Description

Circuit board connector parts are electronic components used to achieve electrical connection and signal transmission between circuit boards or between circuit boards and other electronic devices.

Structural type: Circuit board connector parts have various structural forms, the most common ones are plugs and sockets. Plugs generally have protruding pins or pins for inserting into corresponding sockets. Sockets have jacks or slots that match the plugs and can provide stable electrical connections. In addition, there are types such as pin headers and mother headers, which usually have multiple pins or jacks arranged in a straight line, which can realize the transmission of multiple signals at the same time and are often used to connect electronic components or circuit boards with multiple pins. There are also board-to-board connectors, which are used to achieve vertical or horizontal connections between two printed circuit boards. Their structural design can ensure high-density electrical connections in a limited space.

Manufacturing materials: The contact part of the connector usually uses metal materials with good conductivity and wear resistance, such as copper alloy (phosphor bronze, brass, etc.), and the surface is generally plated with gold, silver, tin and other metals to further improve conductivity and corrosion resistance, reduce contact resistance, and ensure reliable electrical connection. The insulating part uses engineering plastics with good insulation performance, high temperature resistance and mechanical strength, such as polyamide (PA), polyphenylene sulfide (PPS), etc. These materials can effectively isolate the electrical signals between different pins to prevent short circuits, and can withstand certain mechanical stress and thermal stress.

Function: The main function of the circuit board connector components is to provide reliable electrical connection and signal transmission channels, facilitate the connection and disassembly between the circuit board and other electronic components and equipment, and facilitate the assembly, debugging and maintenance of electronic equipment. Widely used in electronic equipment, such as various interfaces on the computer motherboard, including CPU sockets, memory slots, USB interfaces, etc., are all circuit board connector components. They ensure that data and power can be transmitted stably between various hardware components, so that the computer can operate normally.

Applications

In mobile devices such as mobile phones and tablets, there are also a large number of connectors used to connect display screens, cameras, batteries and other components to achieve electrical connections and signal transmission within the device. In addition, in many fields such as industrial control, communication equipment, and automotive electronics, circuit board connector components are key components for achieving interconnection between various parts of complex electronic systems.

FAQ

Q: Are you a factory or trading company?

