Description

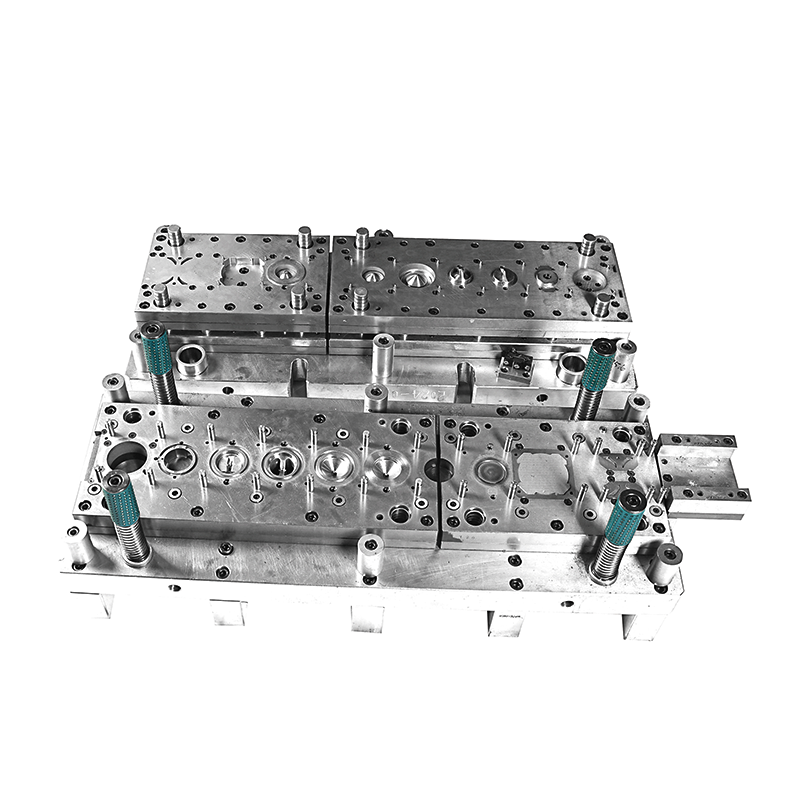

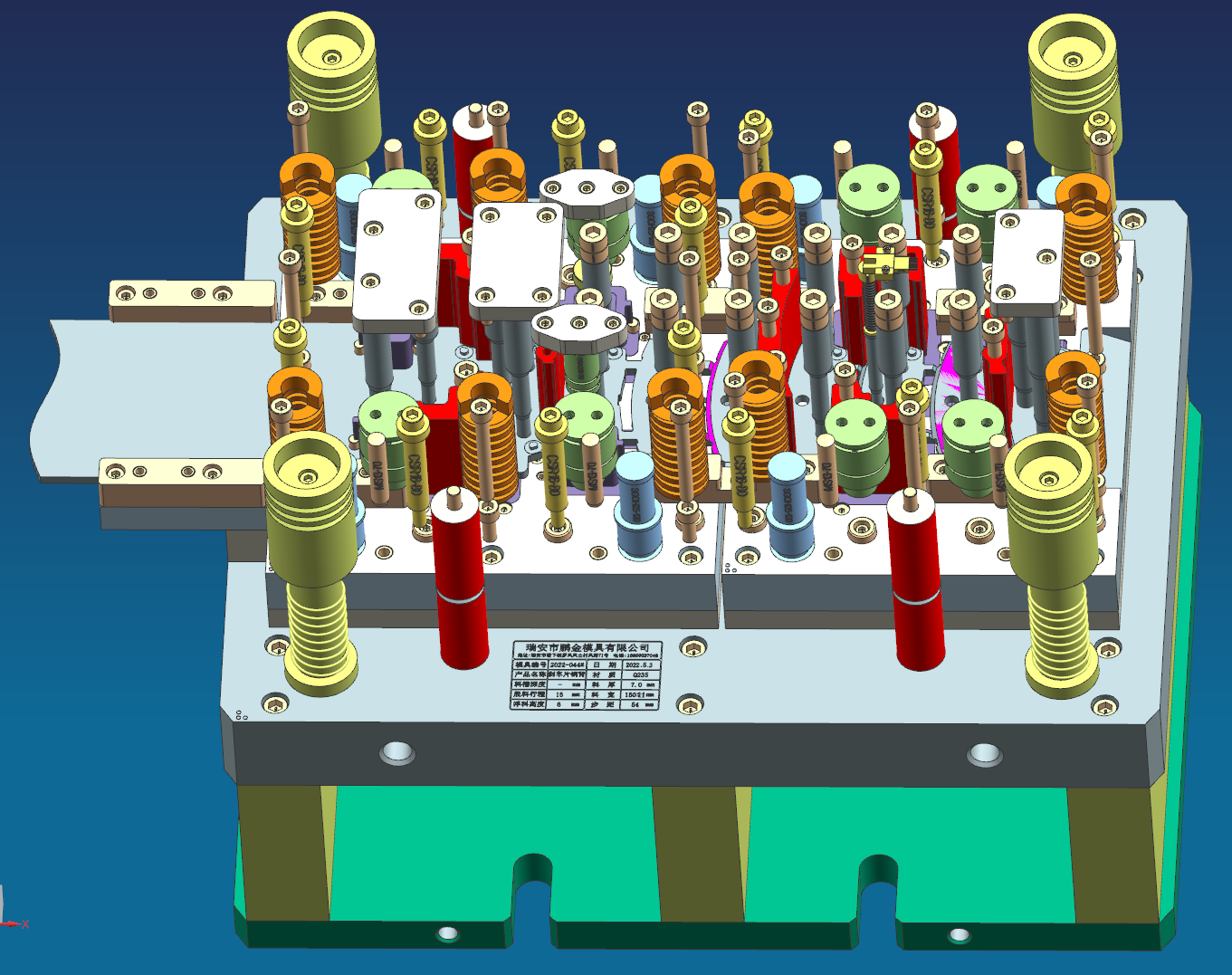

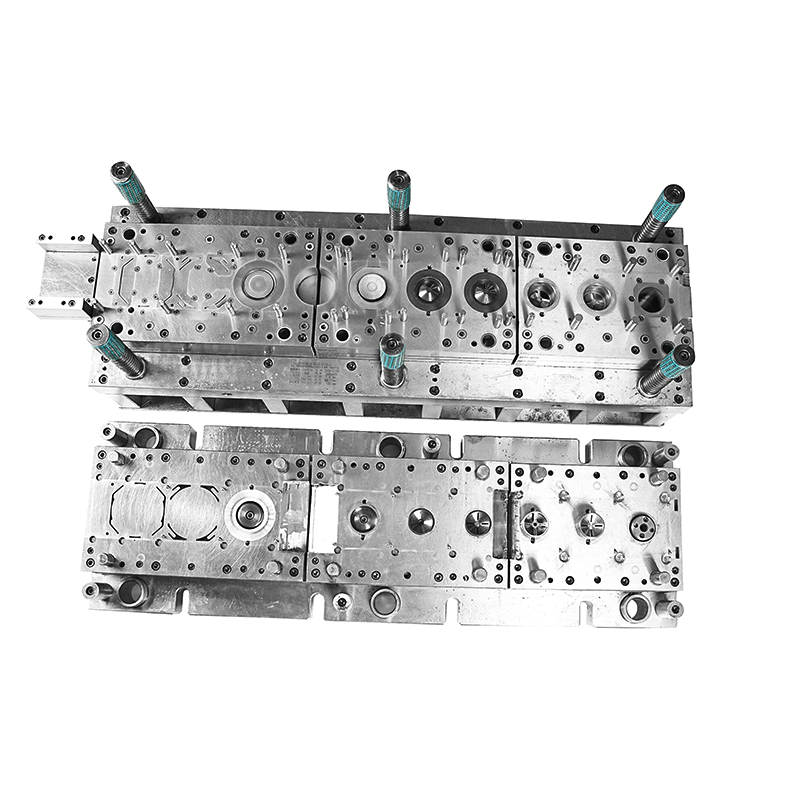

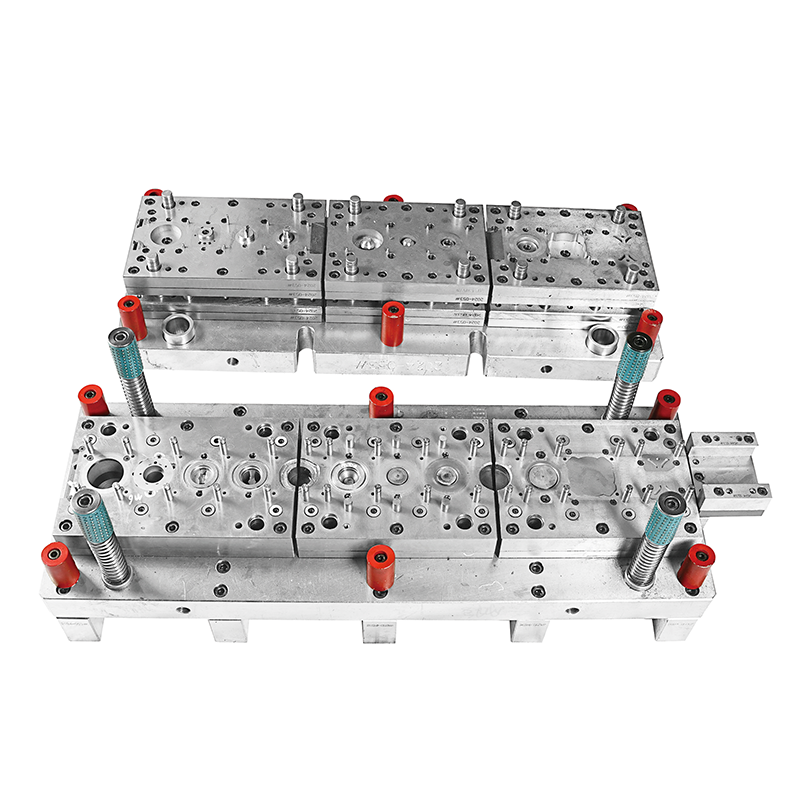

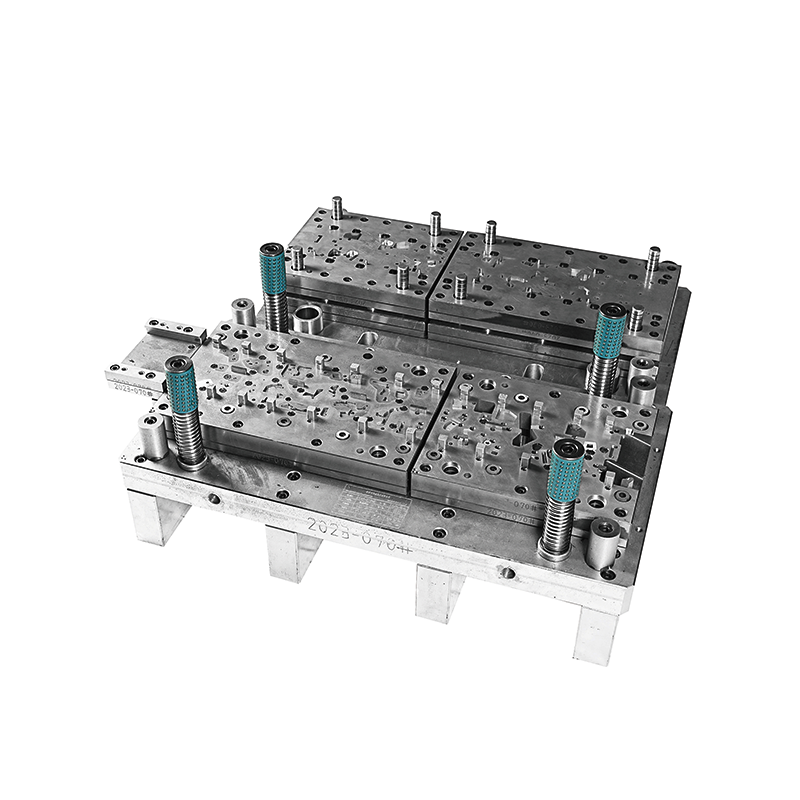

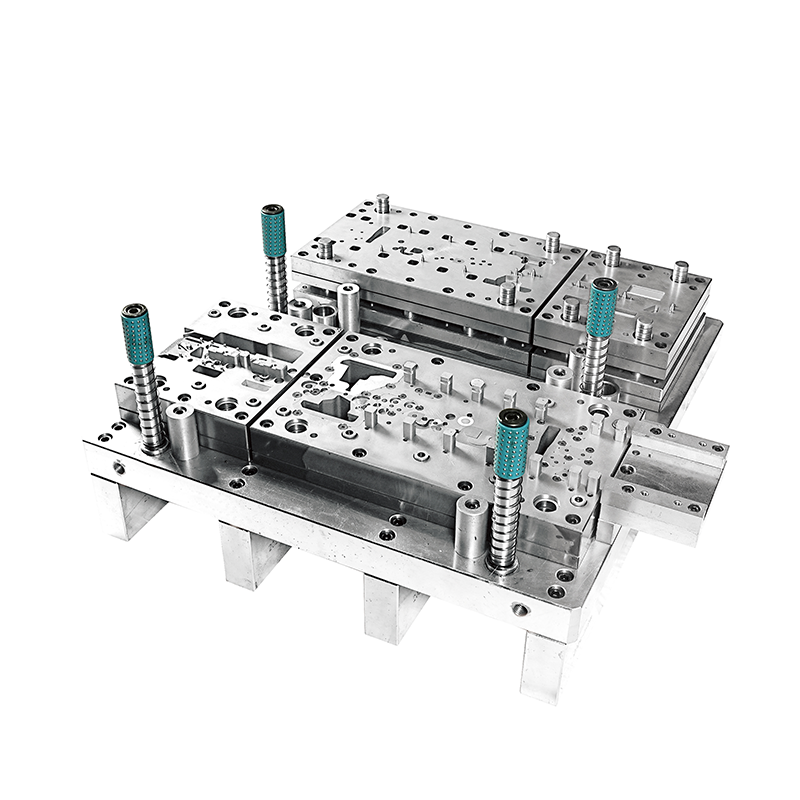

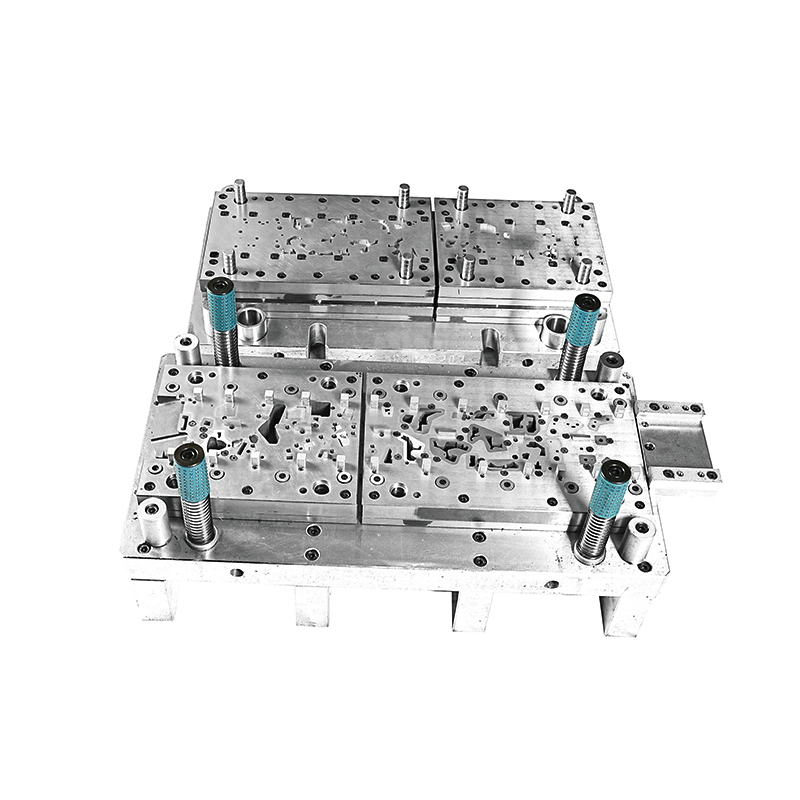

he stainless steel shell stretching and stamping die is a die specially used for processing stainless steel shells. It converts stainless steel sheets into shells with specific shapes and sizes through processes such as stretching and stamping.

Mold structure: It usually consists of an upper die part and a lower die part. The upper die includes components such as an upper die seat, a punch, and a stripper plate, while the lower die includes components such as a lower die seat, a concave die, and a pressure ring. In addition, there are guide mechanisms such as guide pins and guide sleeves to ensure the precise fit of the upper and lower dies during movement; the positioning device is used to accurately determine the initial position of the stainless steel sheet to ensure the accuracy of each stamping.

Mold features

High strength and wear resistance: Since stainless steel materials have high strength and hardness, the mold needs to have sufficient strength and wear resistance to withstand the huge pressure and friction during the stamping process to ensure the service life of the mold.

High precision: In order to ensure the dimensional accuracy and surface quality of the stainless steel shell, the manufacturing accuracy of the mold is required to be high, and precision machining technology is usually required to ensure that each component of the mold has accurate size and shape.

Good surface quality: The working surface of the mold needs to be finely polished and processed to prevent the stainless steel sheet from sticking to or scratching the mold surface during the stamping process, thereby ensuring the surface quality of the stainless steel shell.

Applications

Widely used in electronic equipment, home appliances, medical equipment and other industries. For example, the chassis shell of electronic equipment, the microwave oven liner of home appliances, the instrument shell of medical equipment, etc.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.