Description

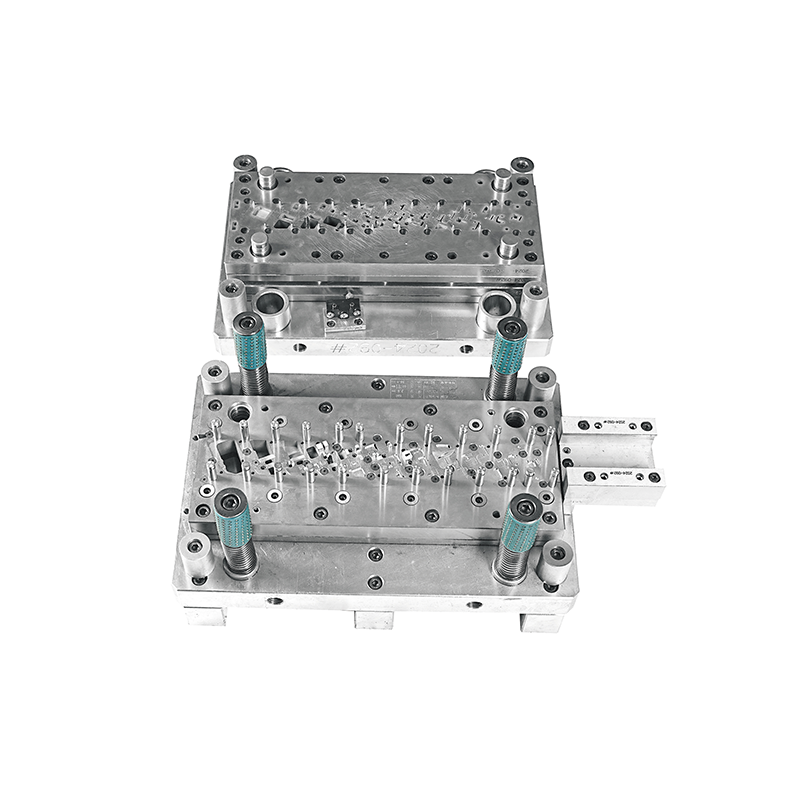

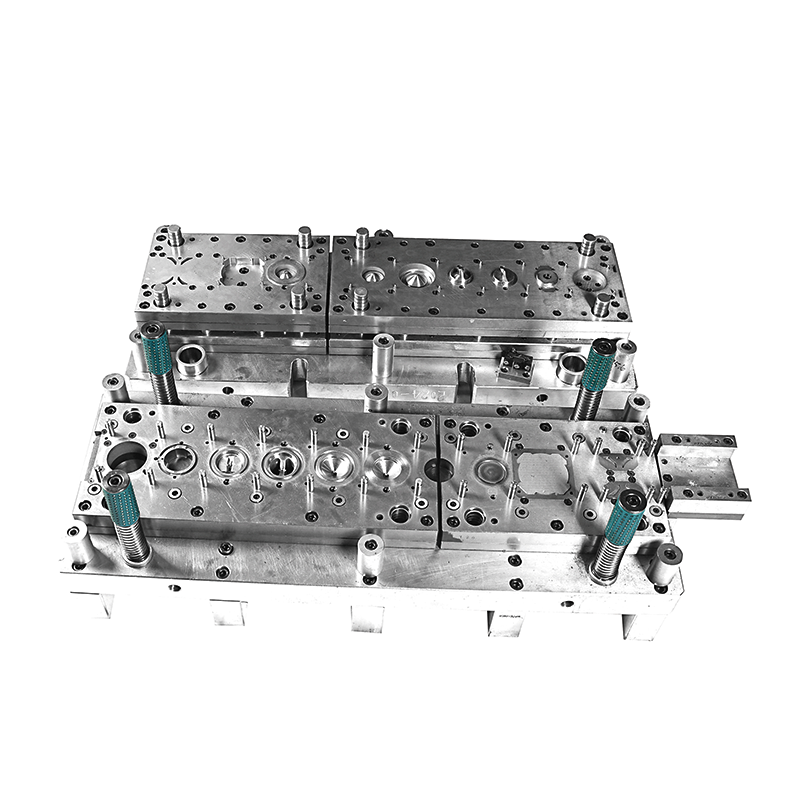

