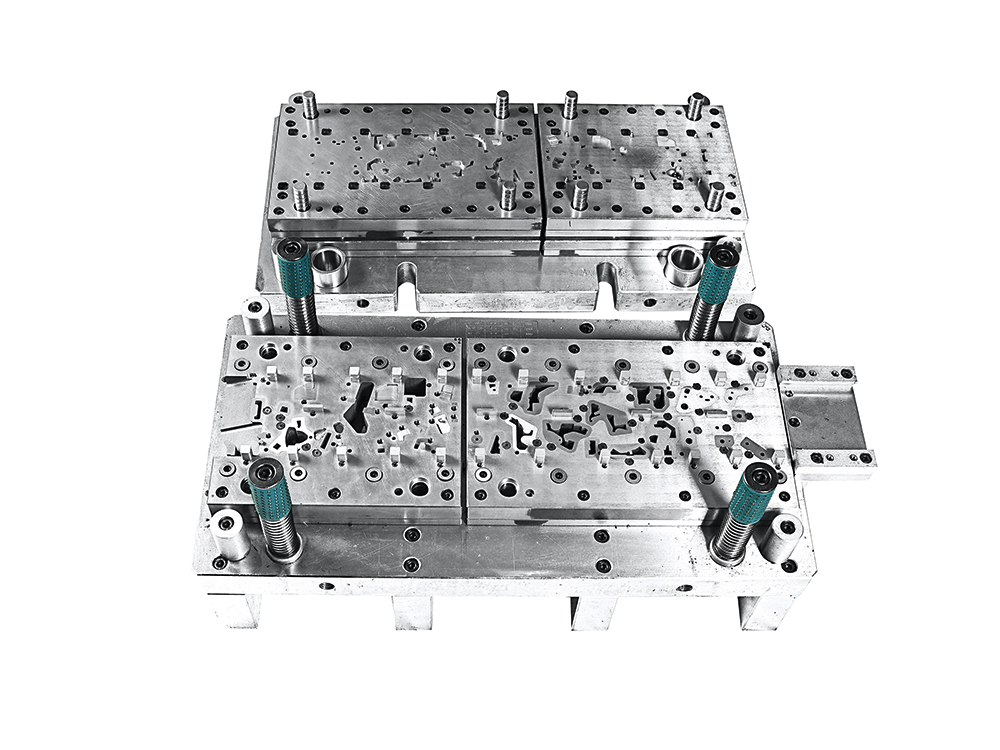

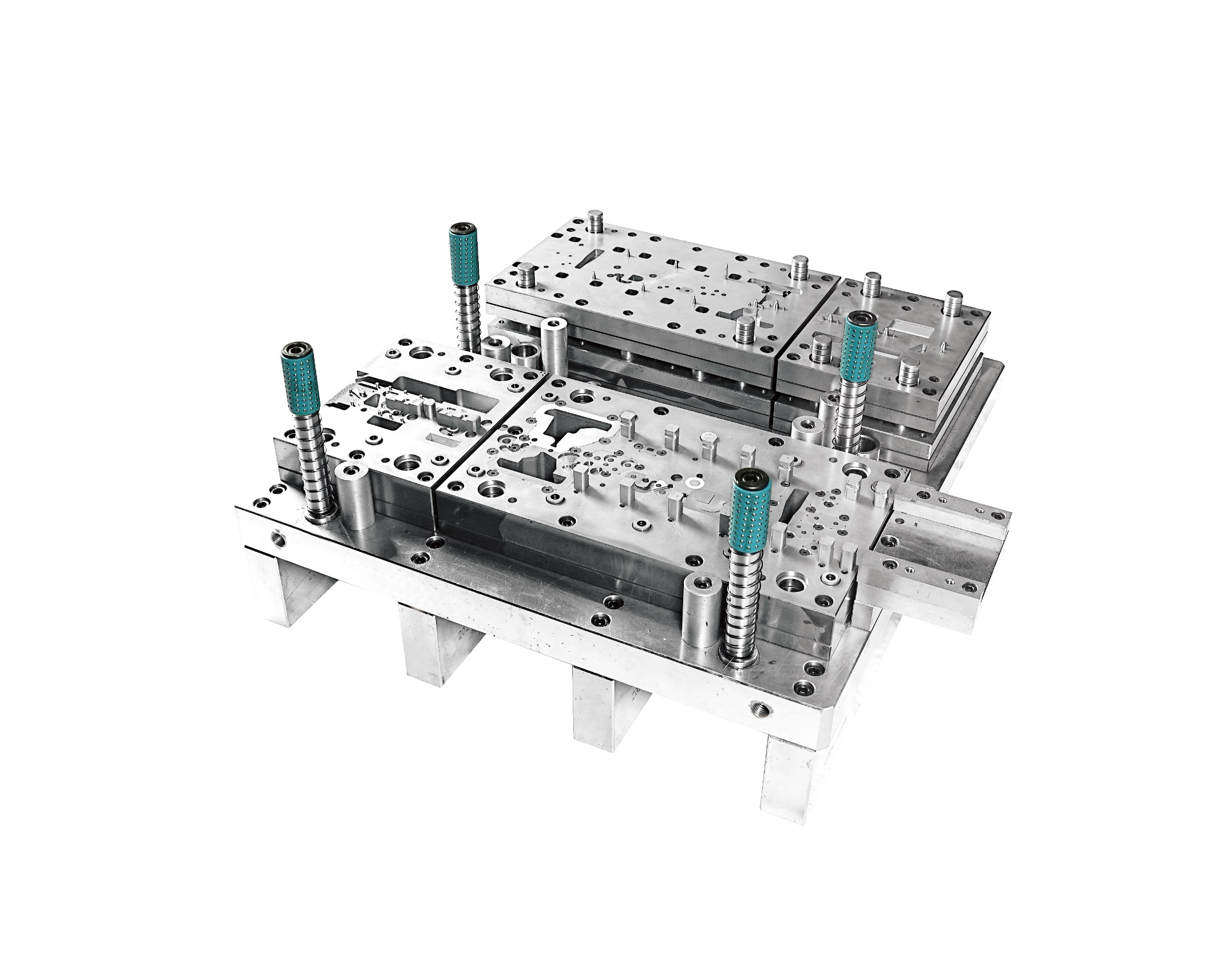

What are precision mold parts?

Precision stamping dies are usually composed of upper die base, lower die base, punch, die, guide device, unloading device and other components. During operation, the punch and die are pressed on the sheet by the pressure provided by the press and other equipment to obtain the required shape and size of the parts.

What are the characteristics of precision mold parts?

High precision: It can ensure the dimensional accuracy and form and position tolerance of the stamped parts. The general dimensional accuracy can reach ±0.01mm or even higher.

High surface quality: The surface of the stamped parts is smooth and the roughness is low, which can reduce the subsequent processing steps.

High efficiency: It can realize automated production, improve production efficiency and reduce production costs.

Long life: It adopts high-quality mold materials and advanced manufacturing processes, has high wear resistance and fatigue resistance, and has a long service life.

Complex shape processing capability: It can stamp out various complex shapes of parts to meet the design requirements of different products.

Precision mold parts are widely used in various industries, including:

Electronic information field: It is used to manufacture precision parts in electronic equipment such as mobile phones and computers, such as connectors, shielding covers, precision structural parts, etc.

Automobile manufacturing: manufacturing high-precision parts such as automobile engine parts, body structural parts, and automobile seat adjustment mechanisms.

Medical equipment: producing various precision parts in medical equipment, such as surgical instruments, dental instruments, and medical equipment housings.

Aerospace: manufacturing high-precision and high-strength parts such as aircraft engine blades and aircraft structural parts.

Home appliance: used to manufacture precision parts in home appliances such as air conditioners, refrigerators, and washing machines, such as compressor parts and home appliance housings.

Why choose precision mold parts?