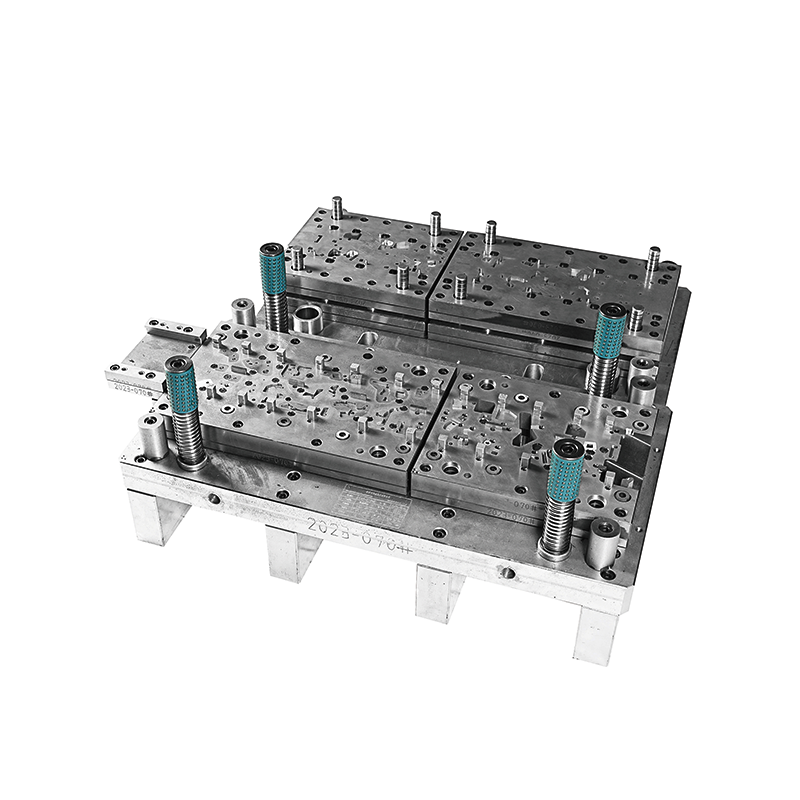

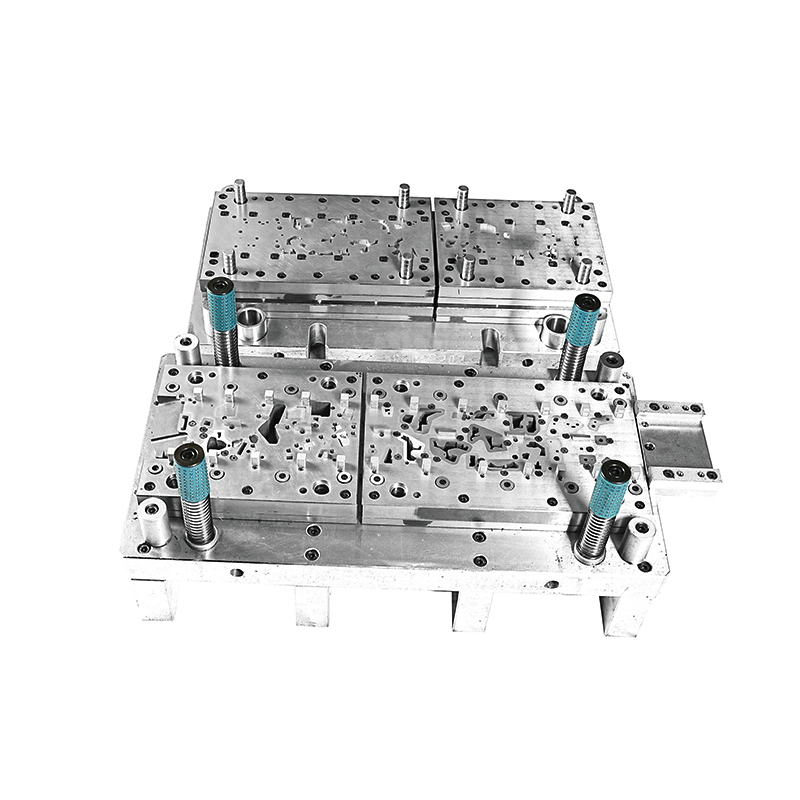

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