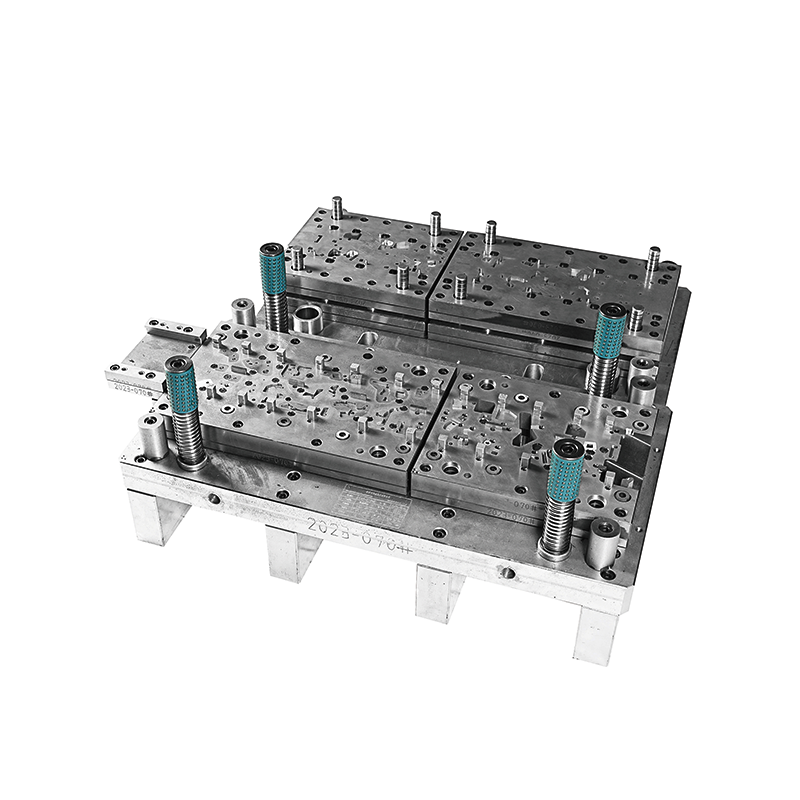

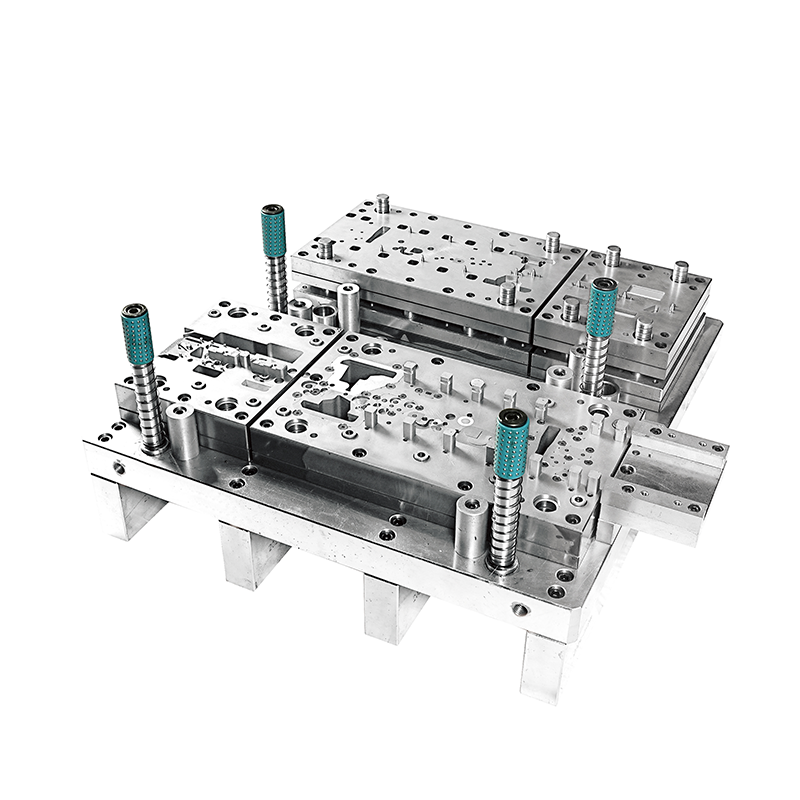

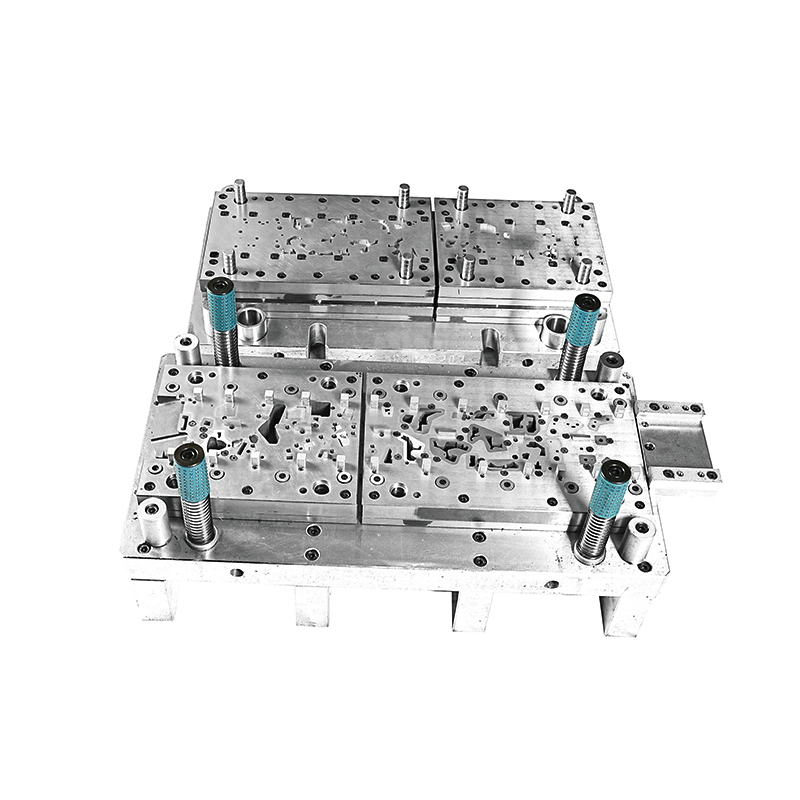

Elastic high-precision connector stamping die is a die used to manufacture high-precision elastic connectors.

