Description

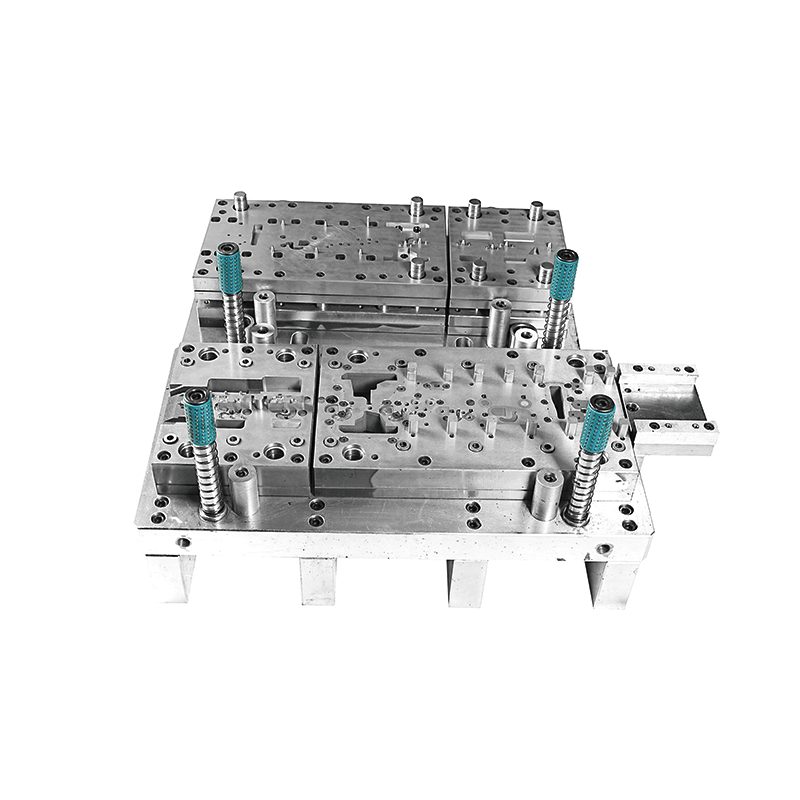

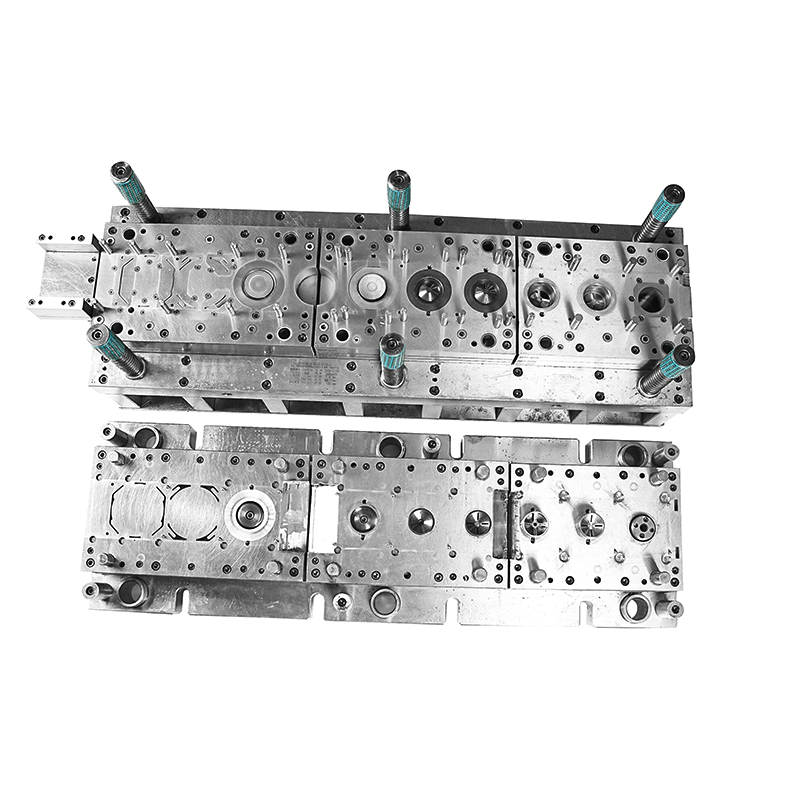

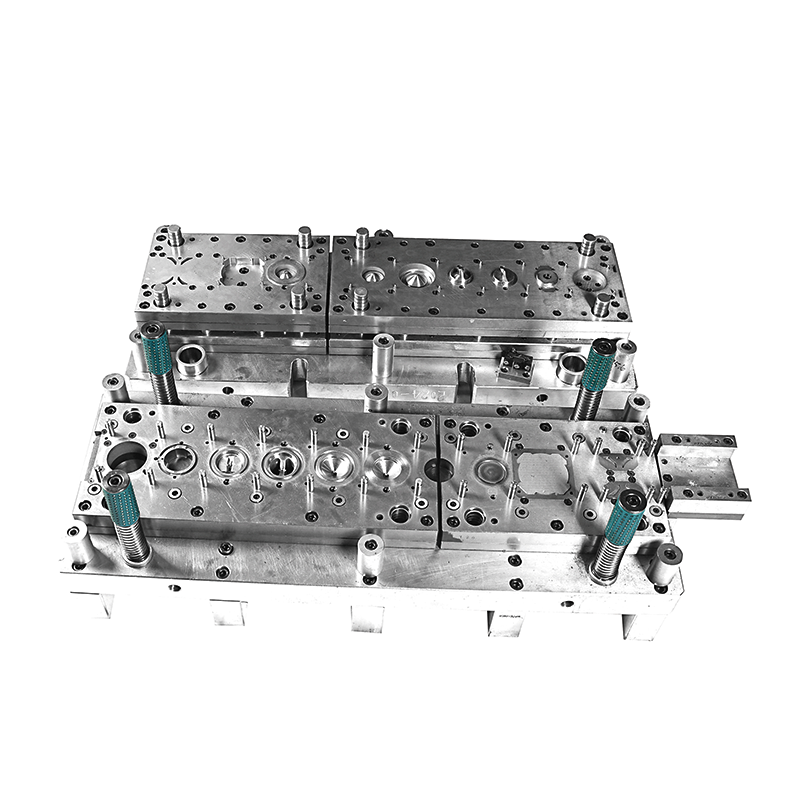