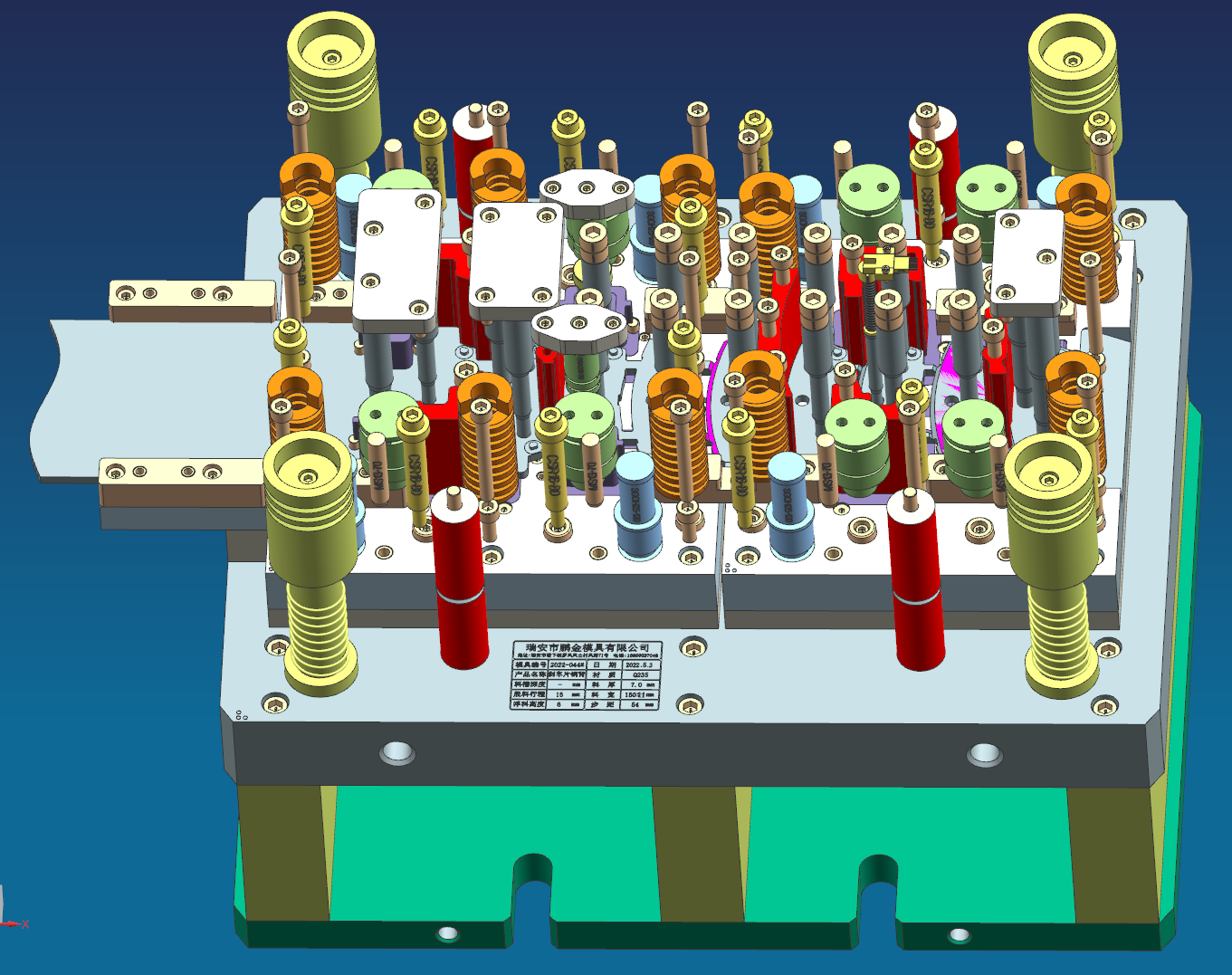

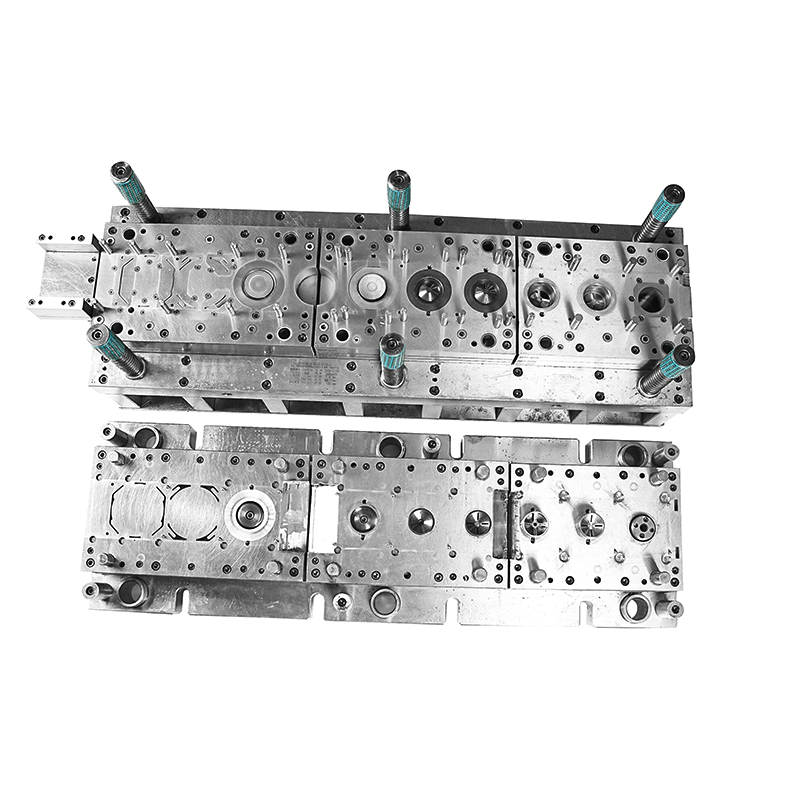

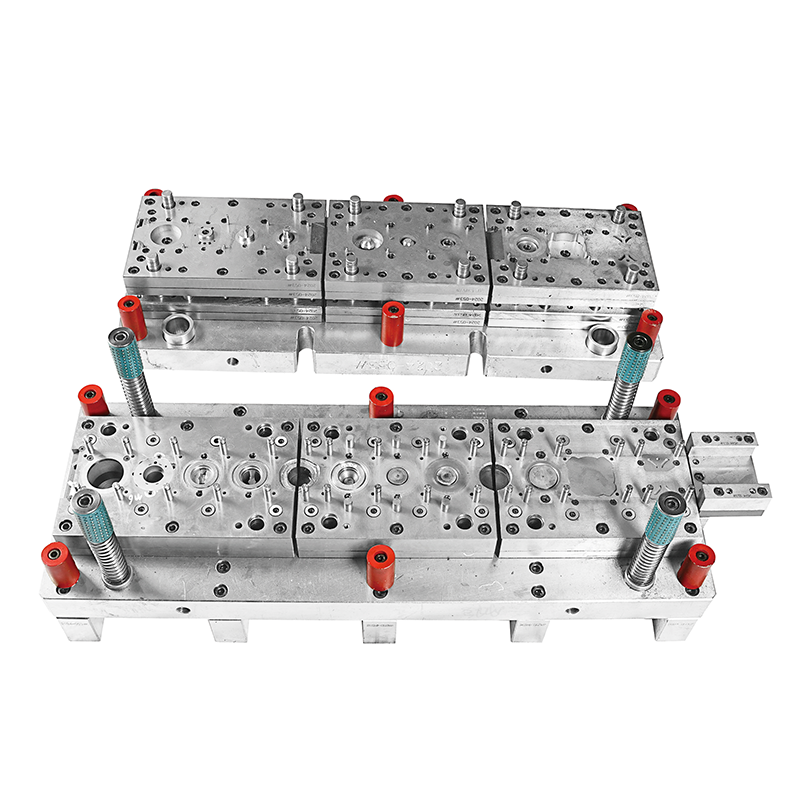

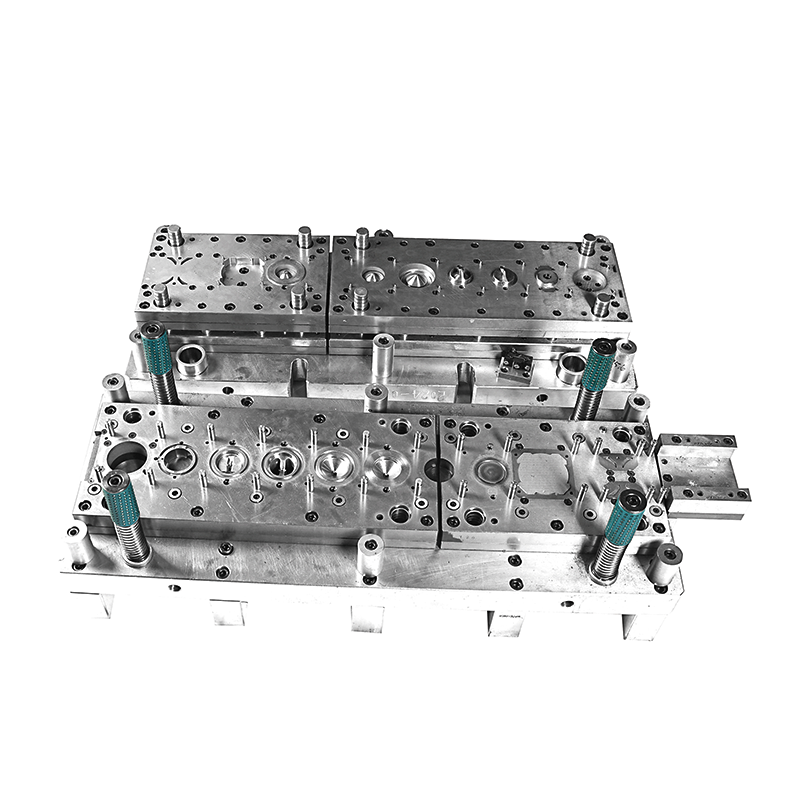