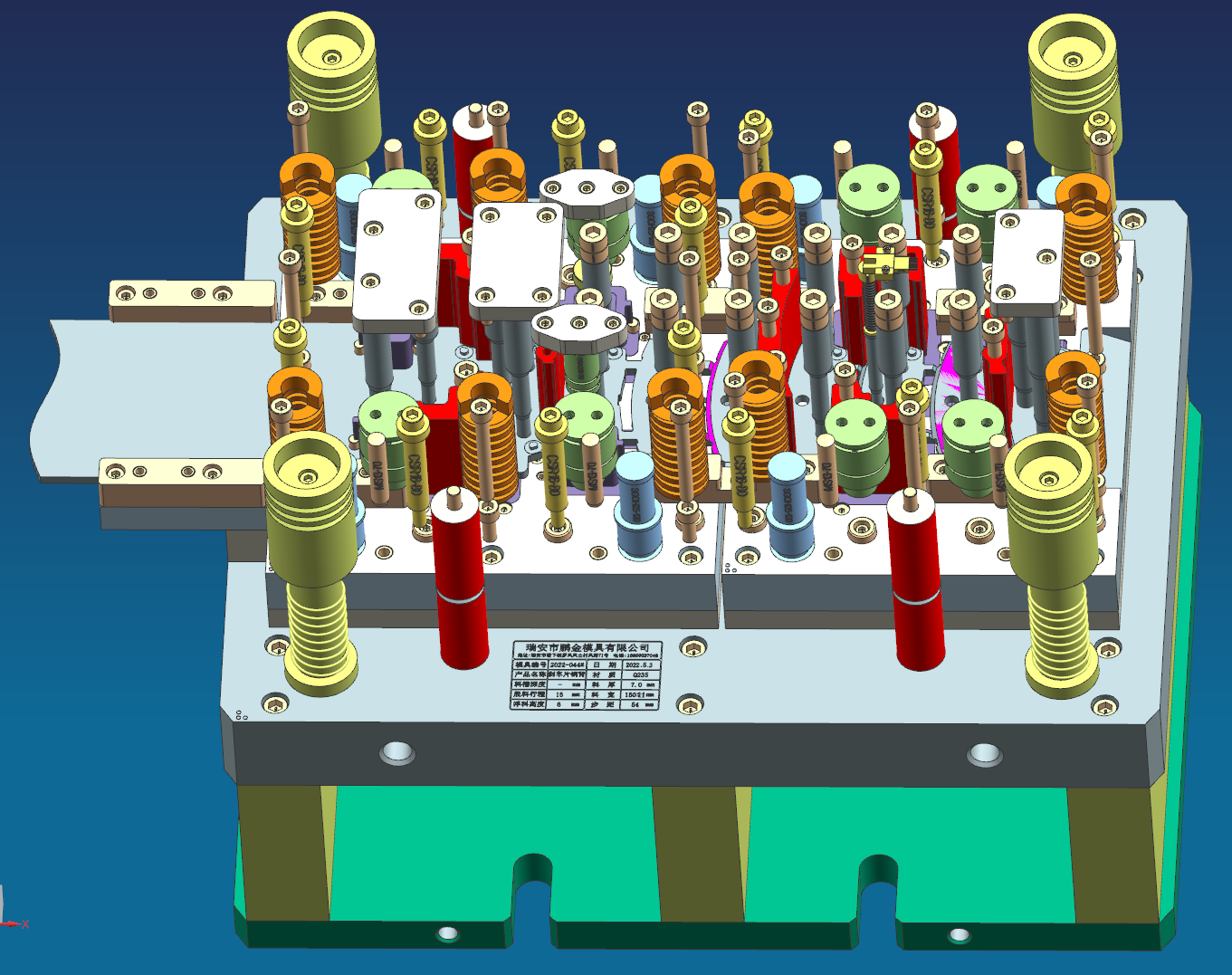

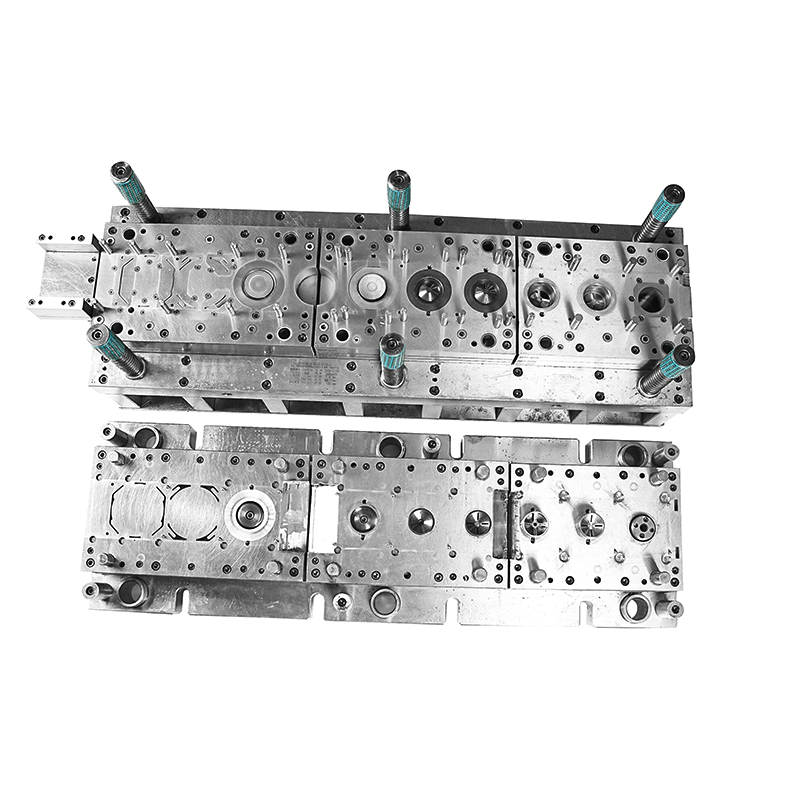

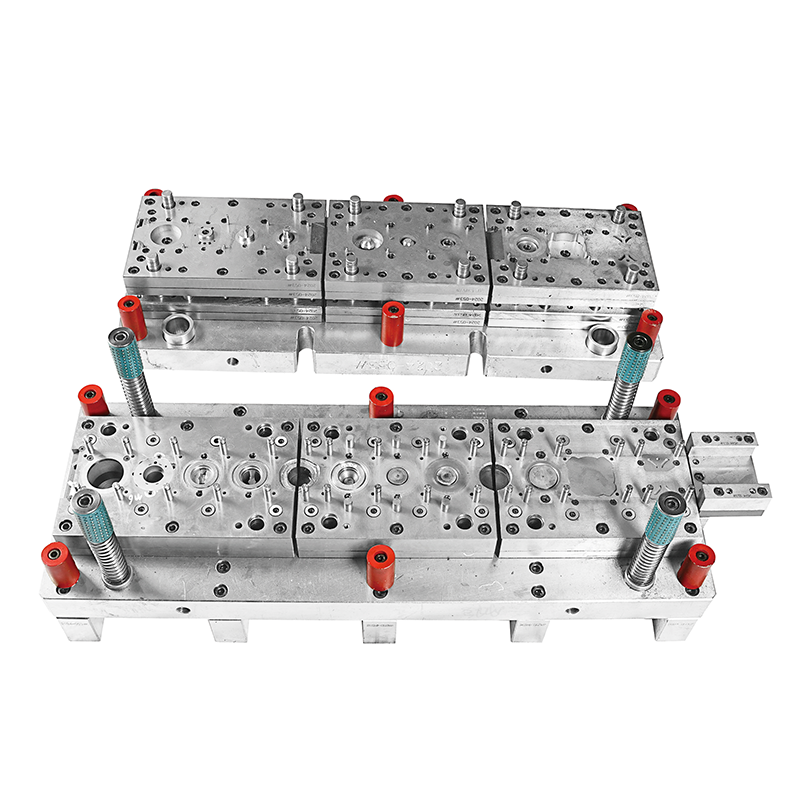

Mold structure: Similar to ordinary connector stamping dies, it consists of an upper die base, a lower die base, a punch, a die, a stripper plate, a guide mechanism, a positioning mechanism and a feeding mechanism. The difference is that elastic high-precision connector stamping dies usually design some special elastic elements, such as springs, elastic rubber pads, etc., to realize the elastic function of the connector. These elastic elements are generally installed at specific positions of the punch or die. Through reasonable design and layout, the stamped connector has suitable elastic properties.

Mold features

High precision: The dimensional tolerance of the connector can be controlled within a very small range, generally up to ±0.01mm or even higher accuracy, to ensure the precise matching of the connector with other electronic components. At the same time, the control of elastic properties is also very precise, ensuring that the elastic force and elastic deformation of each connector meet the design requirements.

Long life: Made of high-quality mold steel material, and after strict heat treatment and surface treatment processes, it has good wear resistance, fatigue resistance and corrosion resistance. In addition, the design and selection of elastic elements have also been carefully considered, which can maintain stable elastic properties in mass production and extend the service life of the mold.

Strong ability to process complex shapes: Through the reasonable design of multiple stations and special stamping processes, the processing of complex-shaped elastic connectors can be achieved to meet the diverse needs of different electronic equipment docking connectors. For example, connectors with multiple bending angles, different elastic arm lengths and shapes can be manufactured.

Applications

Mainly used in industries such as electronics, automobiles, and communications that require extremely high precision and reliability of docking plug-ins. In electronic equipment, it is often used to manufacture various circuit board connectors, headphone sockets, USB interfaces, etc. In the automotive field, it can be used to produce connectors and sensor connectors in automotive electronic systems; in communication equipment, it can be used to manufacture optical fiber connectors, radio frequency connectors, etc.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.