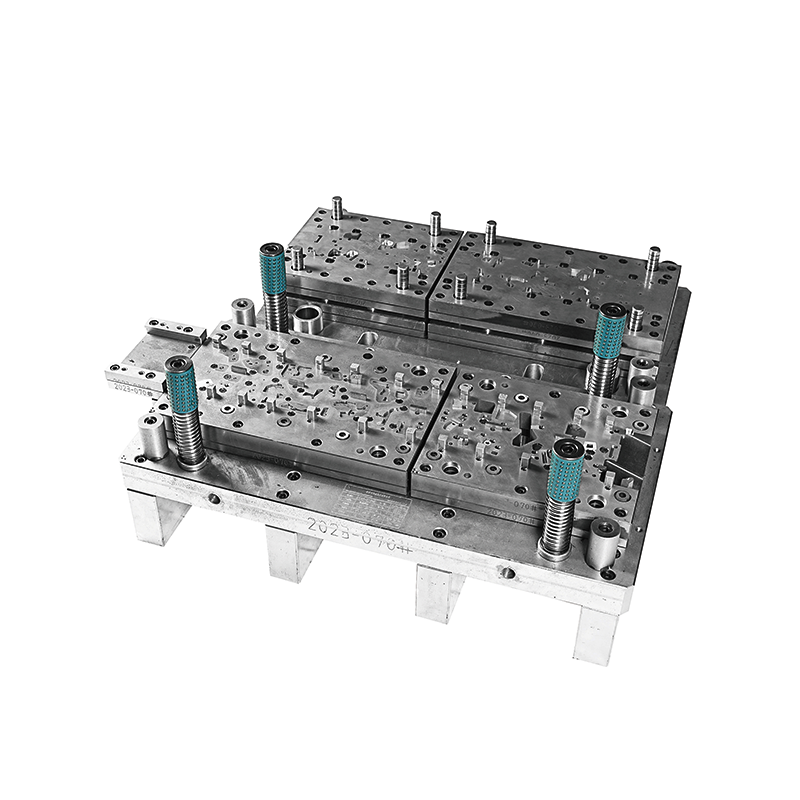

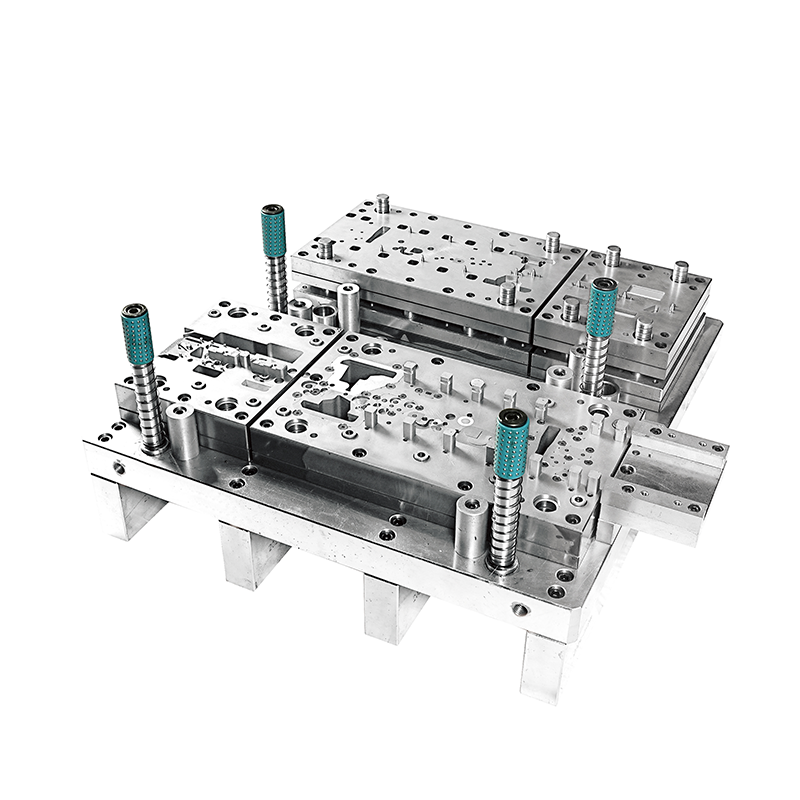

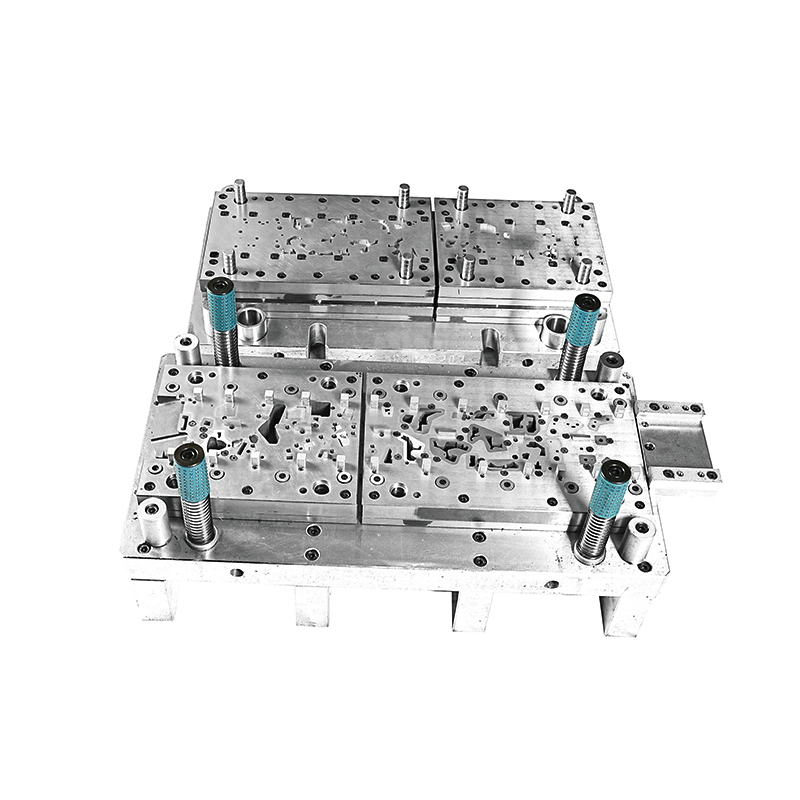

High-precision connector continuous stamping die is an advanced die used for the production of precision connectors, with the characteristics of high precision and high efficiency.

