Description

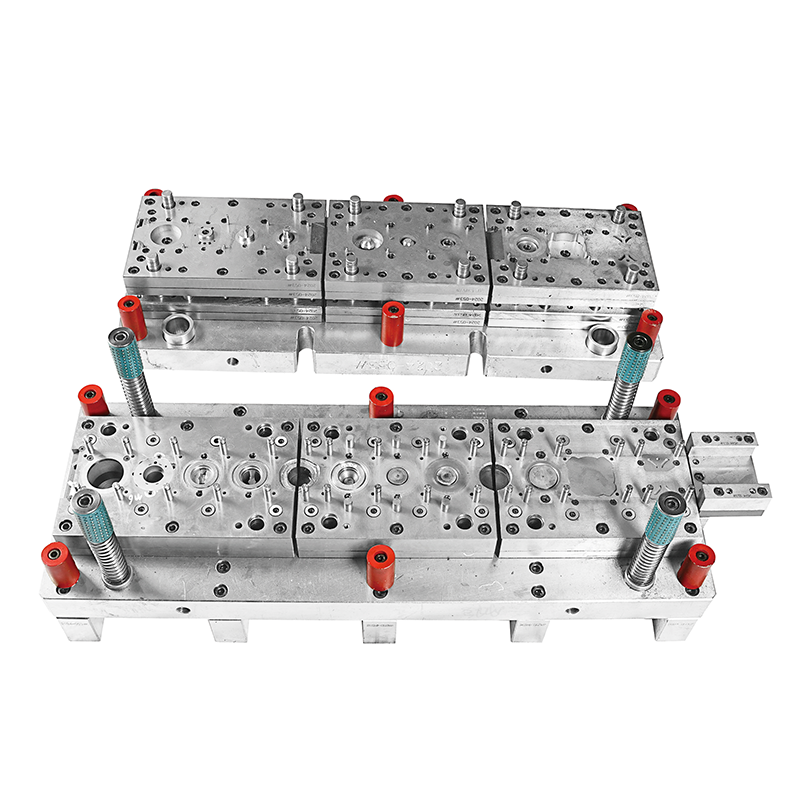

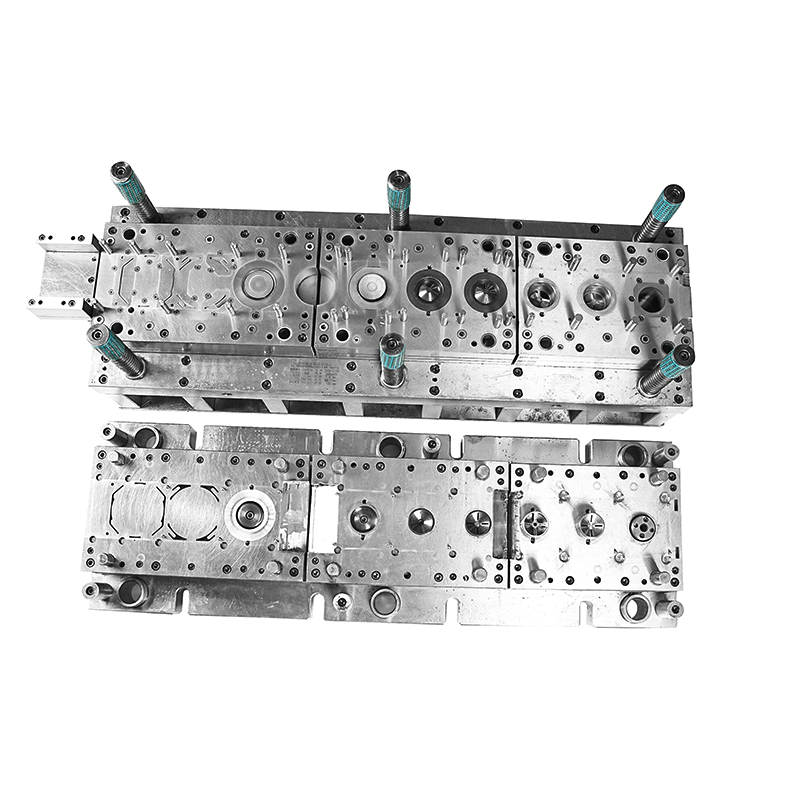

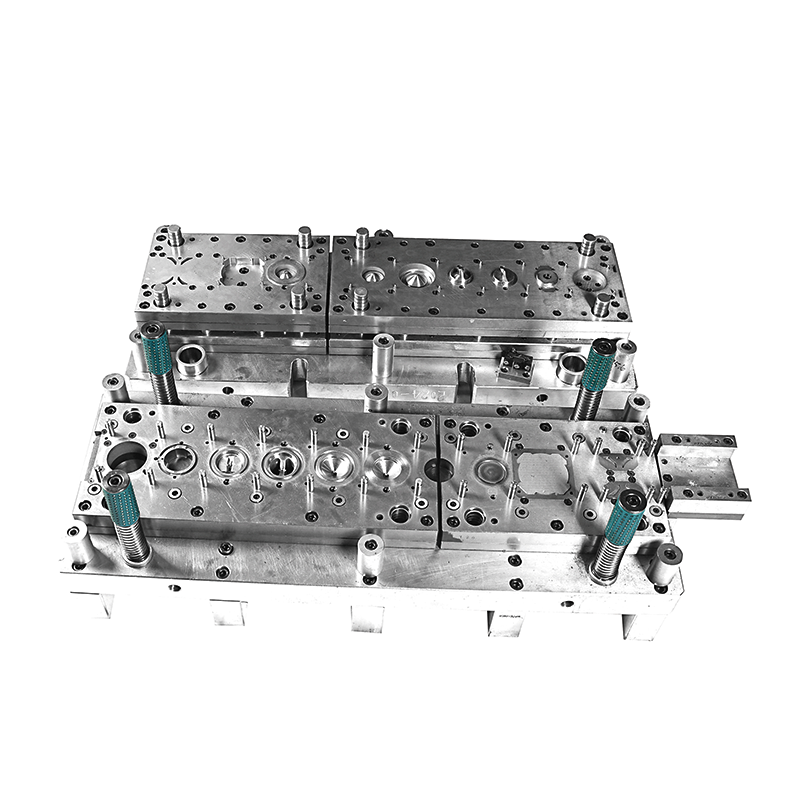

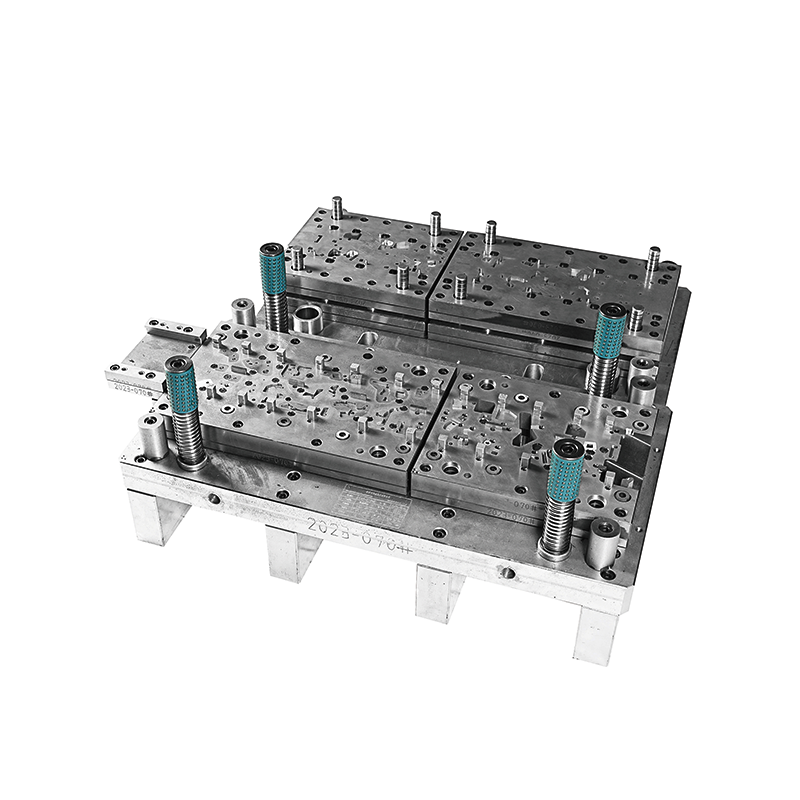

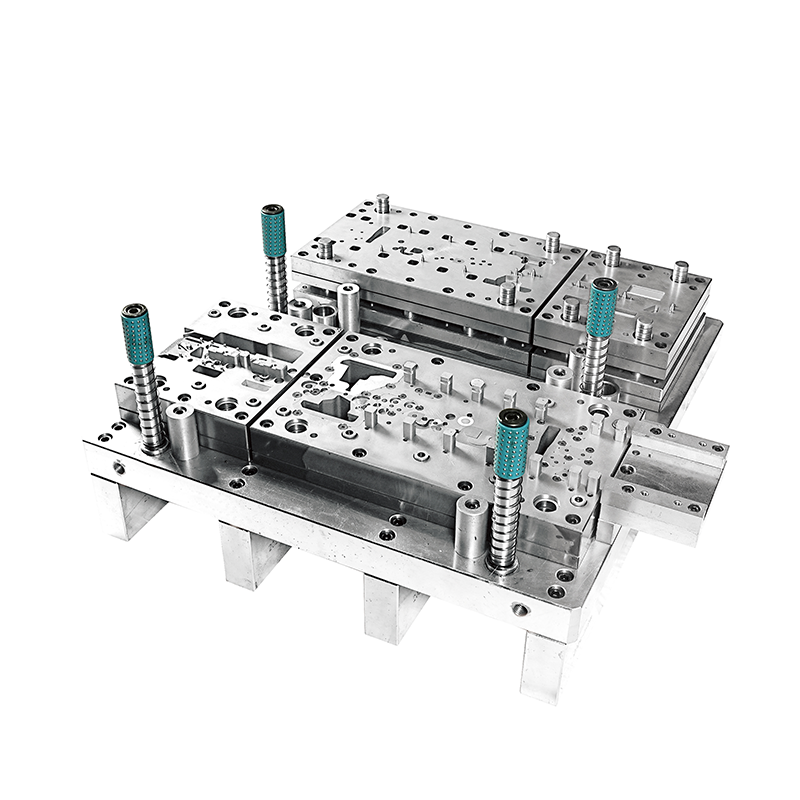

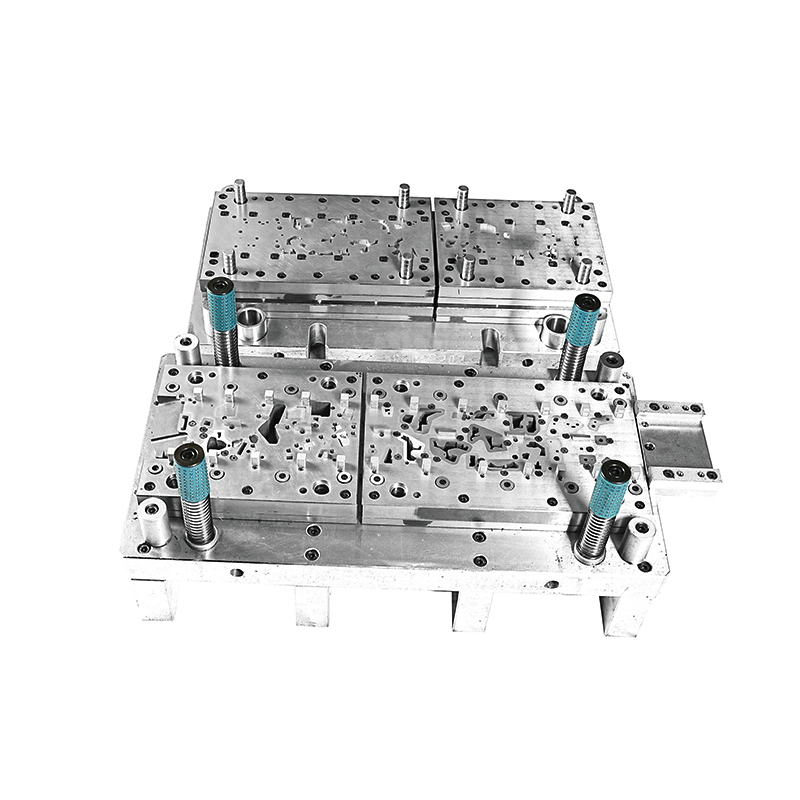

High-precision customized stretch stamping dies are dies that are designed and manufactured with high precision according to specific product requirements. They are used to process metal sheets into high-precision parts through stretching and stamping processes. Features

High precision: It can ensure the dimensional accuracy and shape accuracy of parts, and the tolerance is controlled within a very small range to meet the strict requirements of high-end products.

Customization: It can be customized according to the specific product design of the customer, and can achieve complex shapes and special structural requirements, which is highly targeted.

