Description

Stamping parts for electrical boxes are manufactured through stamping processes and are used to form various parts of electrical boxes. They play an important role in protection, support and wiring management in electrical equipment.

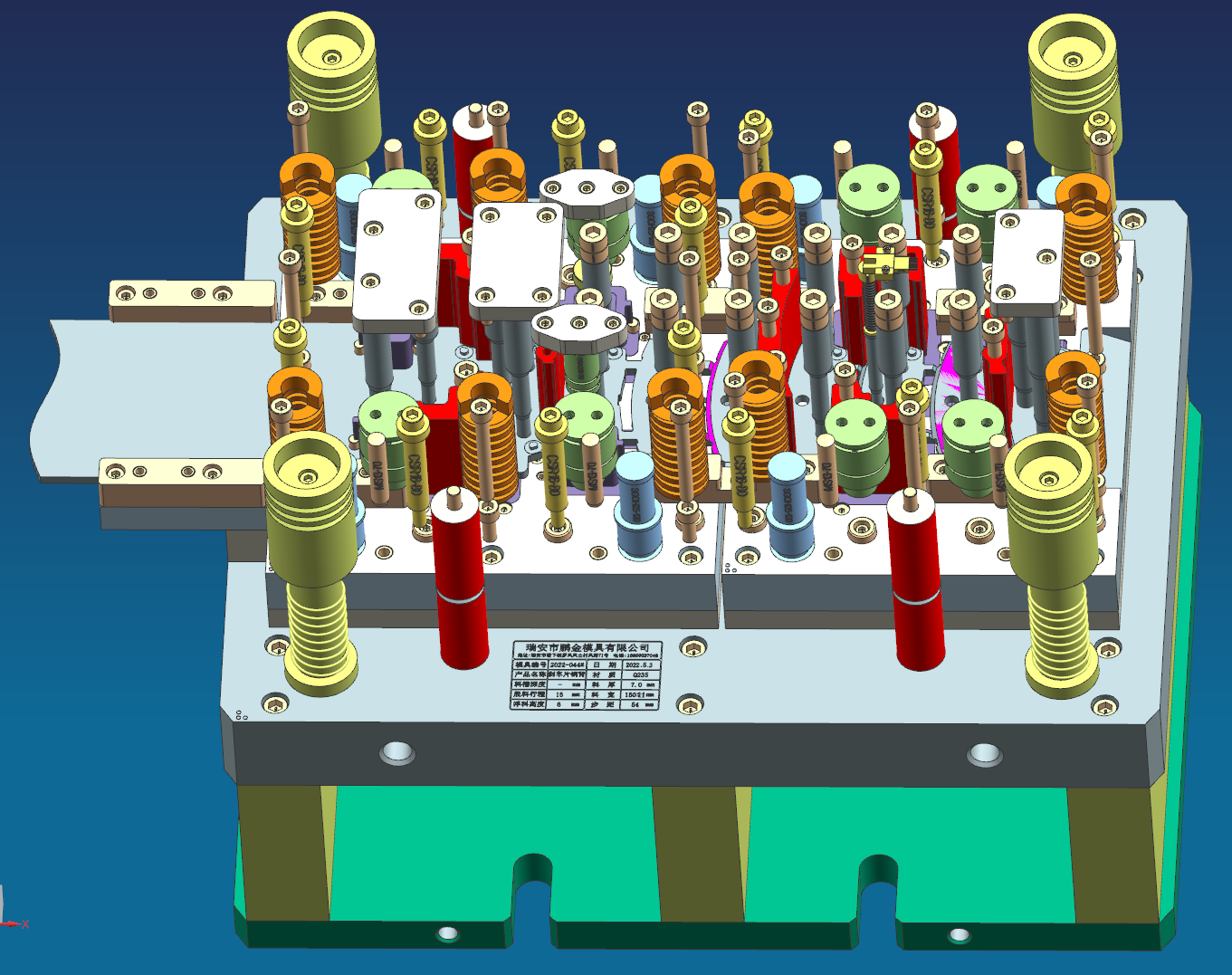

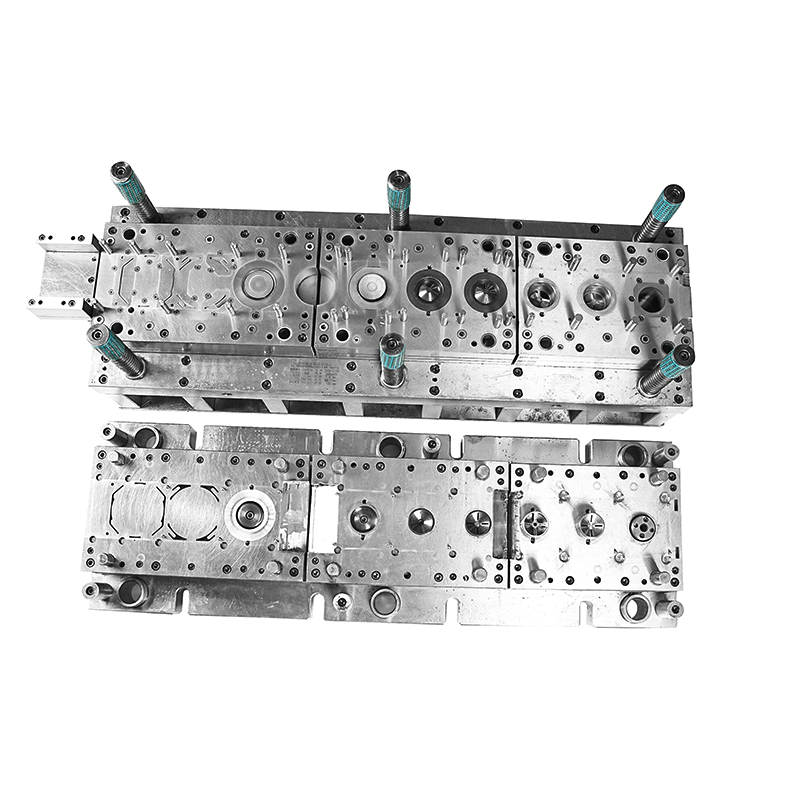

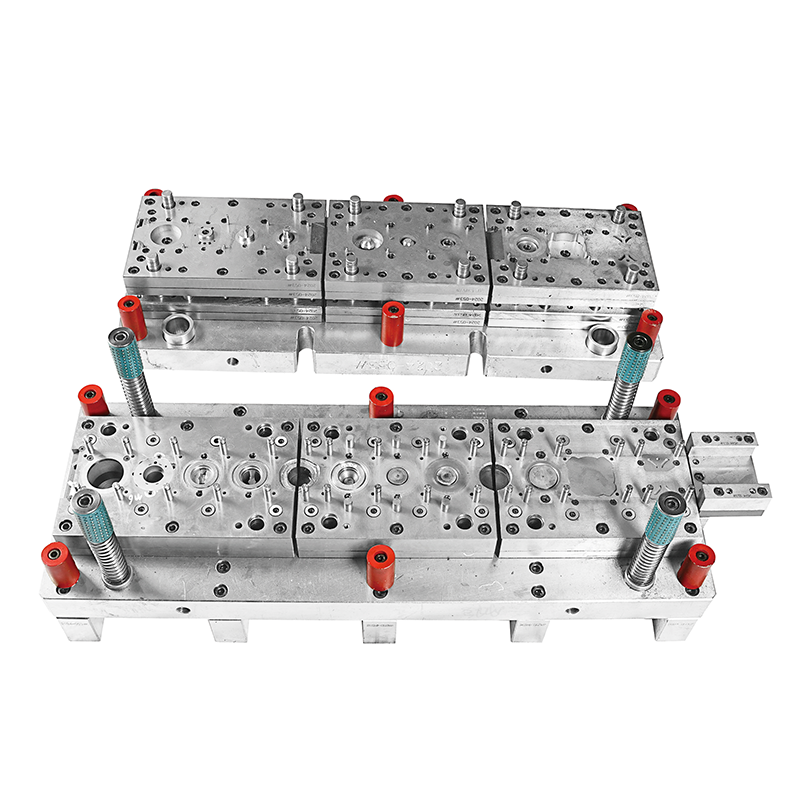

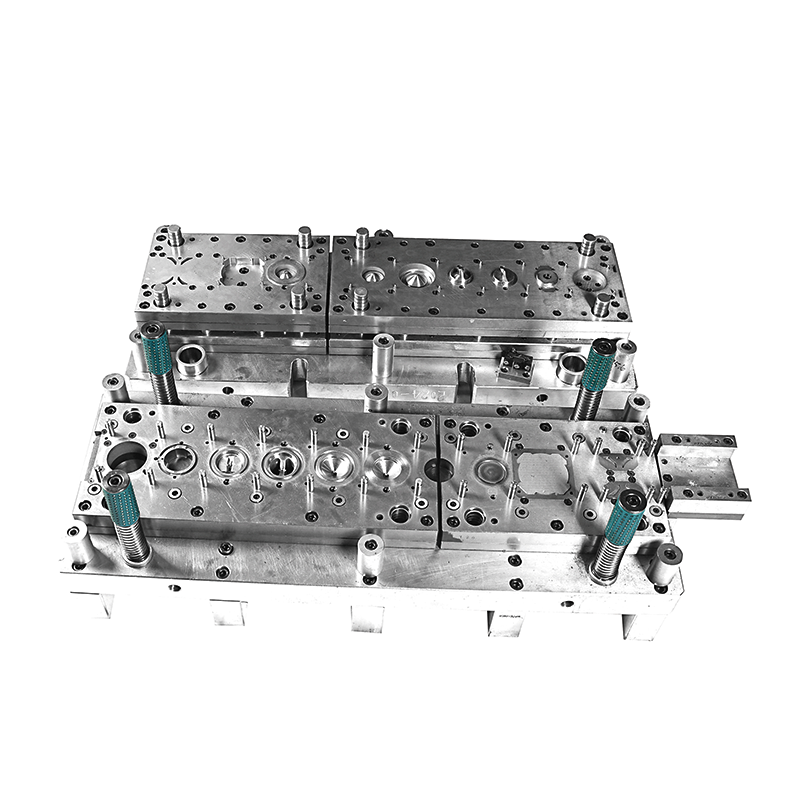

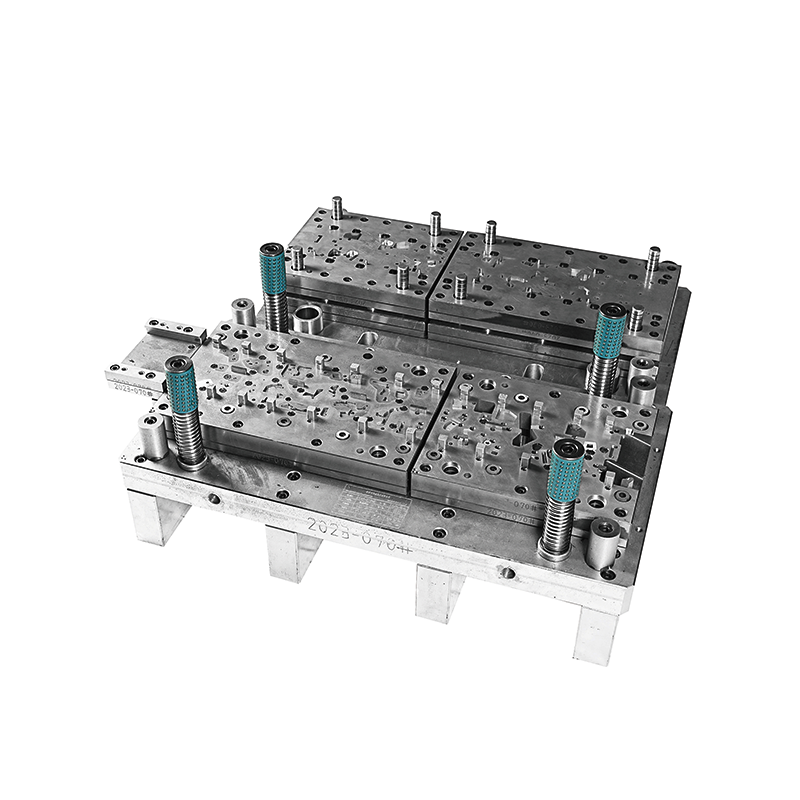

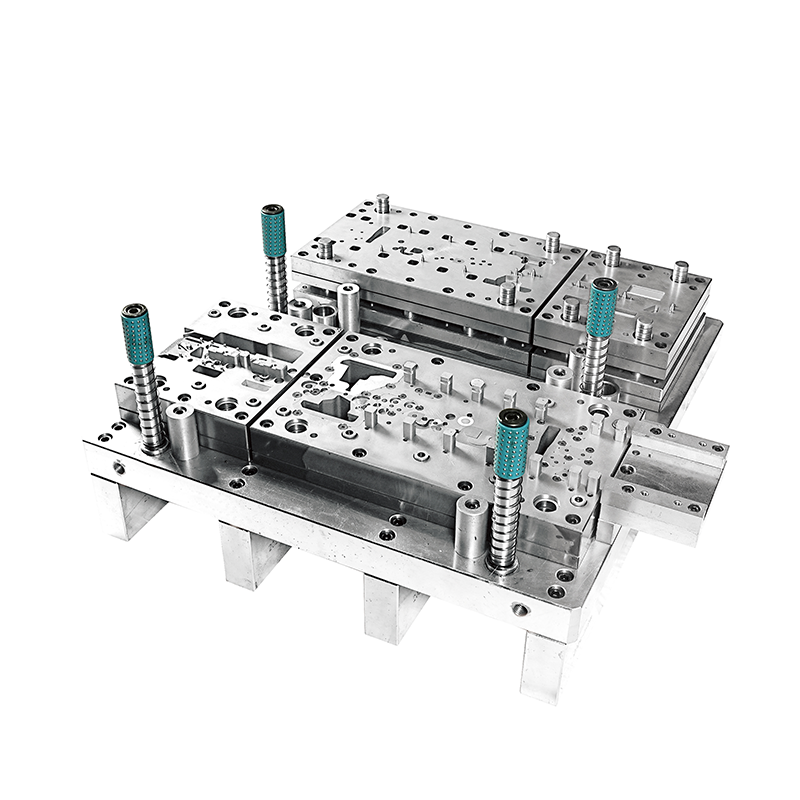

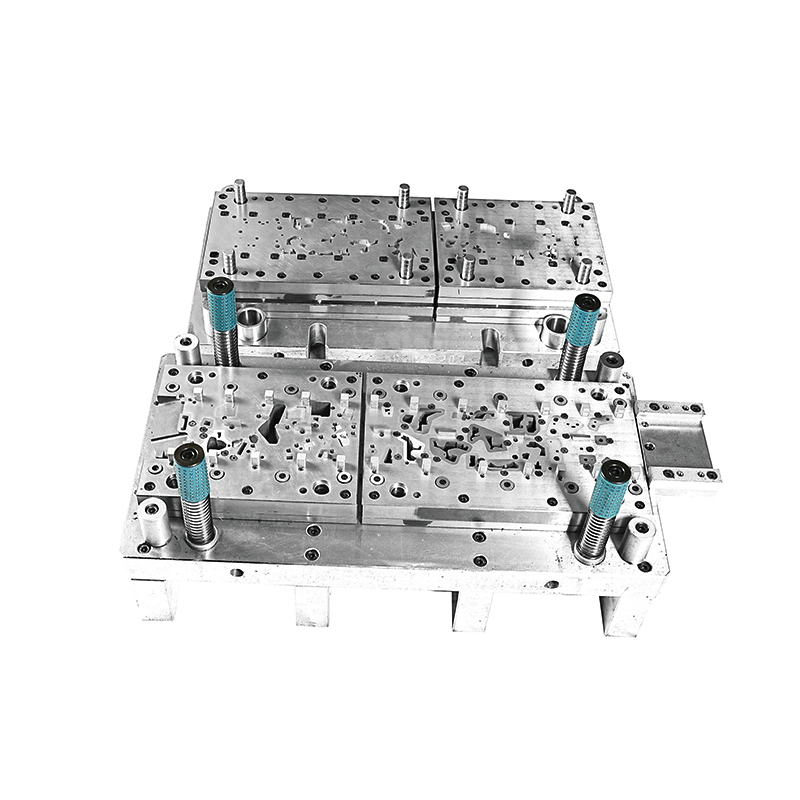

Manufacturing process: Use stamping equipment, such as punching machines, to process metal sheets with