Description

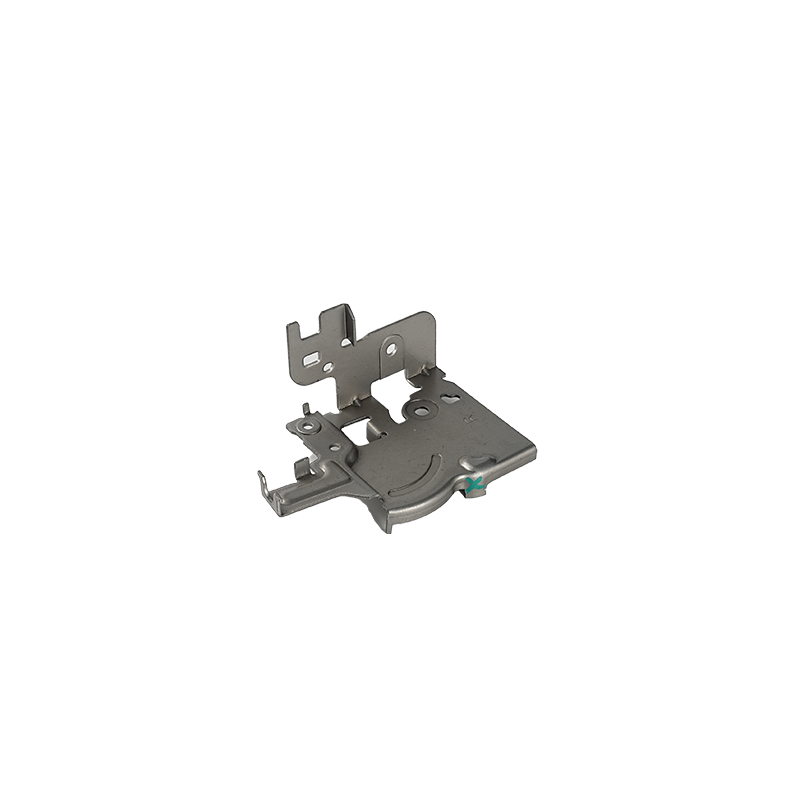

Door lock stamping parts refer to metal parts that are manufactured through stamping process and used to form various door lock mechanisms

Function: Door lock stamping parts are the key parts to realize the door lock function. They cooperate with each other to realize the door locking, opening, insurance and other functions, ensure the safety and convenience of use of the door, and meet the durability requirements under different environments and usage requirements.

Material: Commonly used materials include high-quality carbon steel, stainless steel, copper alloy, etc. High-quality carbon steel has good stamping performance and certain strength, which can meet the use requirements of general door locks, and the cost is relatively low; stainless steel has excellent corrosion resistance and high strength, and is suitable for environments with high requirements for door lock durability and appearance, such as humid environments or outdoors; copper alloy has good electrical conductivity, thermal conductivity and corrosion resistance, and beautiful appearance, and is often used in high-end door lock products.

