What is a sheet metal fabricator?

Sheet metal processing manufacturers are companies that specialize in the processing and production of sheet metal products.

What are the business scope, processing technology, equipment and technology of sheet metal processing manufacturers?

Business scope

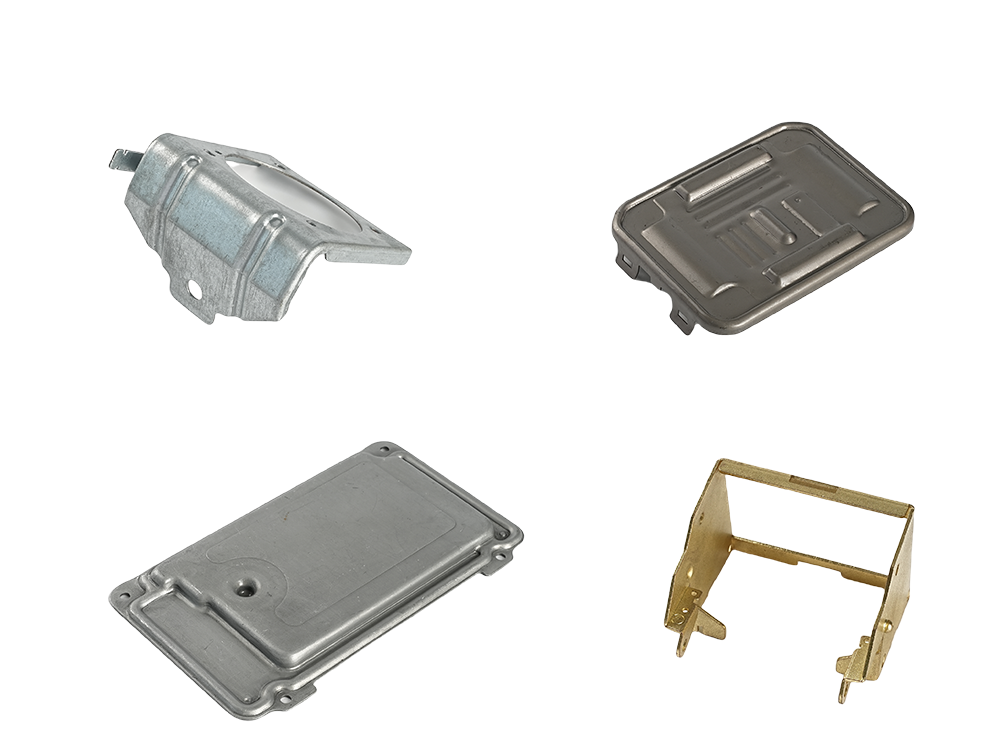

Product manufacturing: covers all kinds of sheet metal products, such as electronic equipment housings, chassis cabinets, auto parts, kitchen equipment, architectural decorative components, etc. According to customer needs, customized production can be carried out from simple flat parts to complex assembly parts.

Design and R&D: Some strong manufacturers also have product design and R&D capabilities. According to the concepts or sketches provided by customers, they can use professional design software to carry out detailed design of sheet metal parts, including structural design, strength calculation, process planning, etc., to ensure that the product has good machinability and economy while meeting functional requirements.

Processing technology

Cutting and blanking: Use laser cutting, CNC flame cutting, plasma cutting and other processes to accurately cut sheet metal plates into the required blank shape according to the designed size. Among them, laser cutting has the advantages of high precision, smooth cutting surface, and small heat-affected zone. It is suitable for cutting plates of various thicknesses, especially thin plate cutting.