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

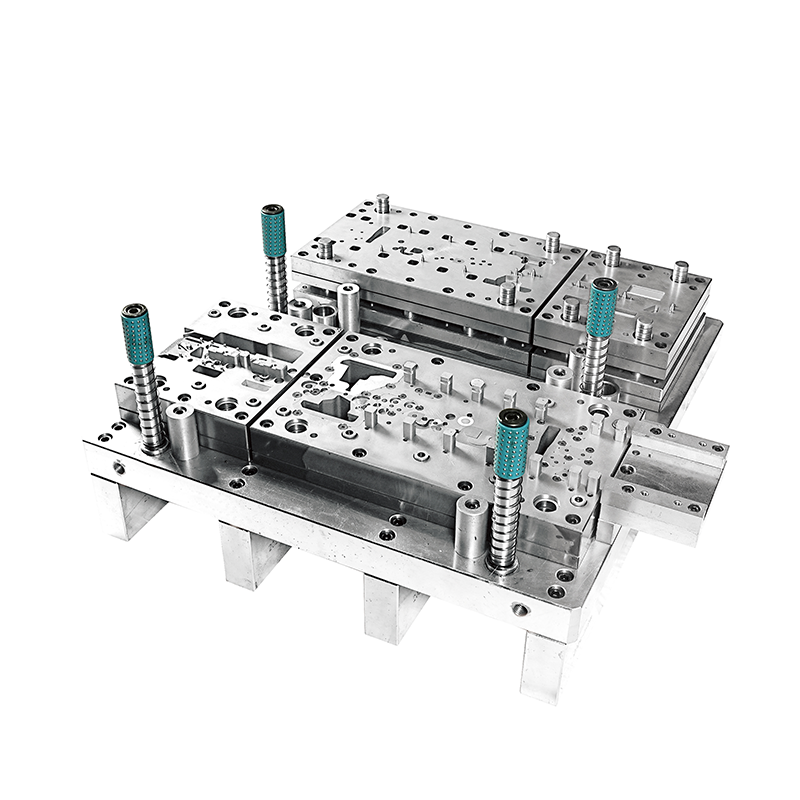

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.