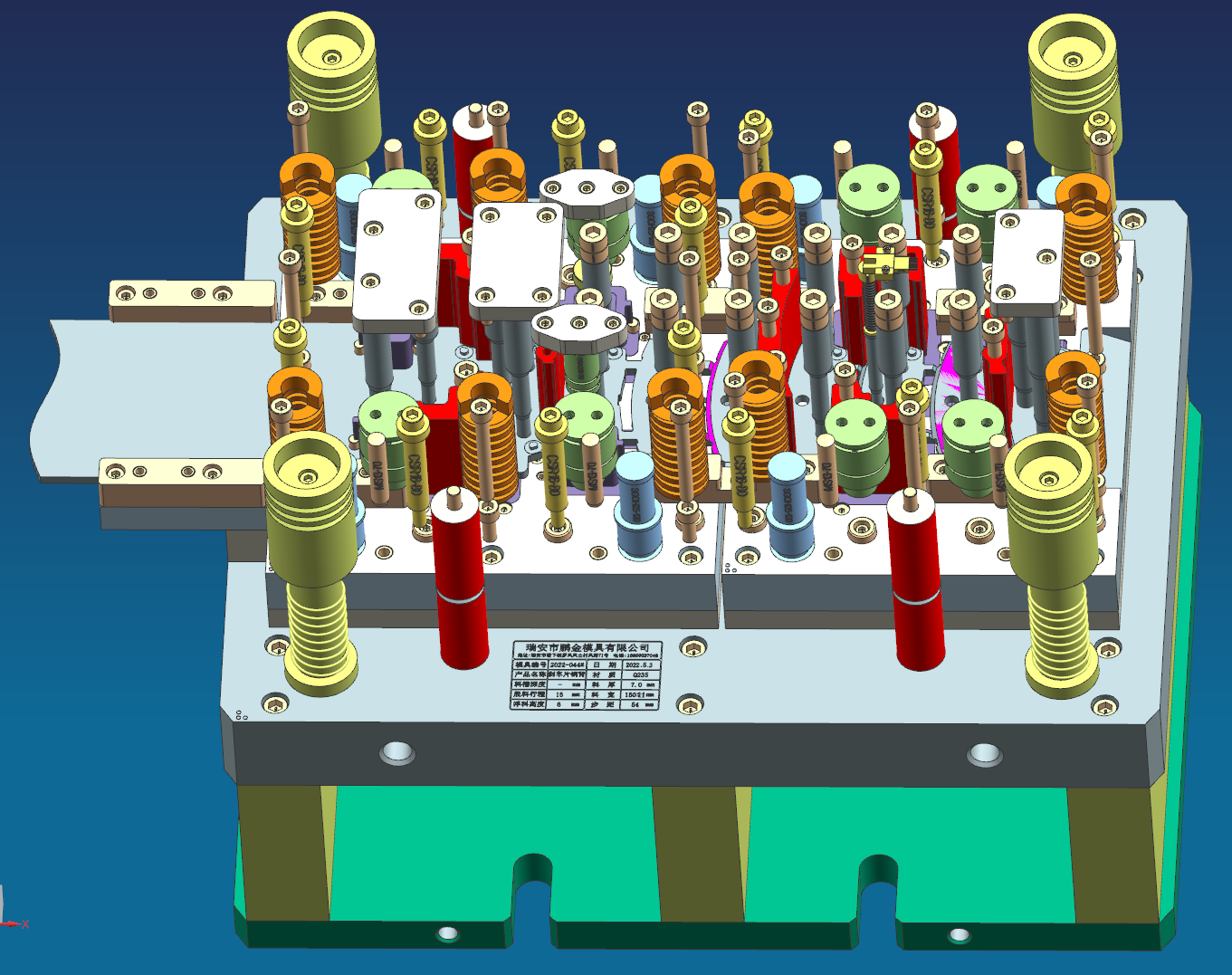

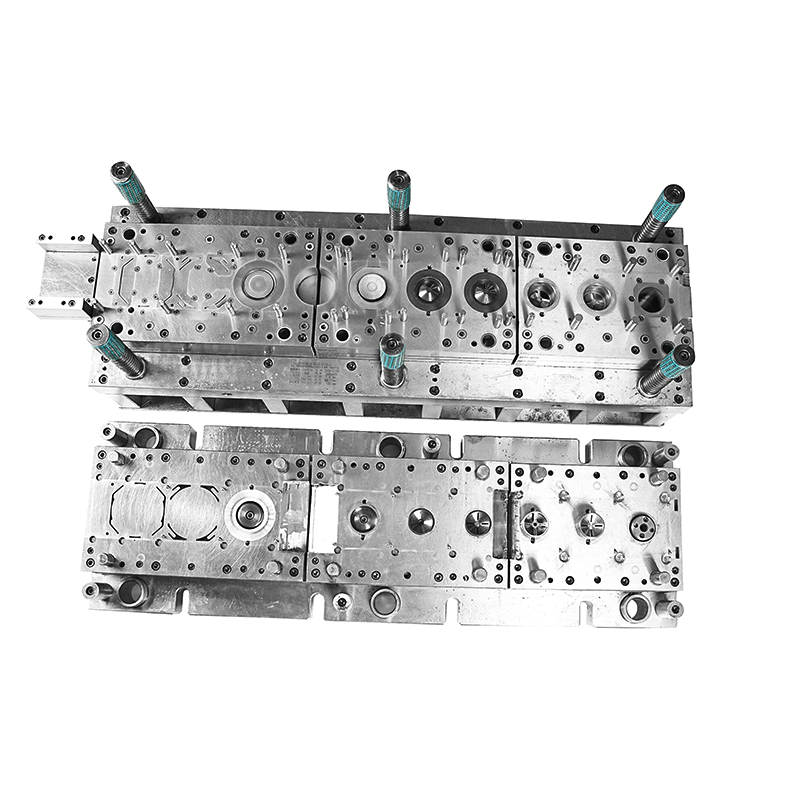

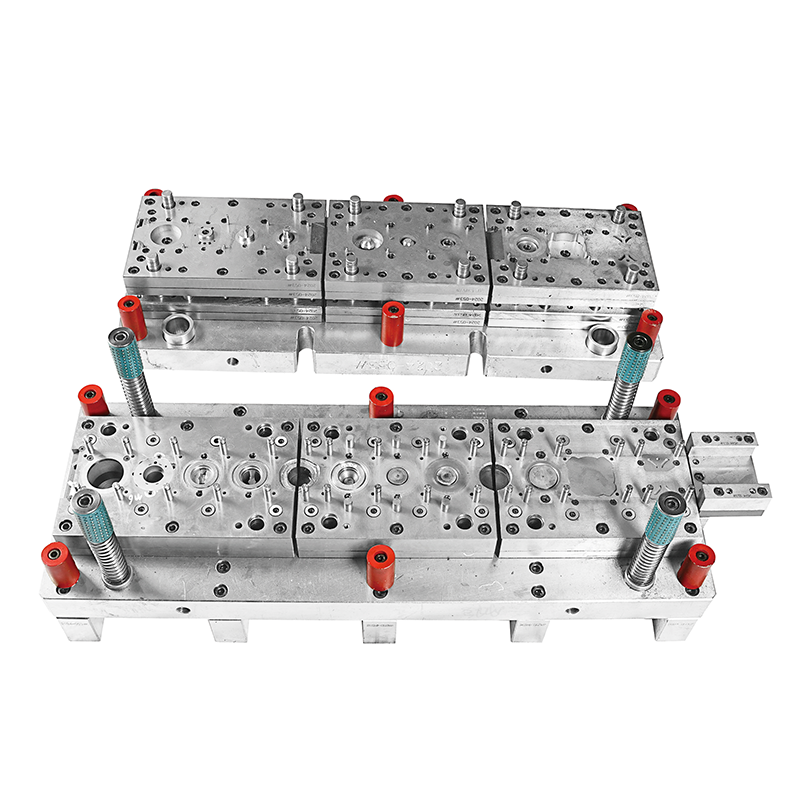

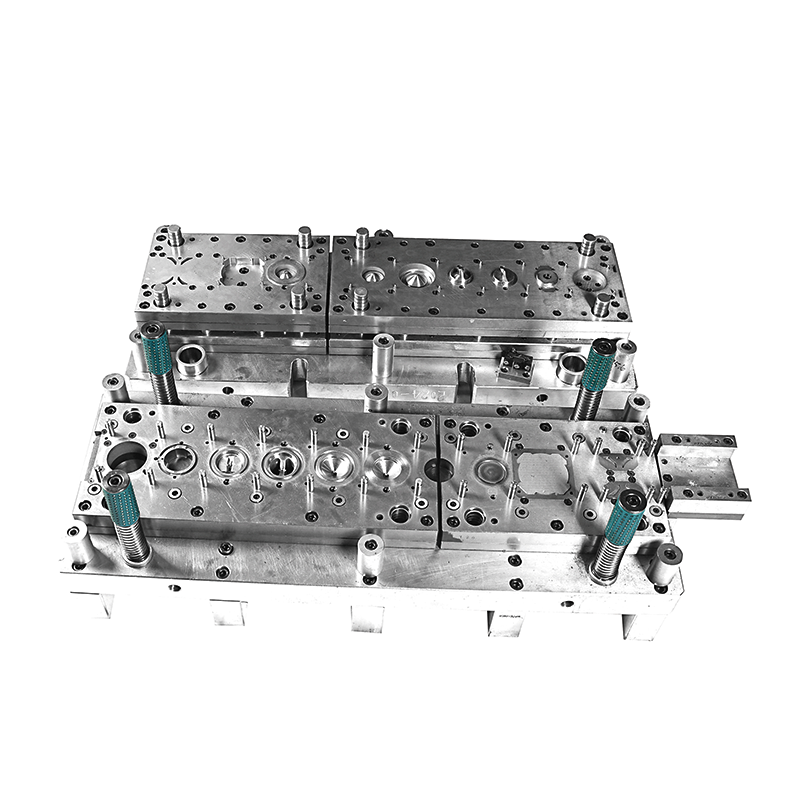

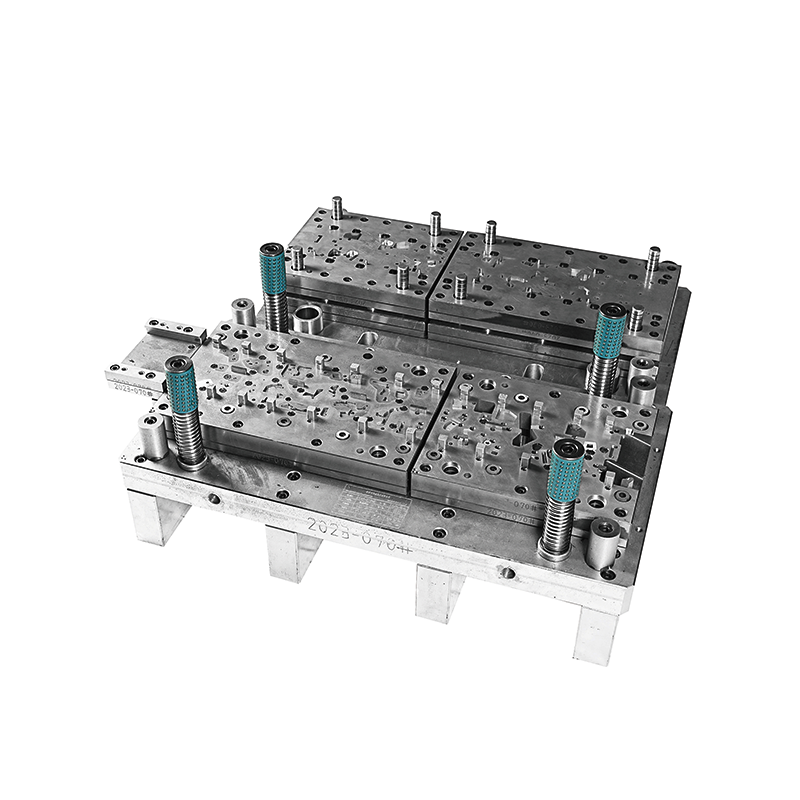

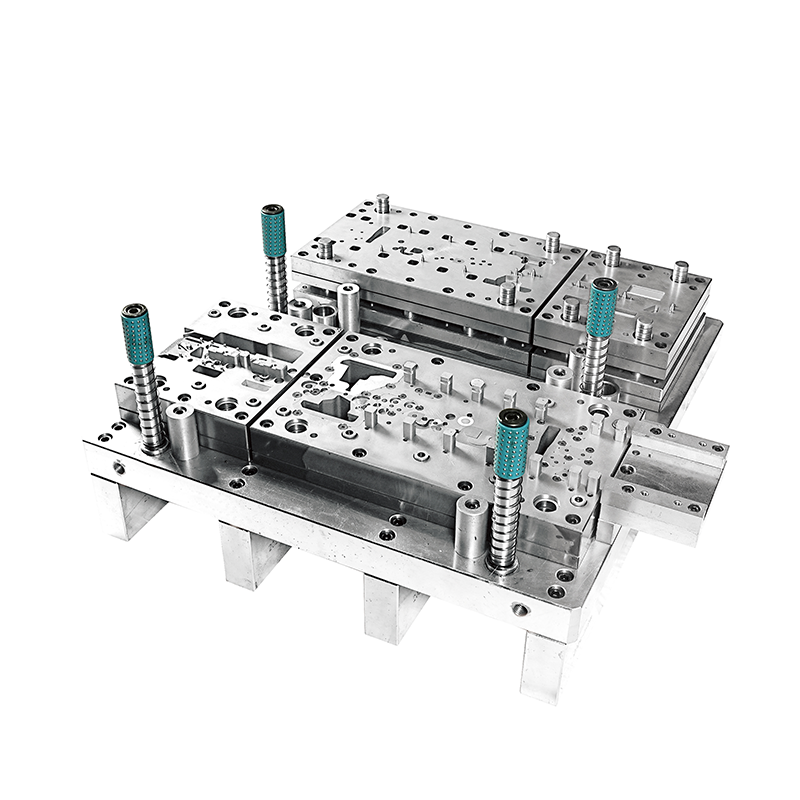

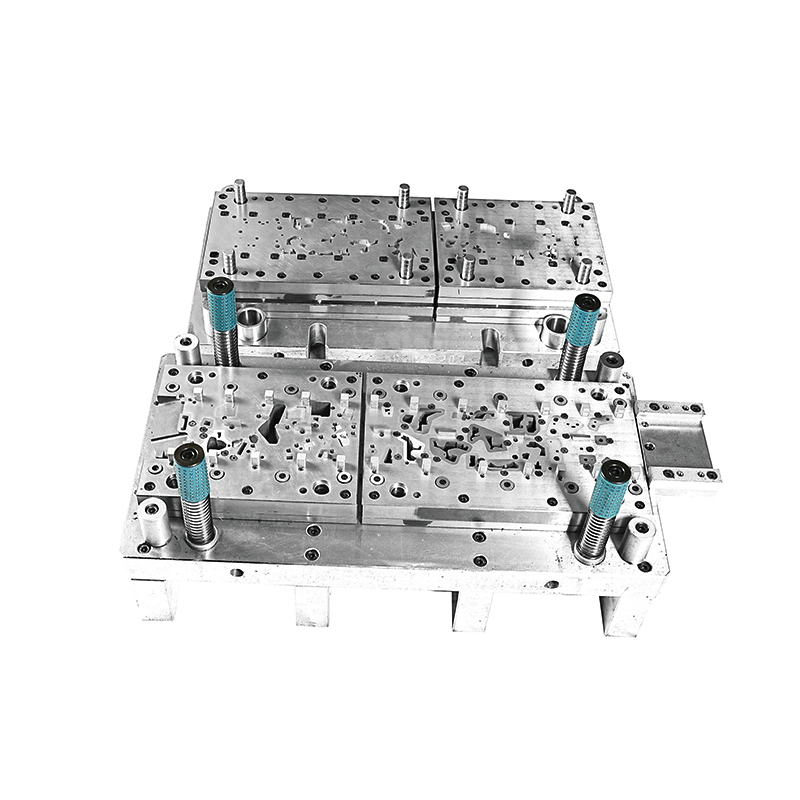

Manufacturing process: First, according to the design drawings of door lock parts, the selected metal sheet is cut into appropriate size and shape. This process is called blanking. Then, a series of stamping processes such as punching, stretching, bending, and forming are performed on the sheet through the stamping die to gradually process the sheet into the required component shape. For example, the lock body shell may need to undergo multiple stretching and bending processes to form a complex cavity structure; the lock tongue is stamped and then cut to ensure its dimensional accuracy and surface quality. During the stamping process, the accuracy of the mold and the stamping process parameters need to be strictly controlled to ensure the dimensional accuracy and consistency of the parts. After stamping, some parts may also need surface treatment such as electroplating, spraying, polishing, etc. to improve their corrosion resistance, wear resistance and aesthetics. Finally, after quality inspection, qualified door lock stamping parts are sent to the assembly workshop and assembled with other parts into a complete door lock product.

Applications

Common types include: lock body shell, lock tongue, transmission assembly, lock buckle, etc., mainly used in: family residences, commercial buildings, industrial sites, transportation fields, etc.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.