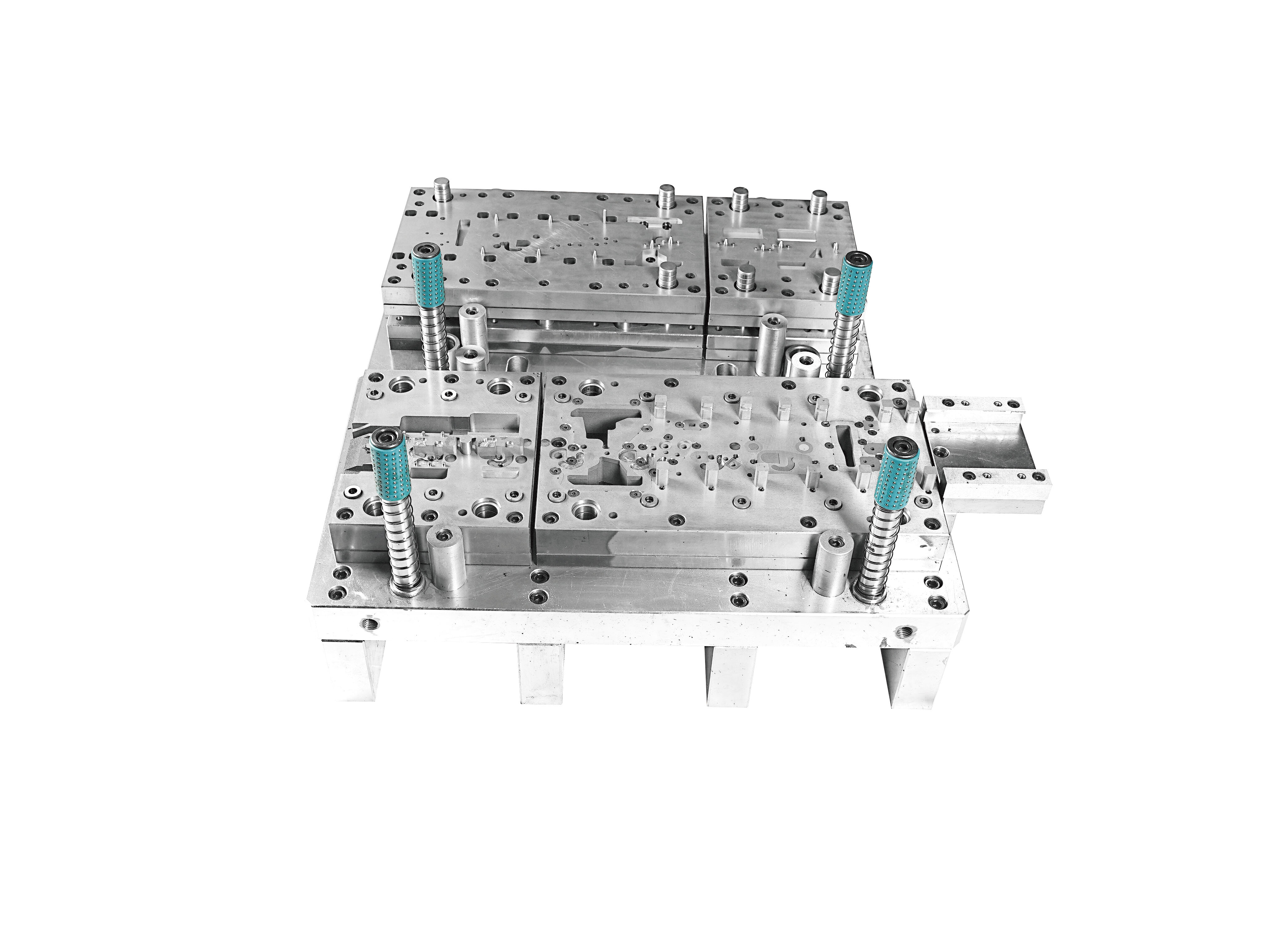

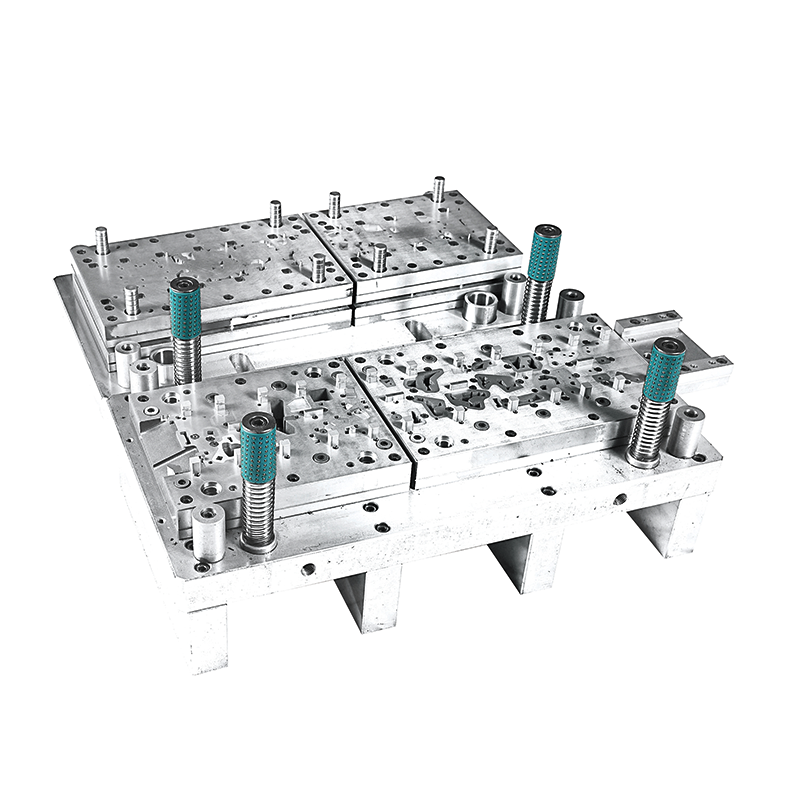

Bending and forming: Use CNC bending machines to bend the cut sheet metal parts, and make the sheet metal parts reach the designed shape by accurately controlling the bending angle, radius and length. For some complex curved structures, multi-step bending or special molds may be required to achieve it.