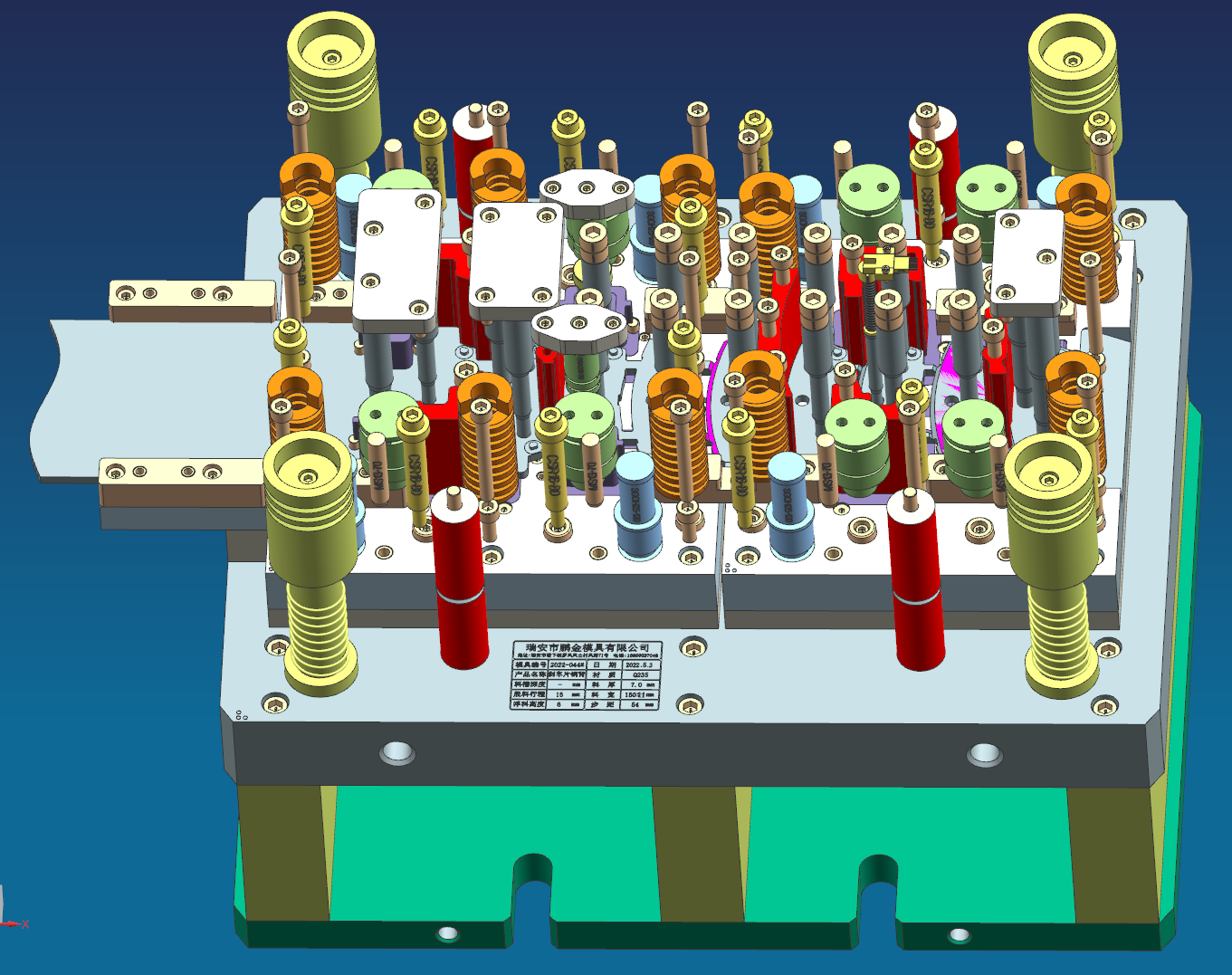

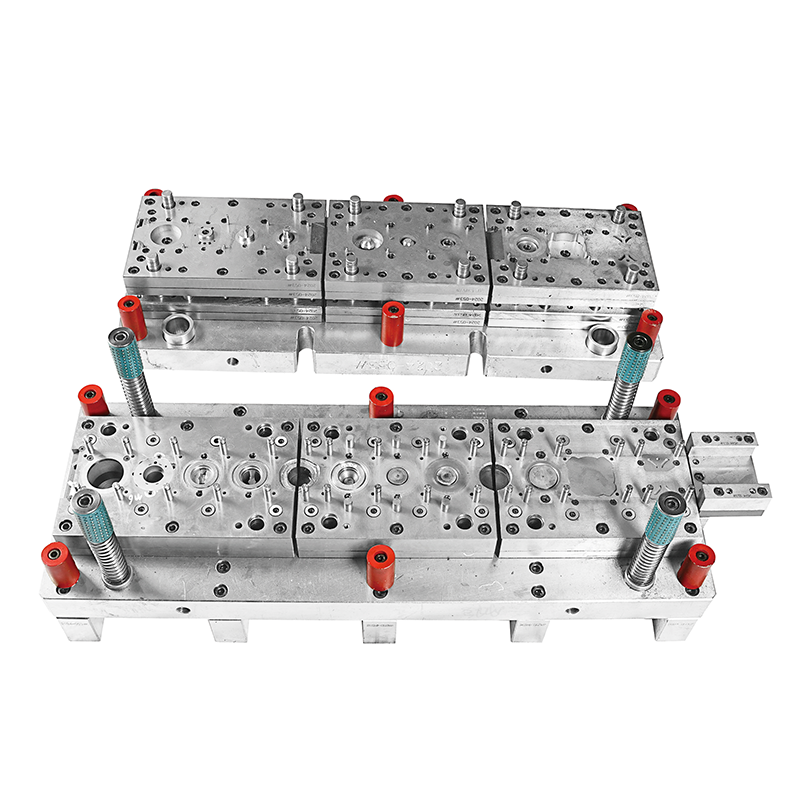

Mold structure: usually composed of upper die seat, lower die seat, punch, die, unloading plate, guide mechanism, positioning mechanism and feeding mechanism. The upper and lower die seats play a supporting role; the punch and die are key molding components, and the size and shape are precisely designed according to the connector, with extremely high processing accuracy. The guide mechanism ensures the precise guidance of the upper and lower dies, the positioning mechanism ensures the accurate position of the blank, the unloading plate is used for unloading after stamping, and the feeding mechanism realizes the automatic and precise feeding of the blank.

Mold features

High precision: The dimensional tolerance of the connector can be controlled within a very small range, generally up to ±0.01mm or even higher accuracy, to ensure the precise matching of the connector with other electronic components.

High efficiency: The continuous stamping method, combined with the automatic feeding and unloading mechanism, can achieve high-speed and continuous production, greatly improve production efficiency and reduce costs.

Long life: Select high-quality mold materials, undergo strict heat treatment and surface treatment, have good wear resistance, fatigue resistance and corrosion resistance, can maintain stable performance in mass production and extend service life.

Strong ability to process complex shapes: Through the reasonable design of multiple stations, the processing of complex shape connectors can be realized to meet the diverse needs of different electronic equipment connectors.

Applications

Mainly used in industries such as electronics, automobiles, and communications that require extremely high precision and reliability of docking plug-ins. In electronic equipment, it is used to produce various circuit board connectors, headphone sockets, USB interfaces, etc.; in the automotive field, it is used to manufacture connectors and sensor connectors in automotive electronic systems; in communication equipment, it is used to produce optical fiber connectors, radio frequency connectors, etc.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.