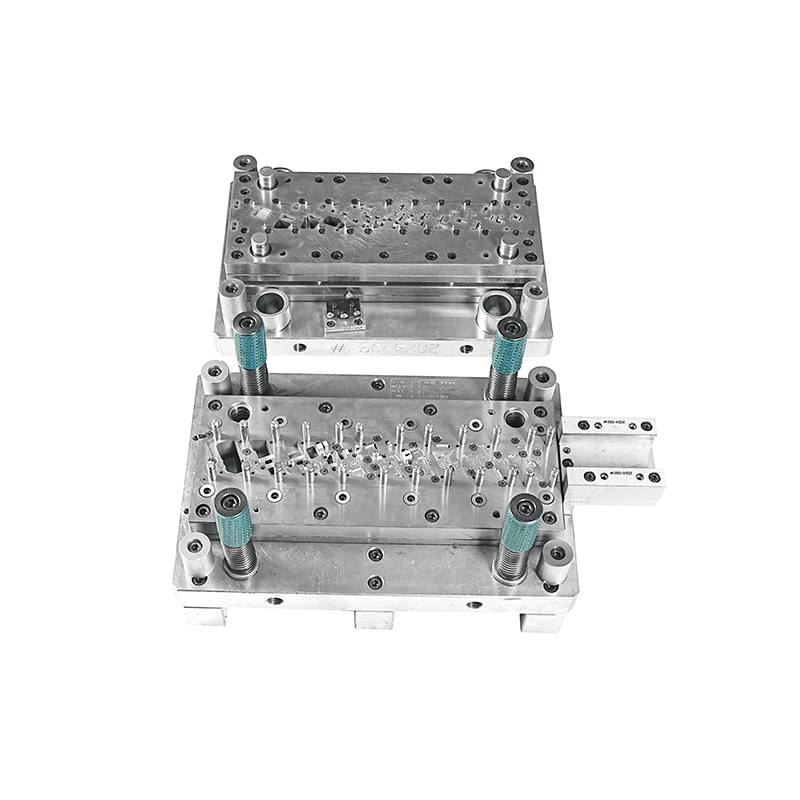

Embossing Metal Stamping Die for Decorative and Functional Surfaces

The new embossing metal stamping die that we provide is the best thing so that the surface of the sheet metal part is made attractive and identification and information about it are more visible and detailed. The die is used to manufacture of various products, such as brandplates, control panels, metal signs, and housings of appliances. It works by using the fine engraved tool steel plates so it is simple to have the drawings with details impressed or deeper into the material without any technical issues in measurement. The necessary time for the accomplishment of the projects can be saved by our competent workforce(team) while working on other efficiency-improving methods.

Grads of power and the moon grip design are some of the outstanding features in which this die interfaces. This method demands less scrapping and the entire clean, exact and distortion-free material process is now achievable. This die will allow you to emboss aluminum, brass, and stainless steel and thus be able to transform light metal into a product that will be of high utility and at the same time be appealing in appearance.

Copyright © Pengjin Mold | Privacy policy