Guarantee product precision: The processing precision of precision mold parts is extremely high, which can ensure that the products produced are accurate in size and regular in shape, meeting strict design requirements. In fields such as electronics and aerospace that have strict requirements on product precision, the use of precision mold parts can produce products with dimensional tolerances at the micron level, thereby ensuring the stability and consistency of product performance.

Improve product quality: Precision mold parts have good surface quality and low roughness, which can make the product surface smooth and flawless. At the same time, its advanced manufacturing process can effectively control the deformation and residual stress of the mold, avoid defects such as cracks and pores during the product molding process, and thus improve the overall quality and reliability of the product.

Improve production efficiency: The design and manufacturing of precision mold parts fully consider the automation requirements in the production process, and have good interchangeability and assembly accuracy. This makes the installation, commissioning and maintenance of the mold more convenient, which can reduce downtime and improve production efficiency. In addition, precision mold parts have a long service life and can maintain stable performance during a long production process, reducing the frequency of mold replacement and further improving production efficiency.

Reduce production costs: Although the initial purchase cost of precision mold parts is relatively high, in the long run, due to their long service life and high production efficiency, they can reduce the unit production cost of products. At the same time, the use of precision mold parts can reduce the scrap rate and defective rate of products, reduce the cost increase caused by product quality problems, and thus achieve a reduction in total costs.

Meet the needs of complex products: With the continuous development of science and technology, the structure and function of products are becoming more and more complex. Precision mold parts have strong adaptability and flexibility, and can manufacture molds of various complex shapes and structures through advanced processing technology to meet the production needs of different types of products, such as complex parts with tiny holes, narrow grooves, thin walls and other features.