Description

Lighting housing stretching parts are parts and components used to form the housing of lighting equipment manufactured through a stretching process

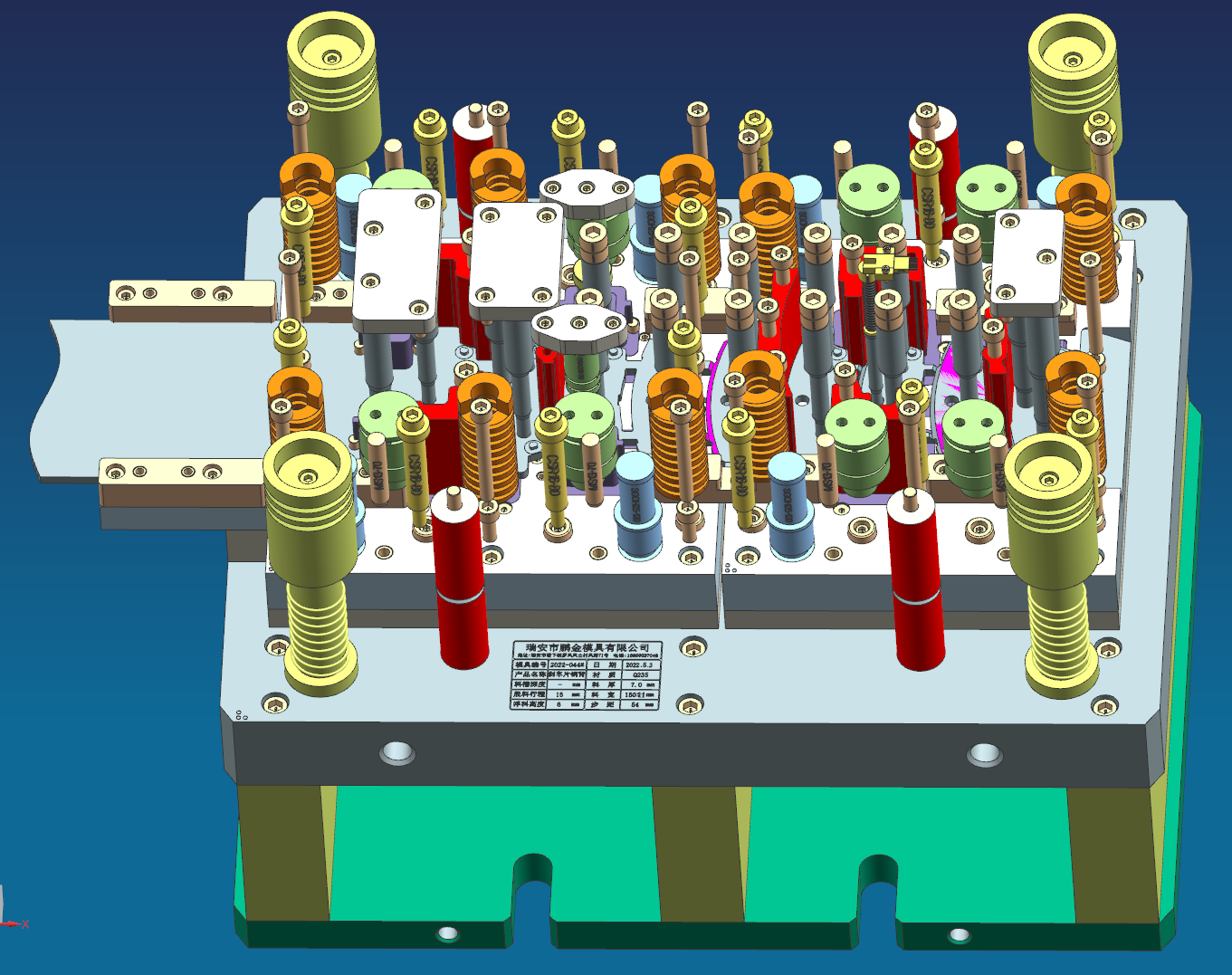

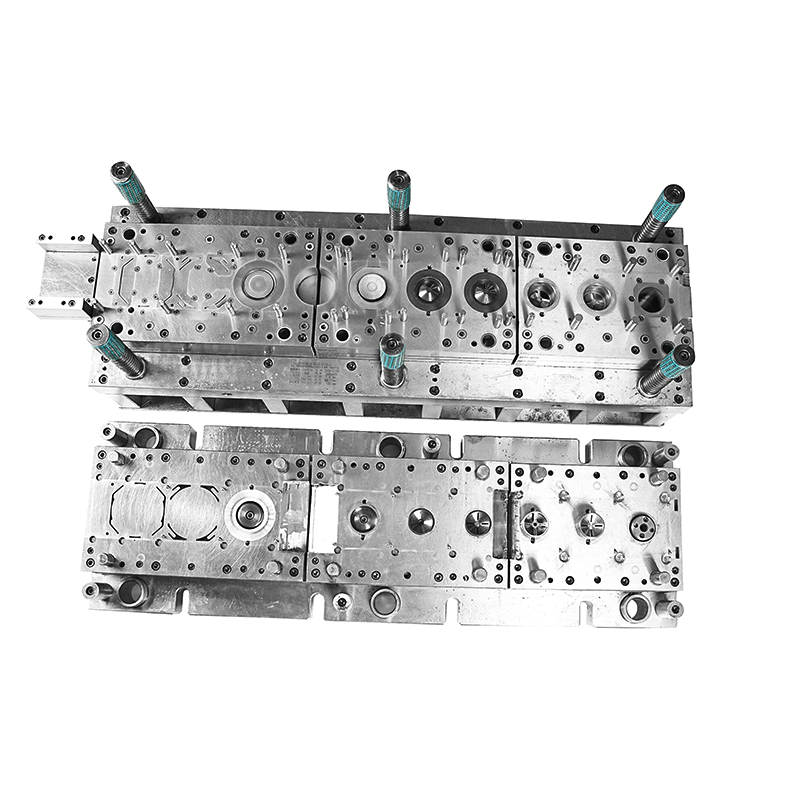

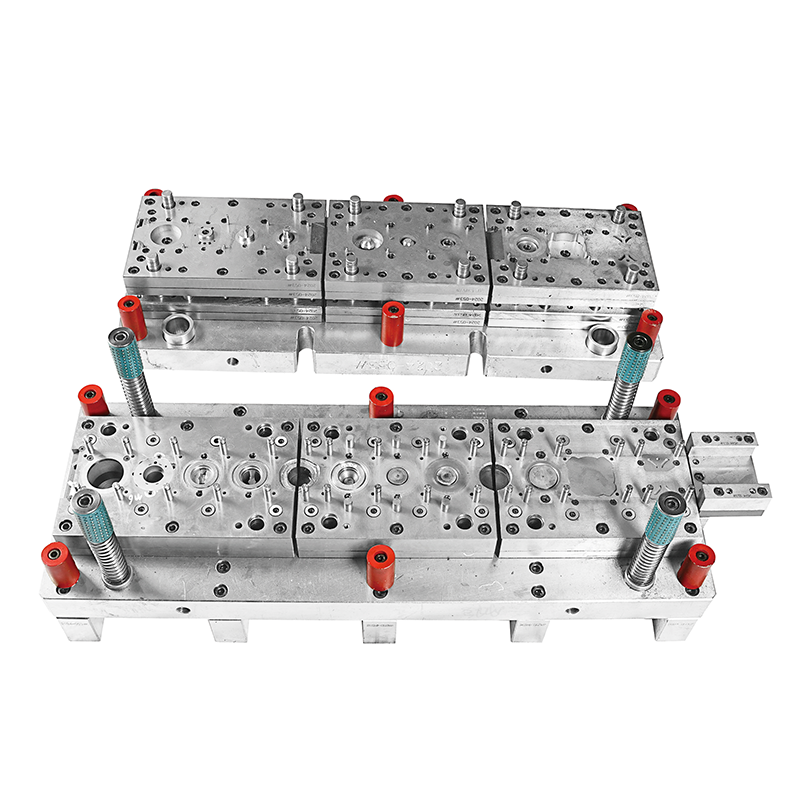

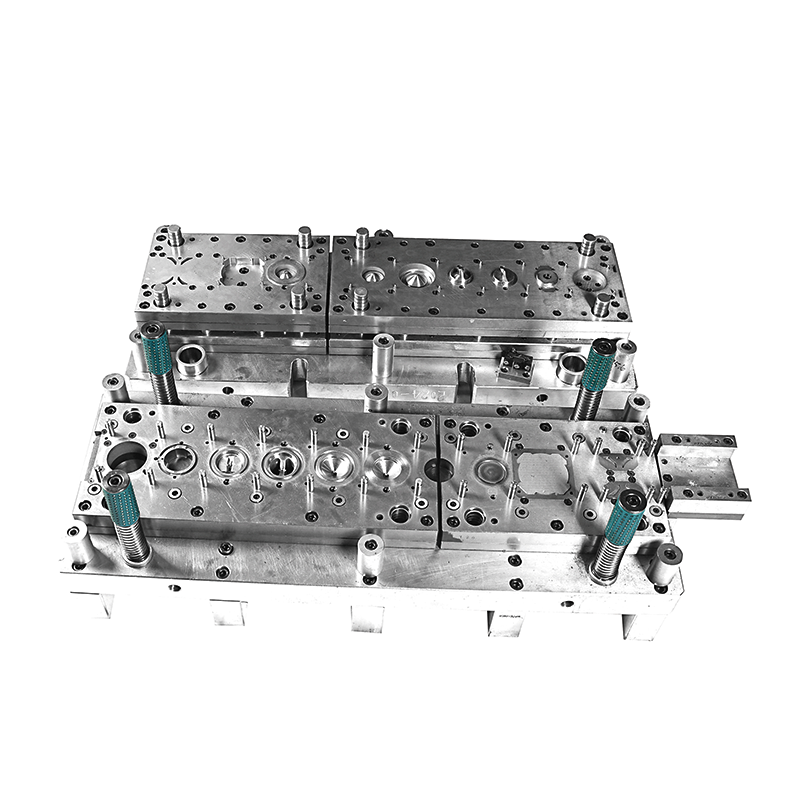

Manufacturing process: The manufacturing of lighting housing stretching parts generally involves cutting the metal sheet into a suitable size and shape first, and then placing it in a stretching die. Under the action of the stretching equipment, the die applies a uniform tensile force to the sheet, causing the sheet to gradually deform along the shape of the die to form a lighting housing part with a specific curvature and depth, such as a lampshade, lamp holder housing, etc. During the stretching process, the strength, speed, and number of stretching need to be precisely controlled to ensure the dimensional accuracy and surface quality of the parts, and to prevent problems such as rupture caused