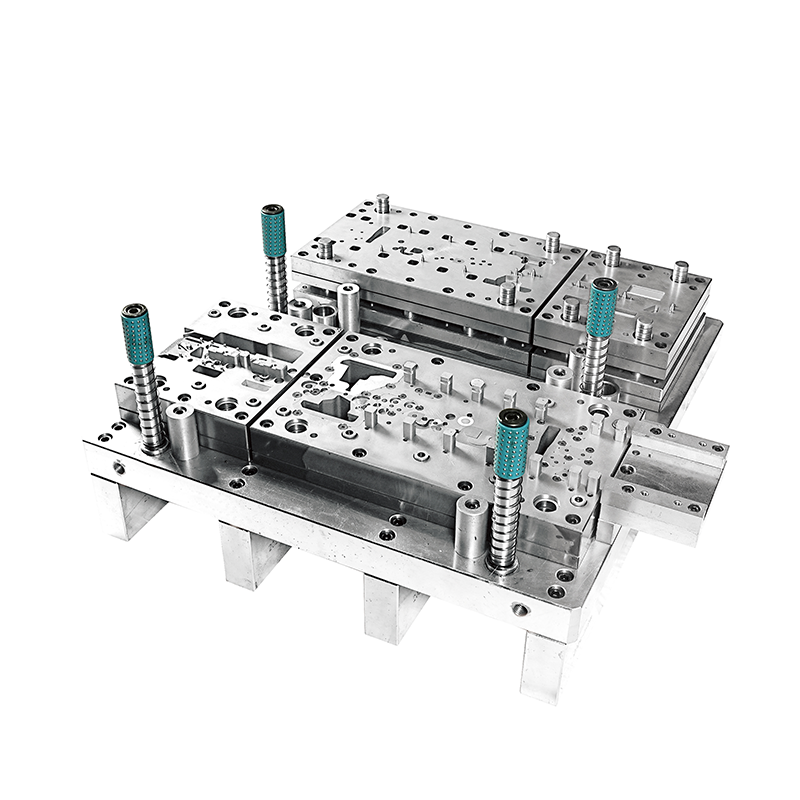

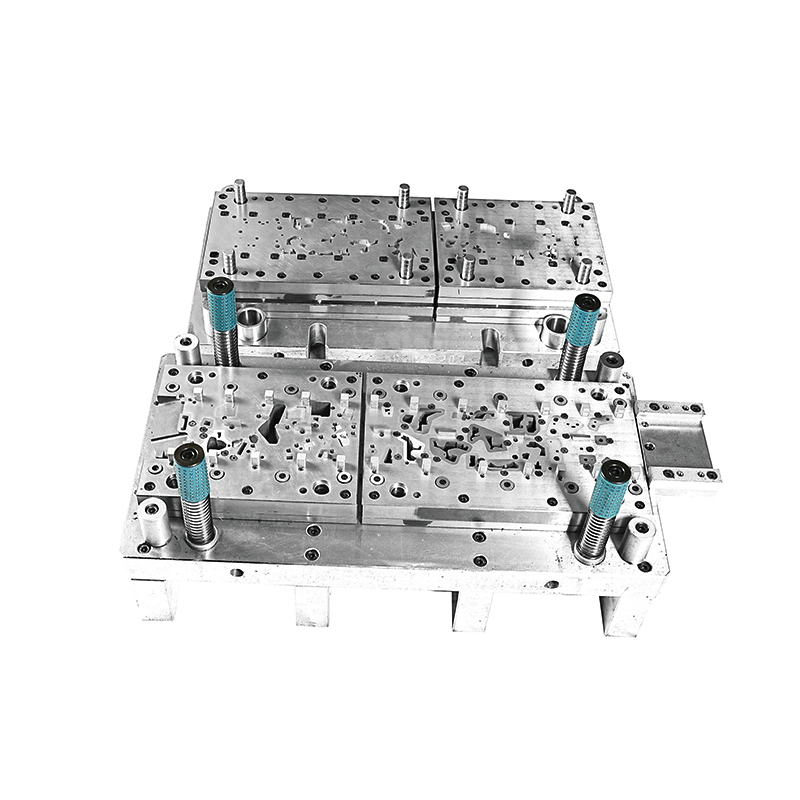

3D mold view design is a design process that uses 3D design software to present the structure, shape, size, etc. of the mold in an intuitive 3D model form.

The designer must first conceive according to the characteristics of the product and production requirements, and then accurately create 3D models of each component of the mold in the software, including the cavity, core, various sliders, ejection mechanism, etc., and assemble these components according to the actual assembly relationship to form a complete mold assembly. Through 3D mold view design, the internal structure and working principle of the mold can be clearly displayed, which is convenient for designers to check whether there is interference between the components, timely discover design defects and optimize them, and also provide an accurate model basis for subsequent mold manufacturing, assembly and product molding process simulation analysis.