Welding assembly: Use spot welding, arc welding, laser welding and other welding methods to connect various sheet metal parts into complete products. The quality of welding directly affects the strength and sealing of the product. Manufacturers usually have strict welding process specifications and quality inspection methods to ensure the quality of welded joints.

Surface treatment: In order to improve the corrosion resistance, wear resistance and aesthetics of sheet metal parts, surface treatment processes such as electroplating, spraying, oxidation, etc. will be carried out. Electroplating can improve the hardness and corrosion resistance of the surface of parts, spraying can provide good decorative and protective properties, and oxidation treatment is often used for aluminum products, which can enhance their surface hardness and weather resistance.

Equipment and technology

Advanced equipment: It has a series of advanced CNC processing equipment, such as CNC punching machines, CNC bending machines, laser cutting machines, automated welding robots, etc. These equipment can achieve high-precision and high-efficiency processing, reduce manual operation errors, and improve product quality and production efficiency.

Manufacturing technology: Continuously introduce and apply advanced sheet metal processing technologies, such as flexible manufacturing system (FMS), computer-aided design and manufacturing (CAD/CAM) technology, etc. FMS can realize the automated production of multi-variety and small batch products, and CAD/CAM technology can realize the integration from product design to processing and manufacturing, improving production efficiency and processing accuracy.

Quality control

Raw material inspection: Strict inspection of purchased sheet metal plates, including chemical composition, mechanical properties, surface quality and other aspects of the materials, to ensure that the raw materials meet the quality requirements of the products.

Process inspection: During the processing, the first piece inspection, patrol inspection and finished product inspection are used to monitor the processing quality of each process. Through three-coordinate measuring instruments, roughness testers and other testing equipment, the dimensional accuracy, form and position tolerance, surface quality, etc. of the products are accurately measured to timely discover and correct quality problems in the processing process.

Finished product inspection: After the product is processed, a comprehensive finished product inspection is carried out, including appearance inspection, dimensional accuracy inspection, performance testing, etc. Only products that pass strict inspection can be put into storage and delivered to customers to ensure that the delivered products meet quality standards and customer requirements.

Why Choose Us?

Excellent processing capabilities: We have advanced processing equipment, including high-precision laser cutting machines, CNC bending machines and punching machines, etc., which can realize sheet metal processing with various complex shapes and high-precision requirements. Whether it is a tiny electronic device housing or a large industrial equipment cabinet, we can ensure product quality with excellent craftsmanship.

Rich industry experience: In the field of sheet metal processing, we have accumulated many years of experience and have served many customers in different industries, such as electronics, automobiles, aerospace, etc. This gives us an in-depth understanding of the needs and standards of different industries and can provide professional solutions according to the specific requirements of customers.

Strict quality control: We have established a complete quality control system, from raw material procurement to every link of the production process, and then to the inspection of the final product, there are strict standards and processes. Through advanced testing equipment, such as three-coordinate measuring machines, etc., the products are accurately tested to ensure the dimensional accuracy and quality stability of the products, so that customers can use our products with confidence.

Customized service: We are well aware that each customer has unique needs, so we provide highly customized services. Our professional design team can work closely with customers to tailor the most suitable sheet metal products for customers from product concept design to detailed process planning, helping customers achieve product innovation and differentiation.

Efficient production efficiency: With the help of optimized production processes and advanced equipment automation, we are able to achieve efficient production and shorten product delivery cycles. At the same time, we have the ability to flexibly respond to emergency orders and batch orders to ensure that customers can get the required products in a timely manner to meet the rapid changes in the market and the urgent needs of customers.

High-quality customer service: We are customer-centric and provide high-quality pre-sales, in-sales and after-sales services. In the early stage of the project, our sales team and technical personnel will fully communicate with customers, understand customer needs, and provide professional advice and solutions; during the production process, timely feedback to customers on the progress of the project; after product delivery, provide perfect after-sales service, respond to customer questions and needs in a timely manner, and provide customers with all-round support.

Good cost control: By optimizing raw material procurement channels, improving material utilization and production efficiency, we can effectively control costs and provide customers with competitive prices while ensuring product quality, helping customers reduce production costs and improve the market competitiveness of products.