by excessive stretching or shape failure caused by insufficient stretching. For some lighting housing parts with complex shapes, multiple stretching and subsequent auxiliary processes such as trimming, punching, and flanging may be required to complete the final processing.

Commonly used materials: Commonly used materials include aluminum alloy, which has the advantages of light weight, corrosion resistance, and good thermal conductivity. It can effectively reduce the weight of lamps and help dissipate heat, and is suitable for various indoor and outdoor lighting fixtures; stainless steel is also one of the common materials, such as 304 stainless steel, which has good corrosion resistance and strength, can make the lighting shell have good durability and stability, and is often used in lighting equipment with high requirements for environmental adaptability; in addition, some plastic materials such as polycarbonate (PC) are also used to manufacture lighting shell stretch parts. PC materials have high transparency, good impact resistance and insulation properties, which can meet the requirements of different lighting fixtures for light transmittance and safety.

Function: Lighting shell stretch parts are an important part of lighting equipment. They are mainly used to protect the light source, circuit and other components inside the lighting fixture from external environmental factors, such as dust, water vapor, rain, etc., and provide structural support for the lamp to ensure the overall stability of the lamp. Different types of lighting shell stretch parts can be shaped into various beautiful shapes according to the design requirements of the lamp, which play a role in decoration and beautification of the environment, and meet the lighting and aesthetic needs of different places.

Applications

Widely used in various lighting equipment such as chandeliers, ceiling lamps, wall lamps for indoor lighting, and street lamps, landscape lamps, and floodlights for outdoor lighting.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