Applications

Automobile manufacturing, electronic equipment manufacturing, home appliance manufacturing, aerospace field, medical machinery and equipment field, daily necessities field

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

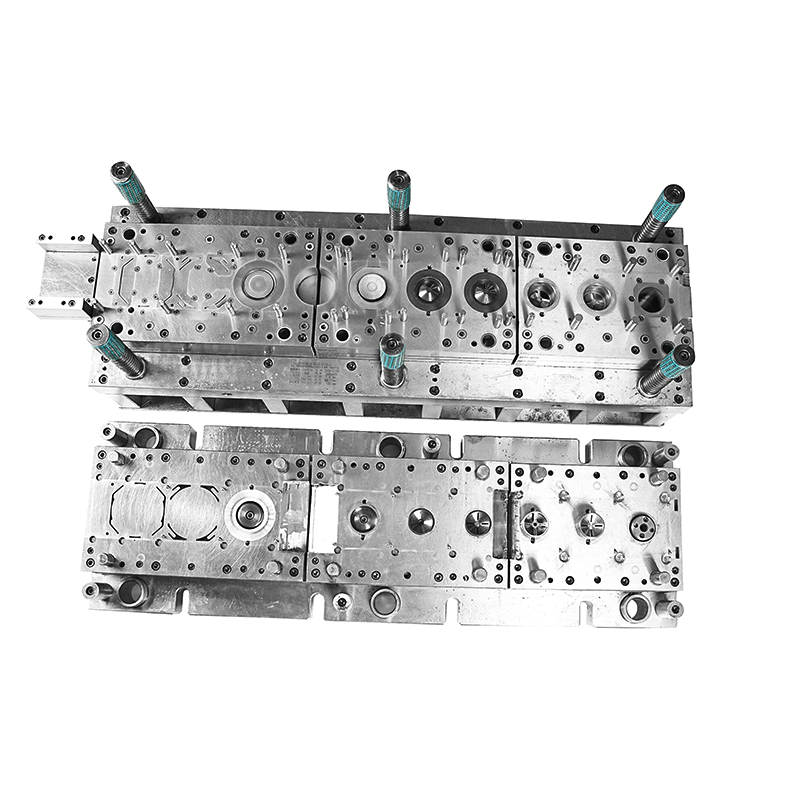

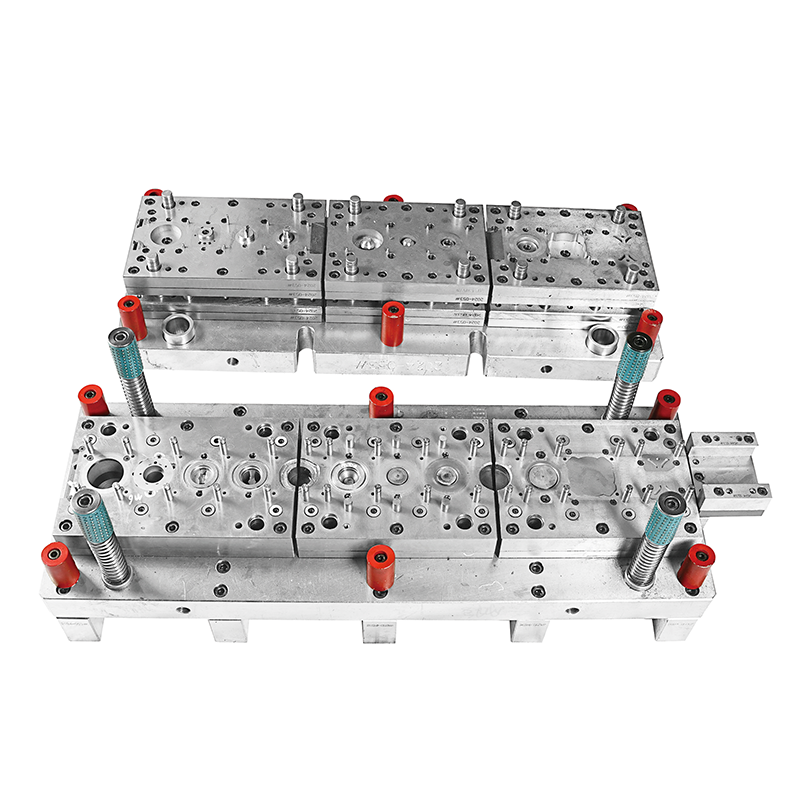

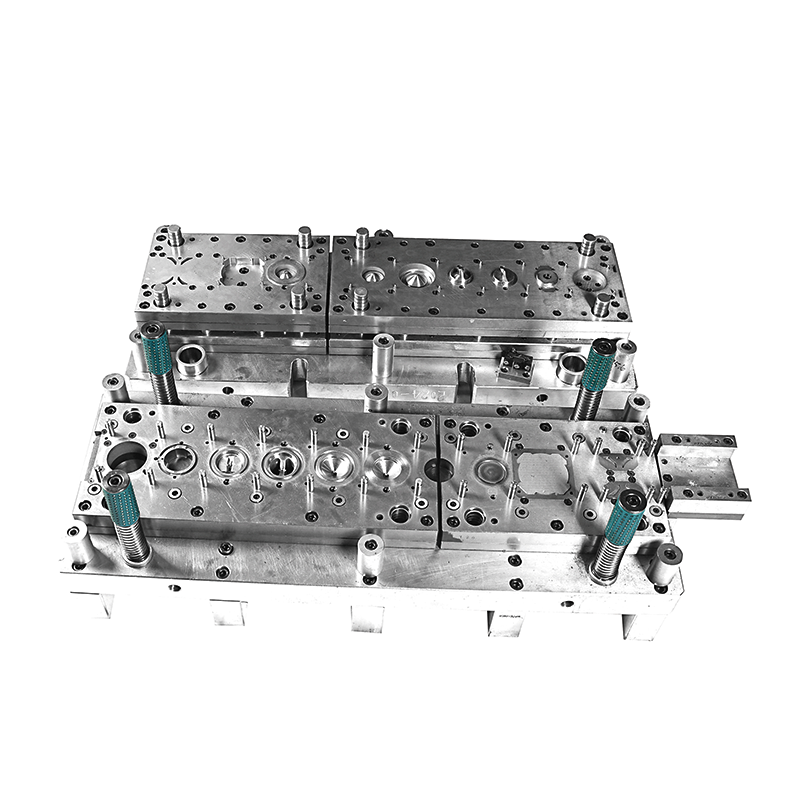

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.