Description

Stamped parts for lighting switches refer to various parts and components made by stamping process and used to make lighting switches

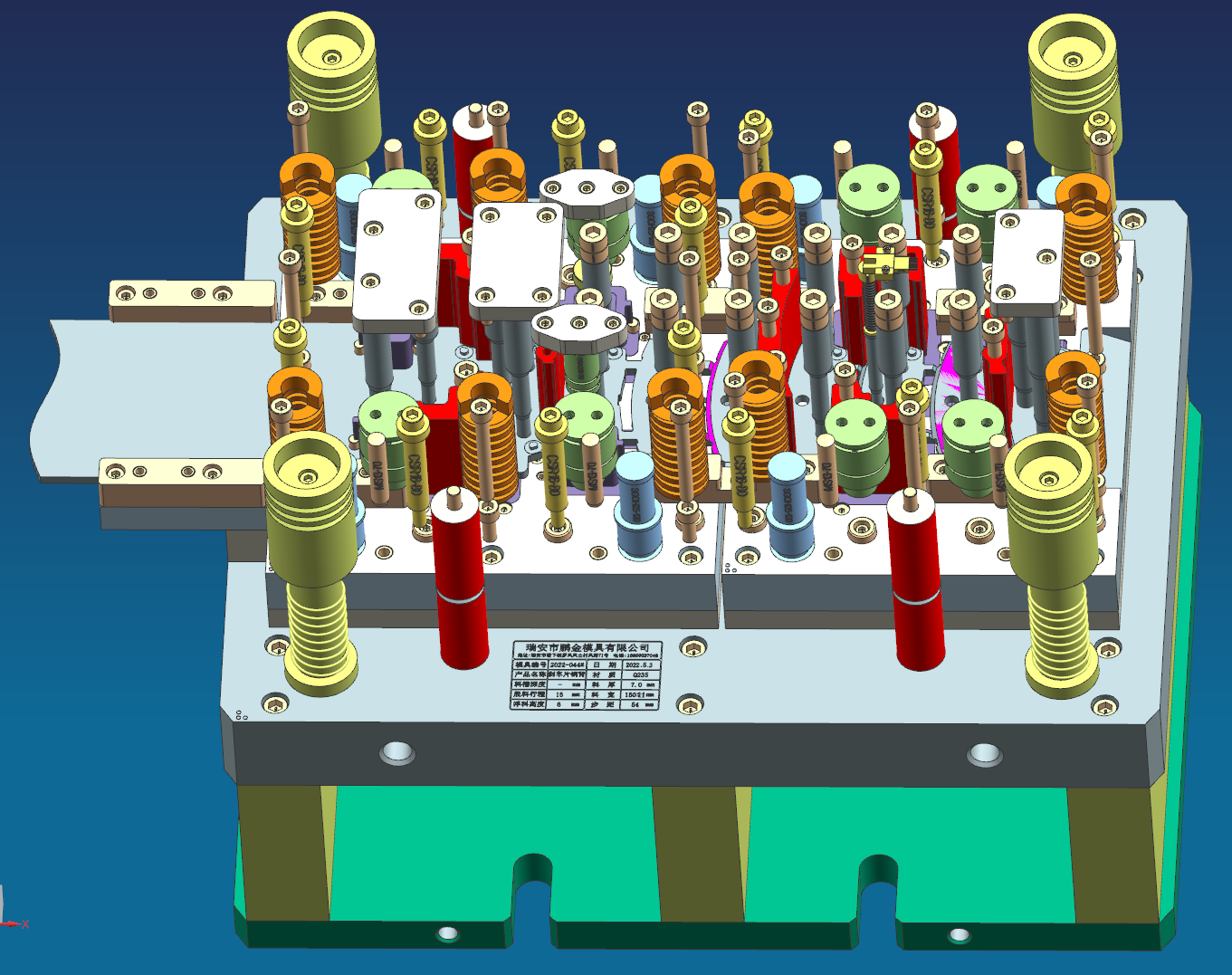

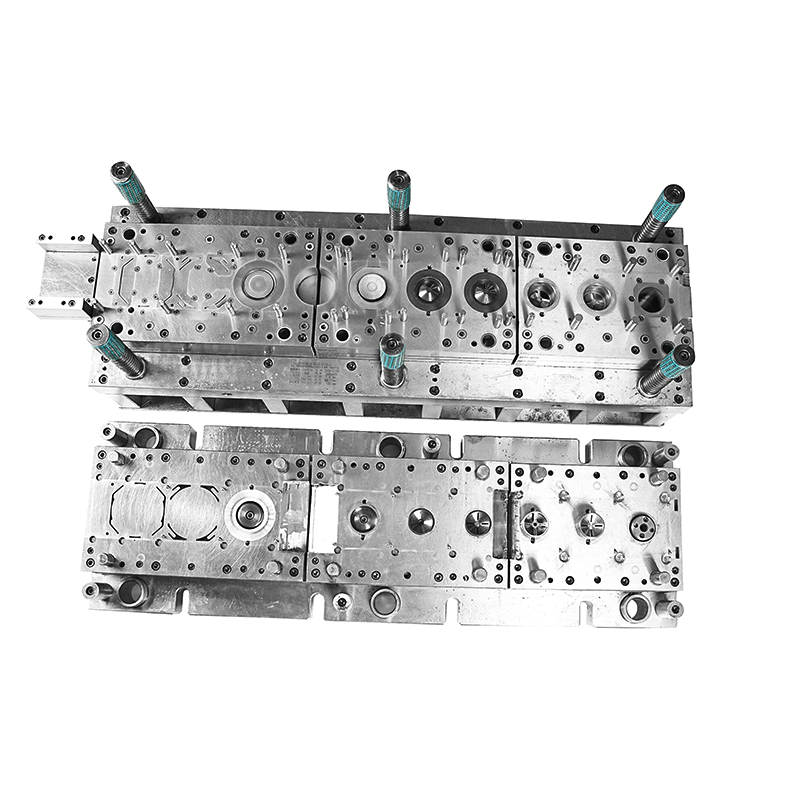

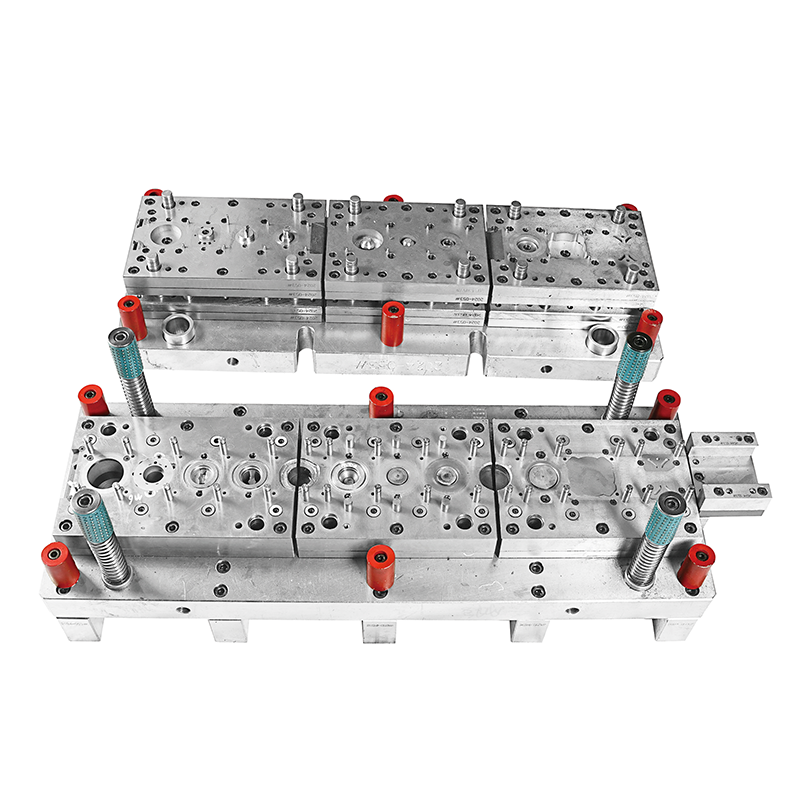

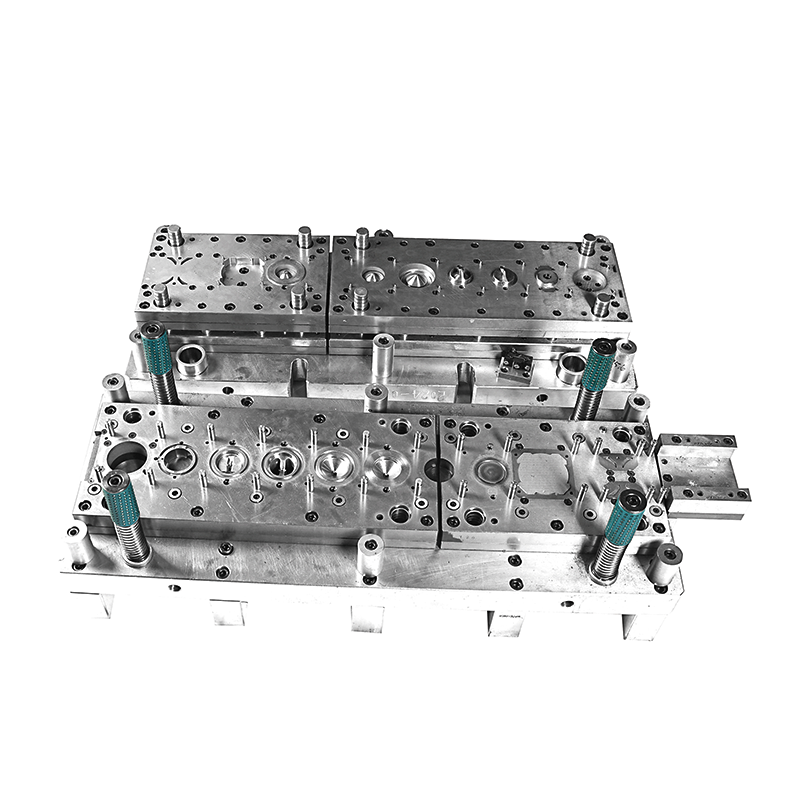

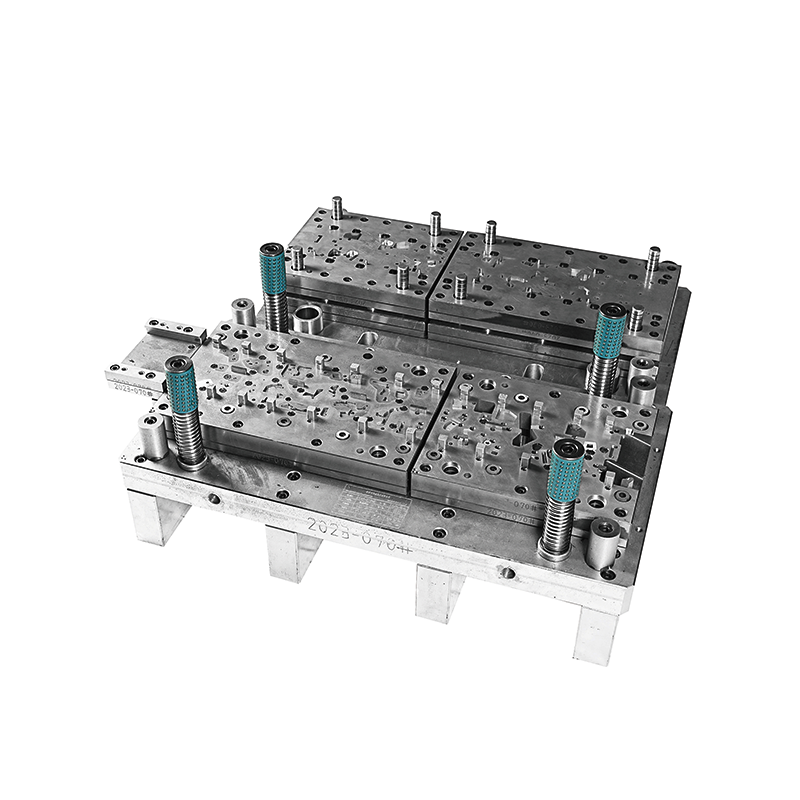

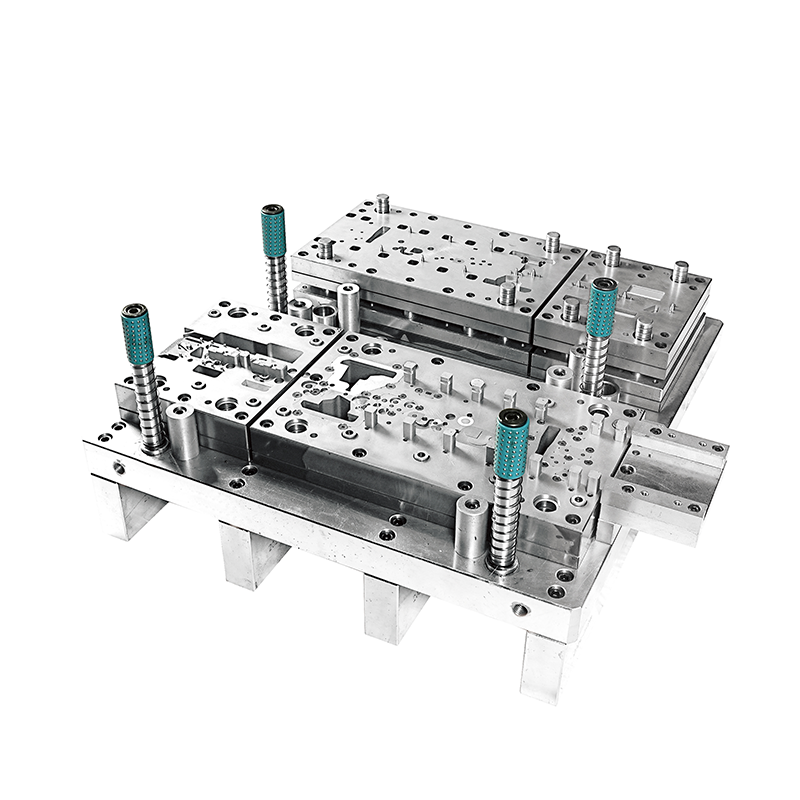

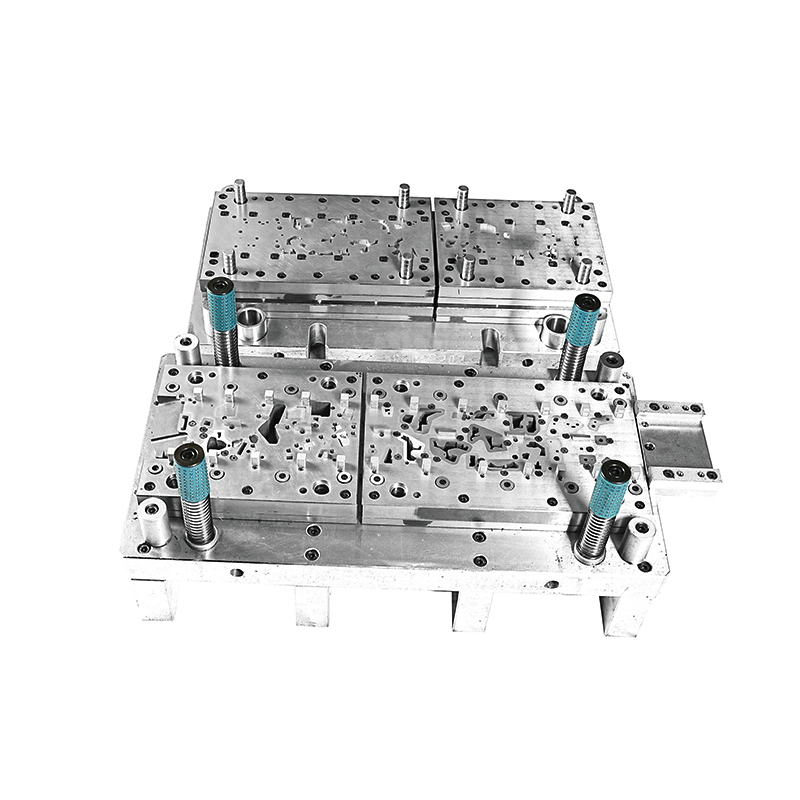

Manufacturing process: Similar to the stamped parts for electrical panels mentioned above, stamped parts for lighting switches also use stamping equipment and dies to stamp metal sheets. Through a series of stamping processes such as punching, bending, and stretching, the sheet is processed into parts with specific shapes, sizes, and precision requirements, such as switch bases, buttons, contact sheets, etc.

Common materials: Metal materials with good electrical conductivity, thermal conductivity, and mechanical properties are usually selected, such as copper alloys such as brass and phosphor bronze, as well as stainless steel, tinplate, etc. For some lighting switches with higher requirements, materials such as silver alloys may also be used to improve contact performance and electrical conductivity.

Function: Stamped parts for lighting switches are key components for lighting switches to realize their functions. Different parts have different functions. For example, the switch base provides support and fixation for other parts to ensure the stability of the overall structure of the switch; the button is the direct contact part operated by the user, and the circuit is controlled by pressing the button; the contact piece is the key component to achieve the conduction and disconnection of the circuit. It needs to have good conductivity and elasticity to ensure reliable contact and separation during frequent switching actions, thereby controlling the on and off of the lighting circuit and realizing the switch control of the lighting equipment.

Applications

They are widely used in various building lighting systems, home lighting equipment and industrial lighting fields.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.