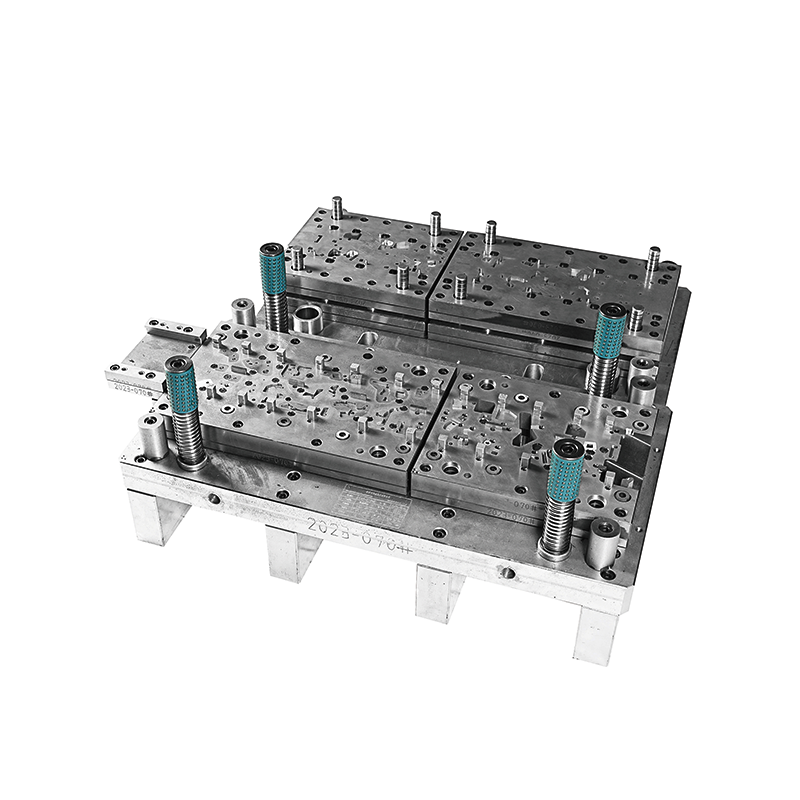

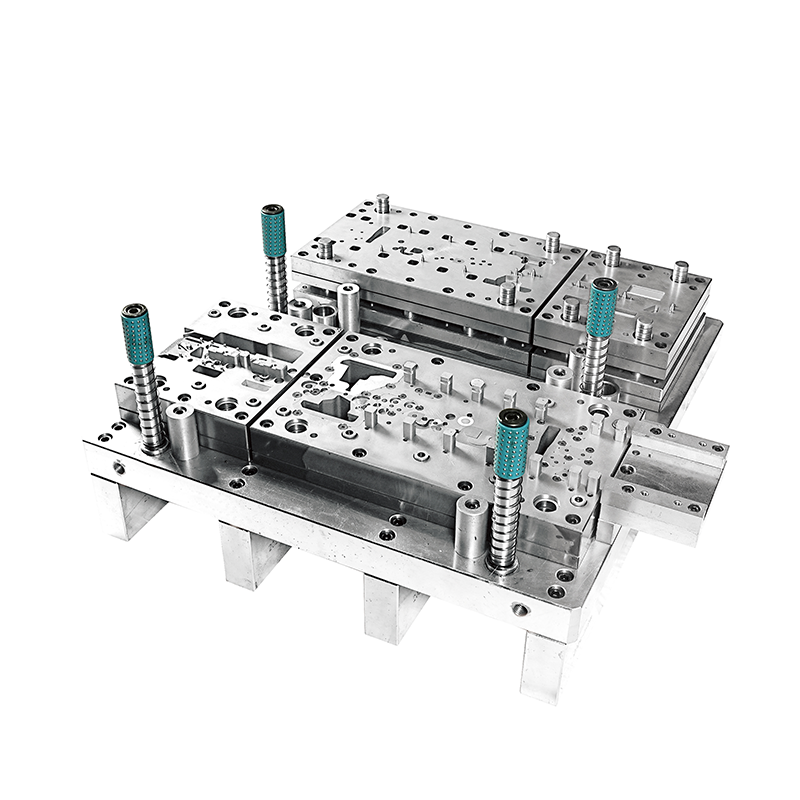

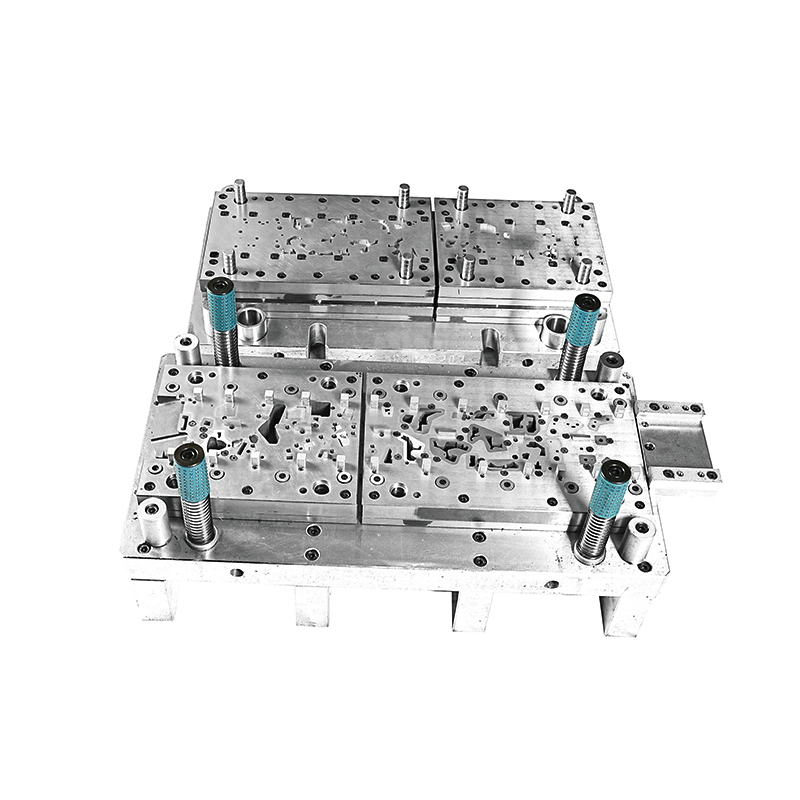

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.