specific molds. First, cut the metal sheet to the appropriate size, and then accurately shape various shapes of parts, such as the box body, door, mounting plate, and reinforcement ribs of the electrical box through a series of stamping processes such as punching, blanking, bending, and stretching. To ensure quality and precision, some parts with complex shapes may require multi-step stamping, and some parts may also require subsequent processing, such as deburring and surface treatment.

Common materials: Mainly use metal sheets with certain strength, hardness and corrosion resistance. Common ones are cold-rolled steel sheets, which have good processing performance and cost advantages and can meet the use requirements of general electrical boxes; for some electrical boxes used outdoors or with high corrosion resistance requirements, galvanized steel sheets or stainless steel sheets will be used to enhance the corrosion resistance of the electrical box and extend its service life.

Function : Stamping parts of electrical boxes are the key parts of electrical boxes. The box body and door provide a closed space for electrical equipment, which can protect the internal electrical components from external environmental factors, such as dust, water vapor, external force impact, etc.; the mounting plate is used to fix various electrical components, such as circuit breakers, contactors, relays, etc., so that they can be reasonably laid out according to design requirements, which is convenient for electrical connection and line layout; the reinforcing ribs can enhance the structural strength of the electrical box, prevent the box body from deformation during use, and improve the overall stability.

Applications

Widely used in various electrical box equipment such as distribution cabinets and control cabinets in the industrial field, and distribution boxes in the civil field.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.