Description

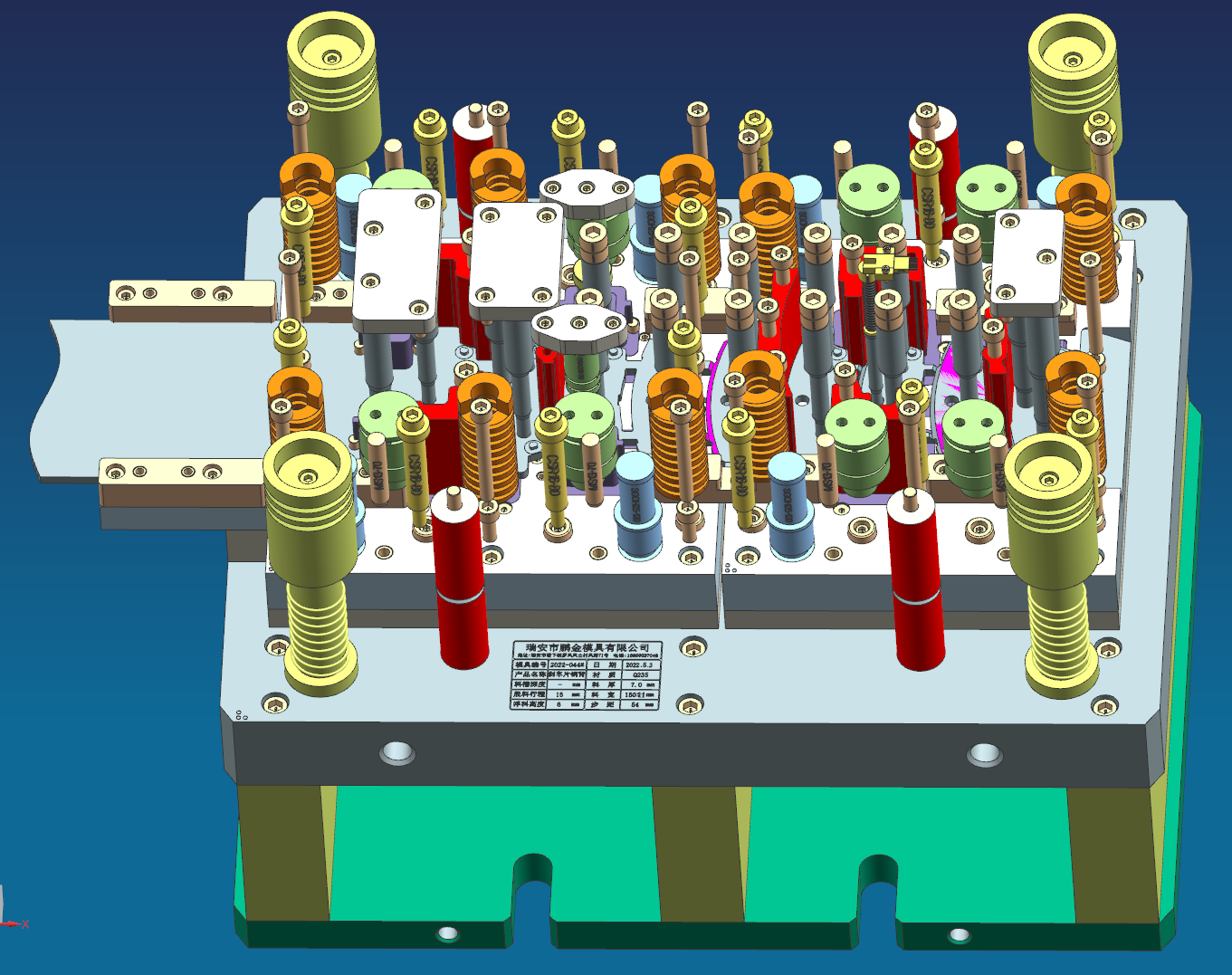

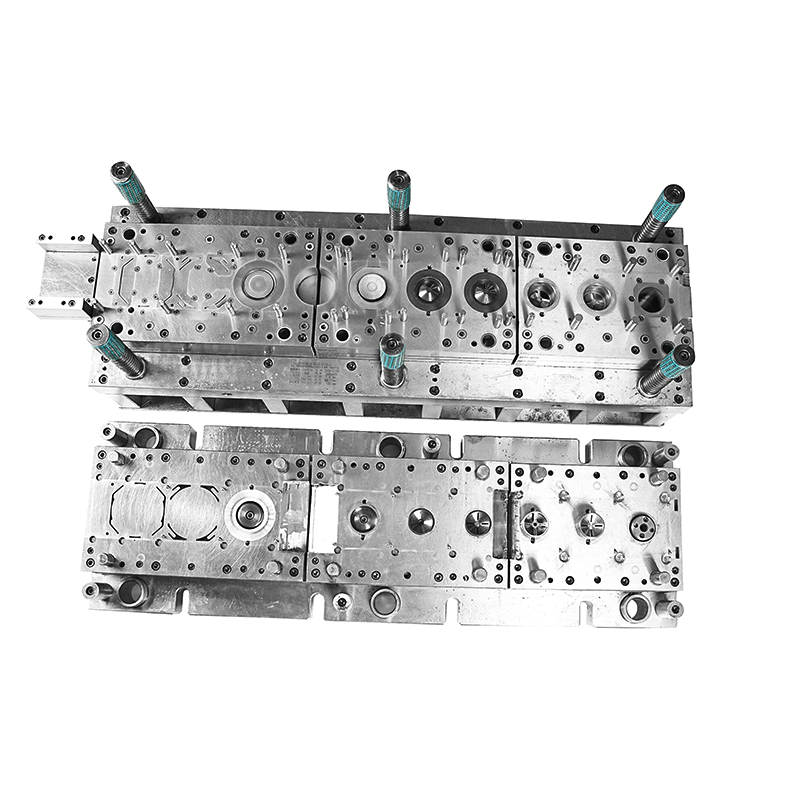

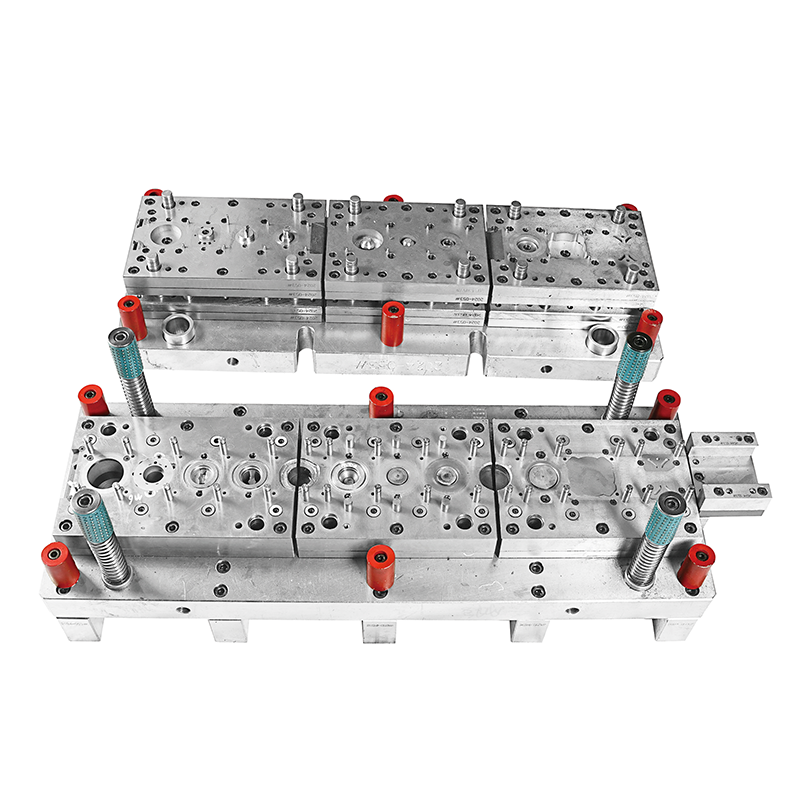

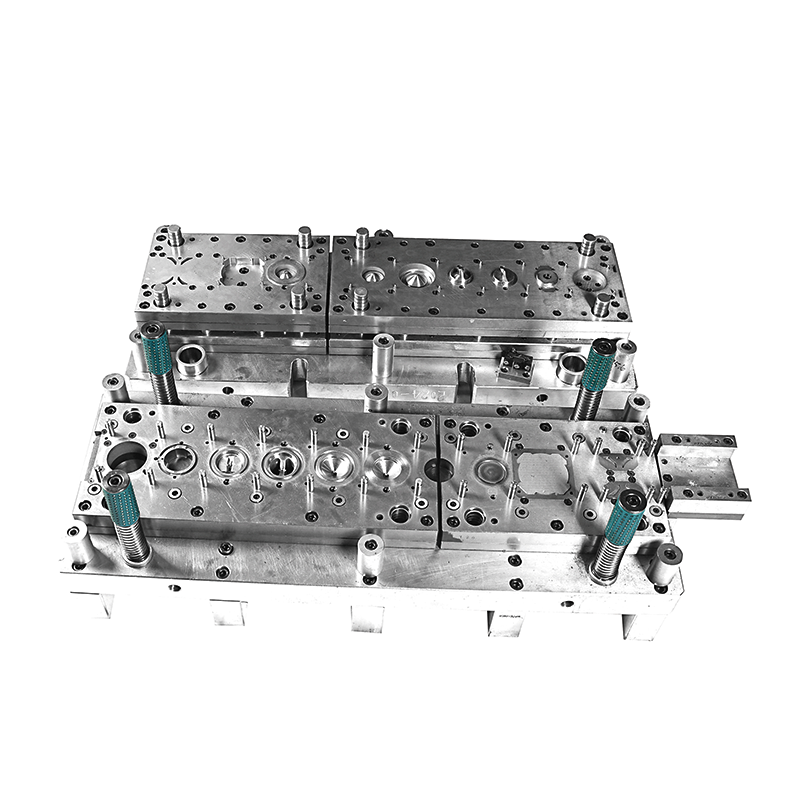

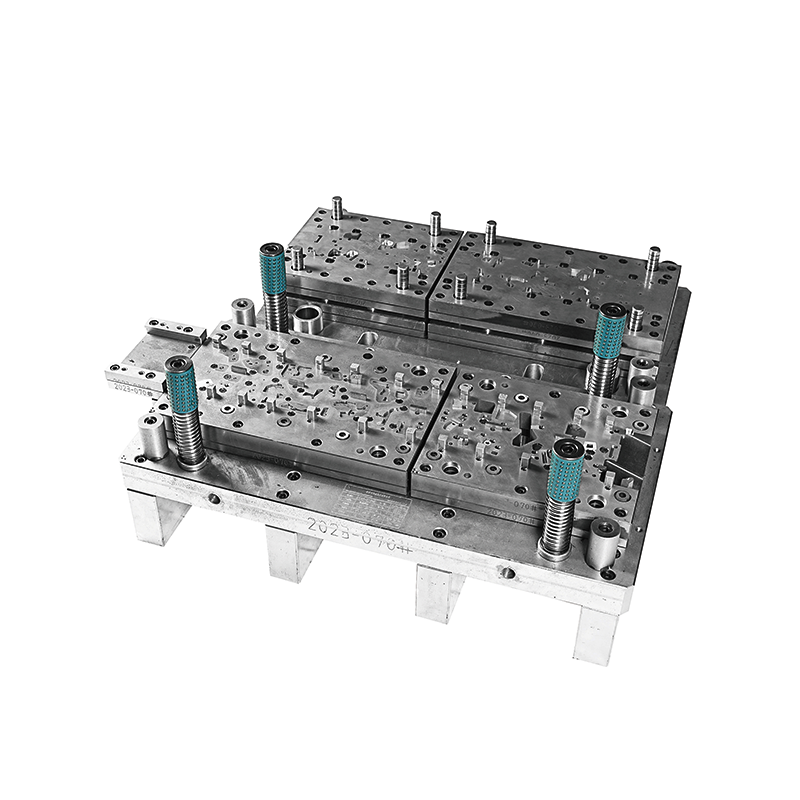

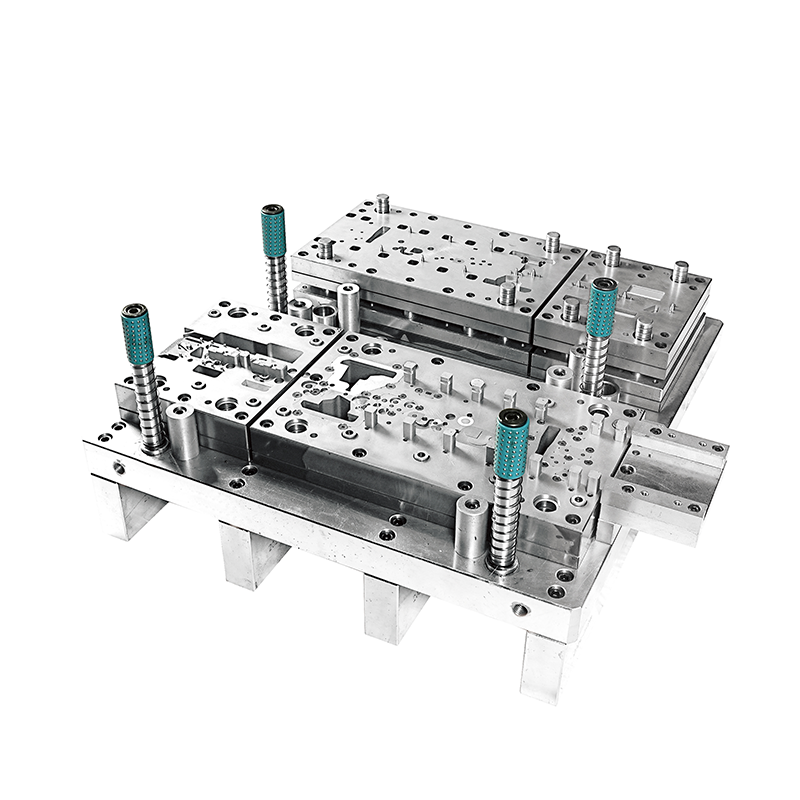

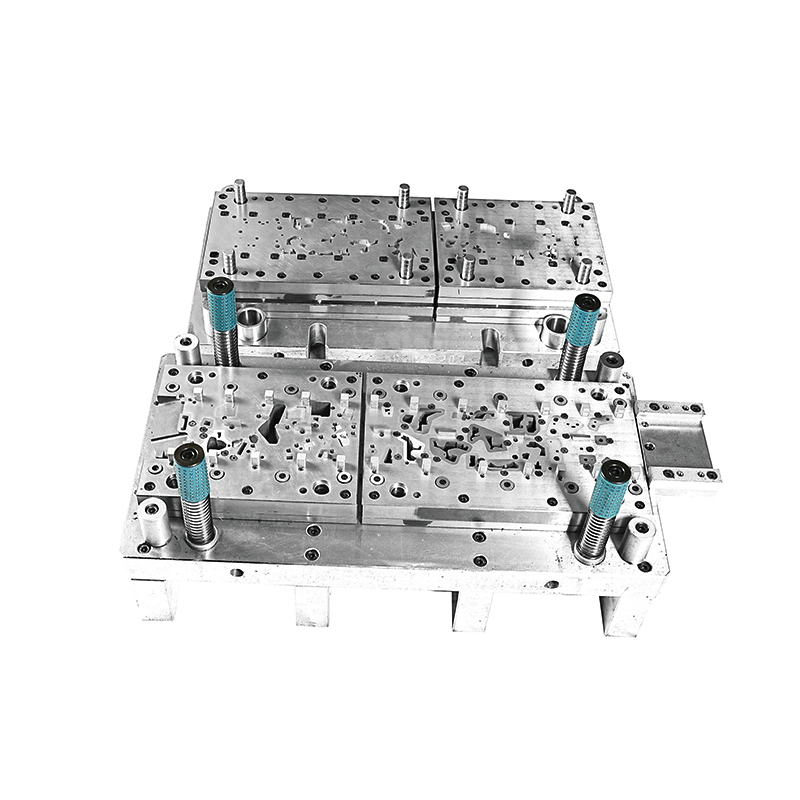

The high-precision shield cover continuous stamping die is a die specially used for the efficient and high-precision production of shield covers. It is mainly composed of a guide mechanism, a stamping working part, a discharge device and a feeding mechanism. Its working principle is to feed the metal material into the die at a precise length and speed through the feeding mechanism. Under the action of the press, the punch and the die cooperate to perform continuous punching, bending and other stamping processes on the material. After each stamping, the discharge device discharges the material, and the feeding mechanism feeds the material again, and the cycle operation is completed until the processing of the shield cover is completed. The die has the characteristics of high precision, high efficiency and high life. It can control the dimensional accuracy of the shield cover within a very small tolerance range. It is suitable for automated production and is widely used in the field of electronic equipment manufacturing. It is used to manufacture shield covers to prevent electromagnetic interference in electronic products such as mobile phones and computers.

Applications

High-precision shielding cover continuous stamping dies are mainly used in the field of electronic equipment manufacturing to produce shielding covers to prevent electromagnetic interference in various electronic equipment, such as consumer electronics, communication equipment, and automotive electronics.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.