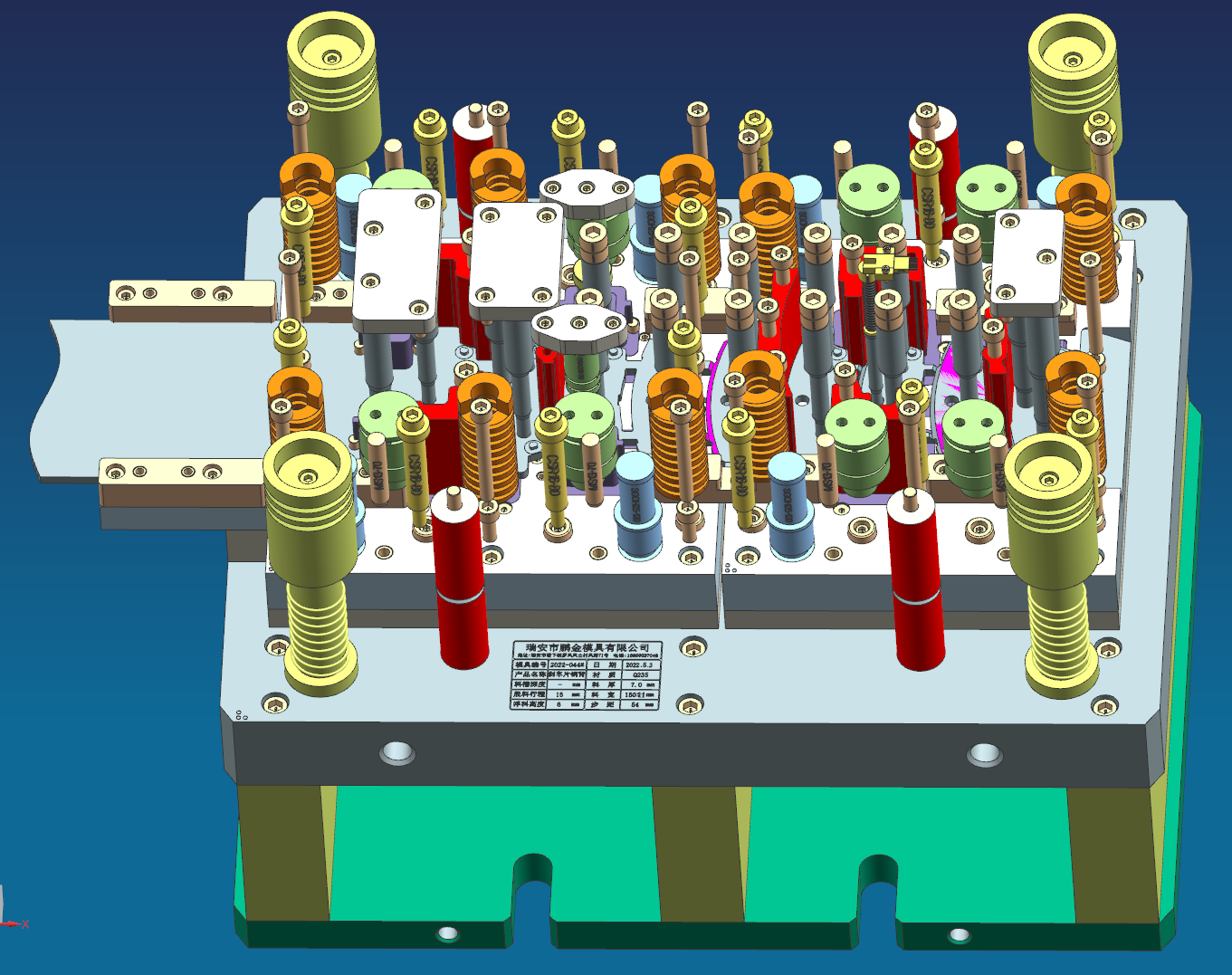

Structure: Similar to ordinary stretch stamping dies, it is usually composed of an upper die seat, a lower die seat, a punch, a die, a blank holder, a discharge device, a guide device, etc. However, it is more sophisticated in the design and manufacture of parts, and uses better quality materials and advanced processing technology to ensure the accuracy and life of the mold.

Working principle: The metal sheet is placed on the lower die seat of the mold and accurately fixed in position by a positioning device. The upper die seat moves downward under the action of the stamping equipment, and the punch enters the die, exerting pressure on the sheet to cause it to plastically deform, thereby achieving stretching and stamping. The blank holder prevents the sheet from wrinkling during the stretching process. The unloading device removes the workpiece from the punch after the stamping is completed, and then the feeding mechanism feeds the sheet to the next station for the next stamping. The cycle continues until the part is processed.

Applications

Mainly used in fields with high requirements for parts precision and customization, such as aerospace, precision instrument manufacturing, and high-end electronic equipment manufacturing. For example, some complex-shaped metal parts in the aerospace field and precision housings in high-end electronic equipment all require the use of high-precision customized stretch stamping dies to produce in order to ensure product quality and performance.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.