Description

Electrical panel stamping parts refer to various parts used in electrical equipment panels manufactured by stamping process.

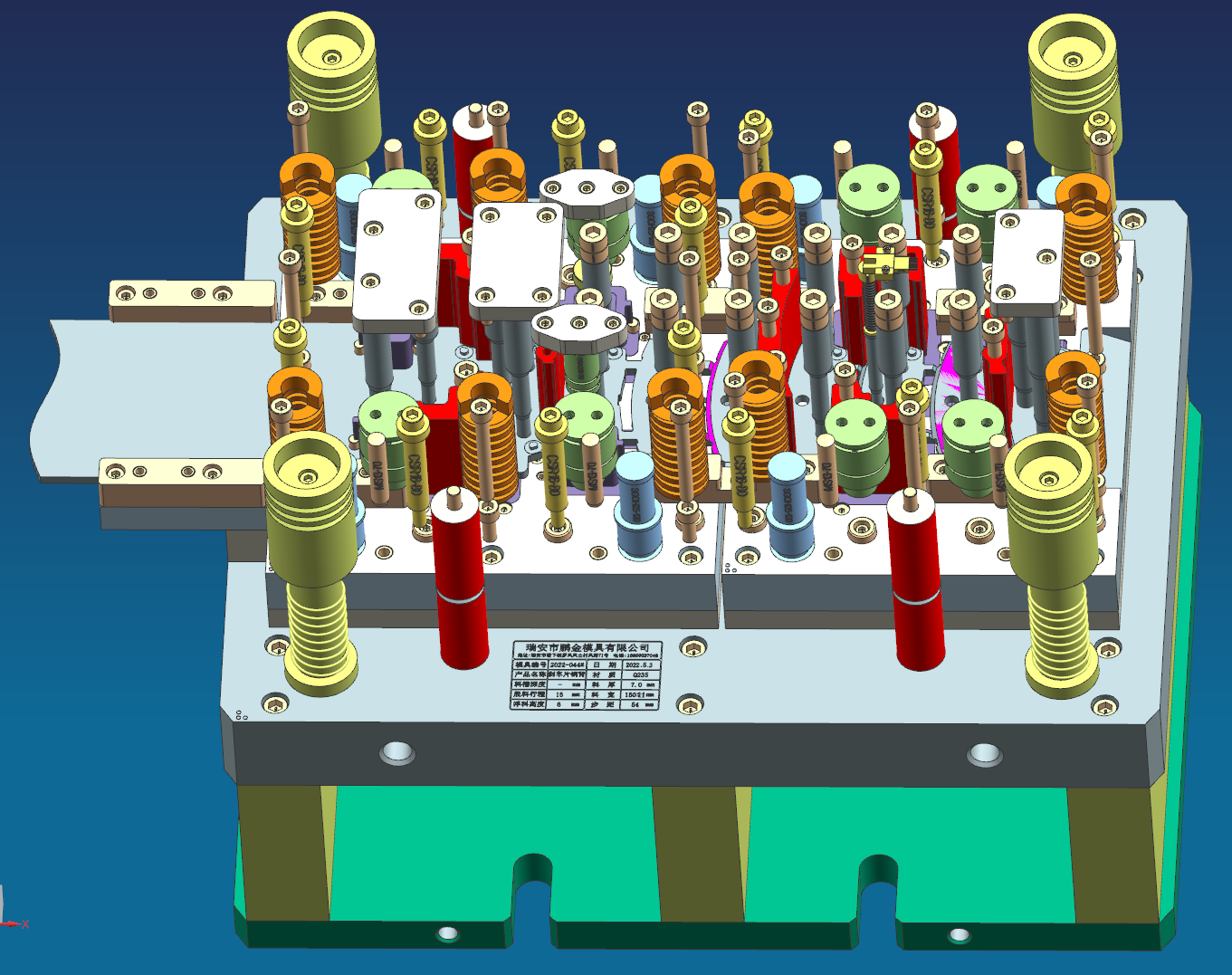

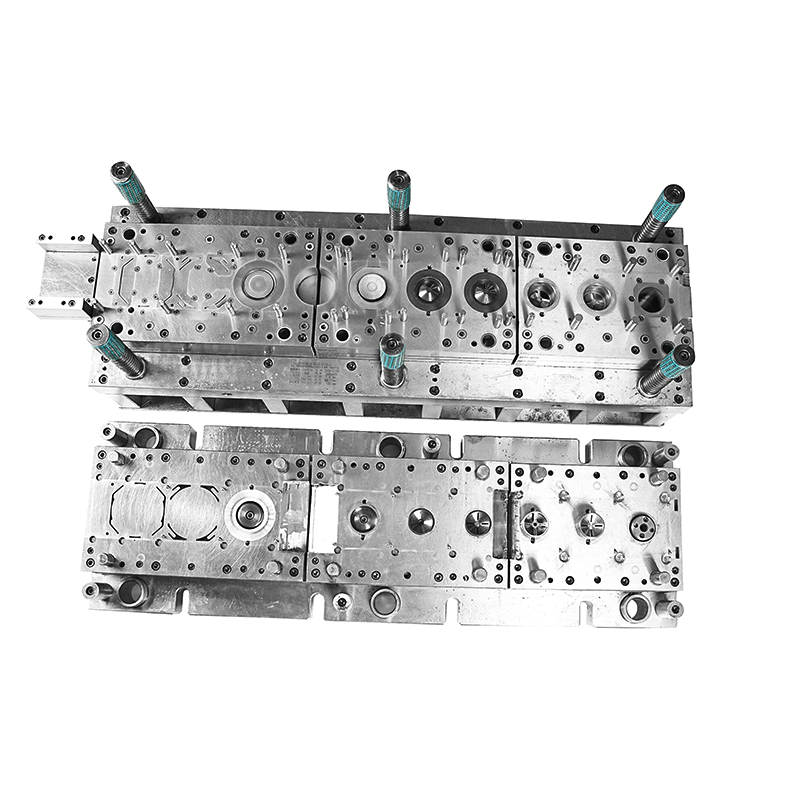

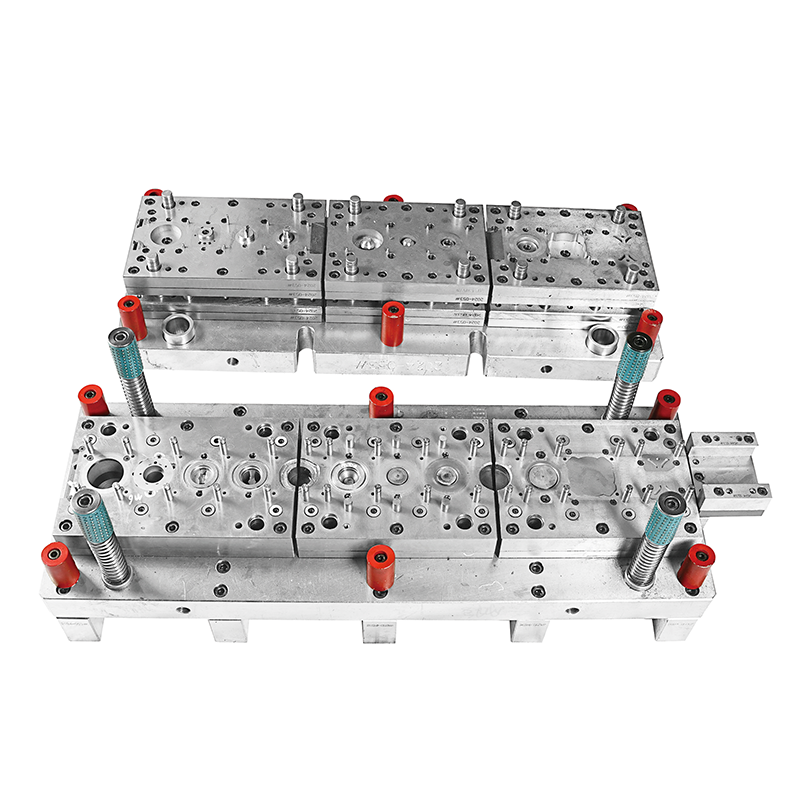

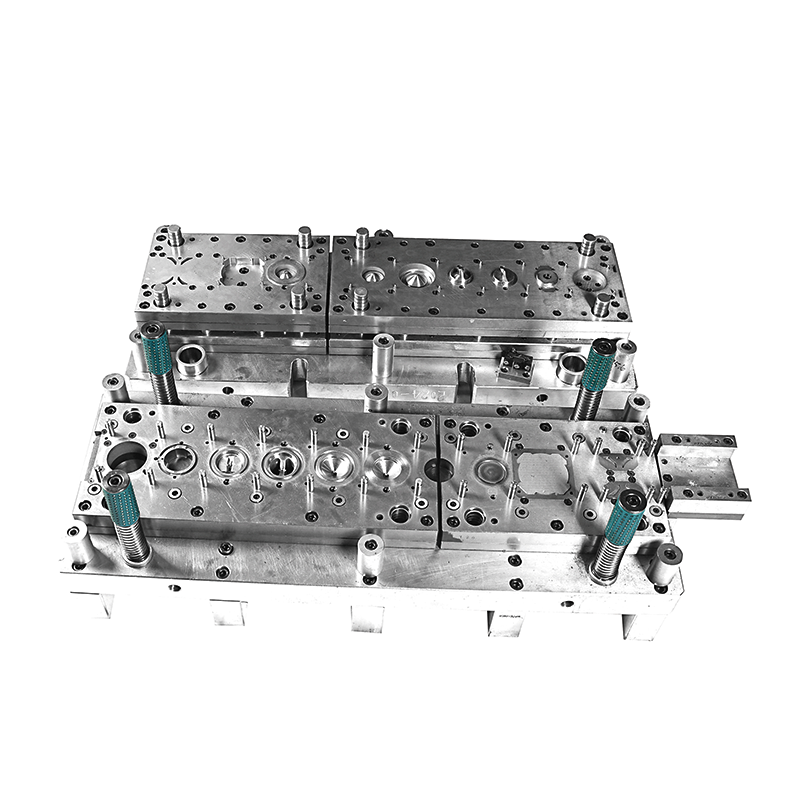

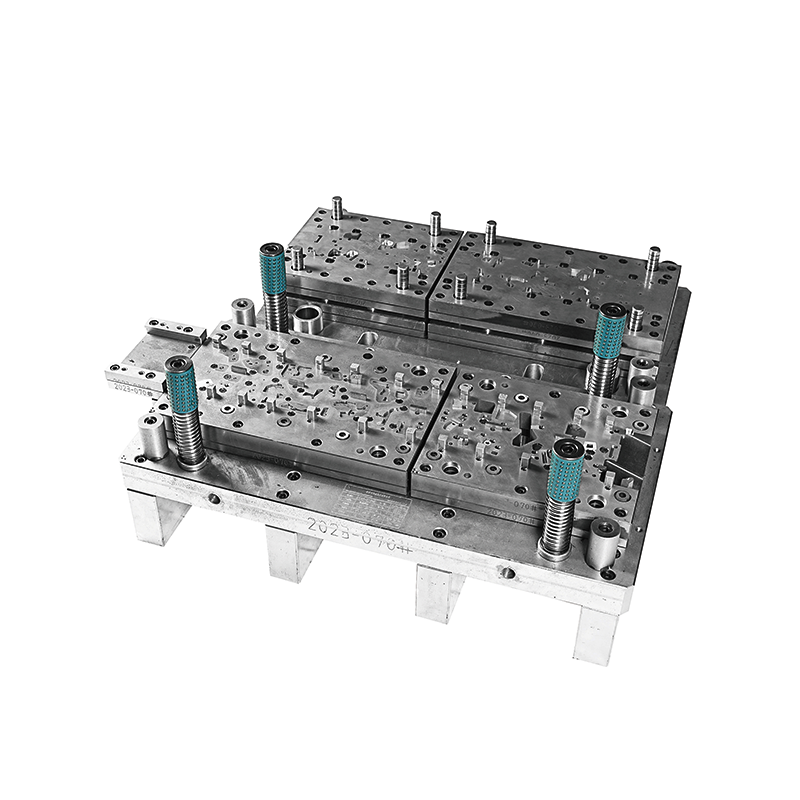

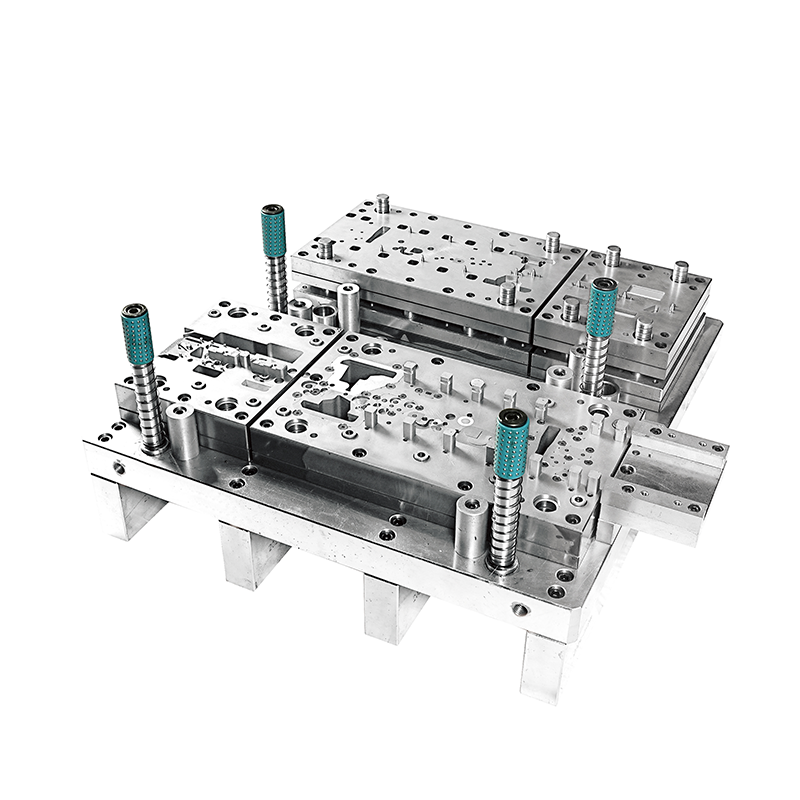

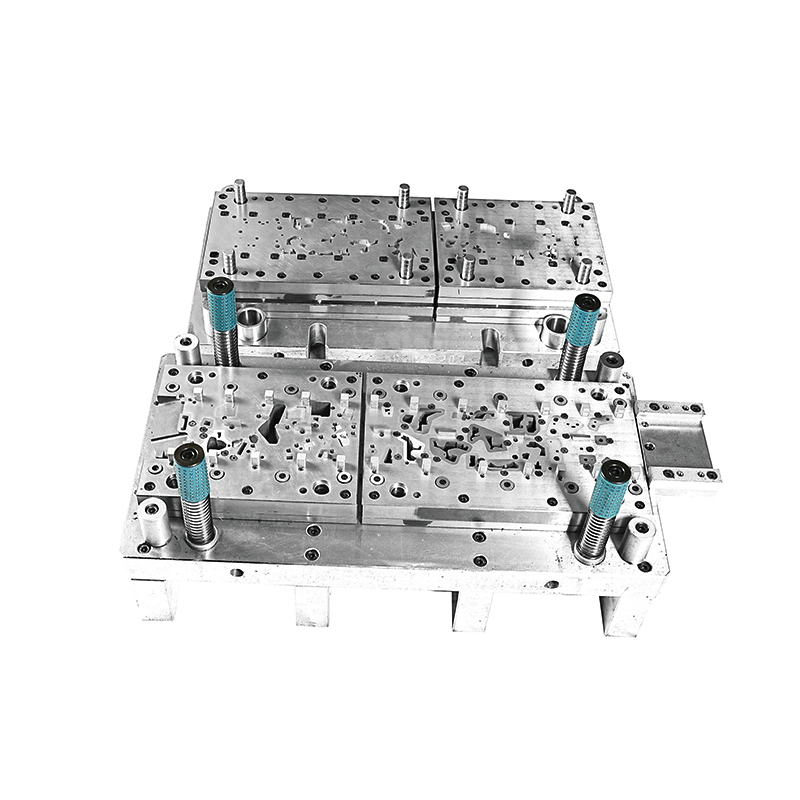

Manufacturing process: Stamping is a processing method that uses equipment such as punching machines to apply pressure to the sheet through a mold to cause plastic deformation or separation, thereby obtaining parts of the required shape and size. This process has the advantages of high efficiency, high precision, low cost, etc., and can achieve mass production.

Common materials: Generally, metal sheets with good stamping properties, such as cold-rolled steel sheets, galvanized steel sheets, etc., are used to ensure the quality and performance of parts. For some high-end electrical appliances or electrical panels with special requirements, stainless steel plates, aluminum plates and other materials may also be used.

Function: Electrical panel stamping parts are an important part of the appearance and function of electrical products. They constitute the operating panel of electrical equipment, which usually has various switch holes, indicator light holes, display screen installation positions, etc., which are used to install and fix the operating parts and display parts of the electrical appliances, so that users can operate and view the working status of the electrical appliances. At the same time, these parts also play a role in protecting the internal components of the electrical appliances, have a certain strength and stability, and can resist external collisions and wear.

Applications

It is widely used in various electrical products, such as air conditioners, refrigerators, washing machines, microwave ovens and other household appliances, as well as industrial control electrical appliances and other equipment.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.