Description

Small bracket stamping parts refer to metal parts made by stamping process, which are used to support, fix or connect various small parts in electronic and electrical products.

Features

Small size: usually designed according to the specific space requirements of small parts or products, the length, width and height are generally between a few millimeters and tens of millimeters, which can accurately adapt to miniaturized equipment or parts.

Various structures: There may be various shapes such as L-type, U-type, T-type, and may also have different hole positions, protrusions or depressions to meet different installation and connection requirements. For example, some small brackets may have multiple mounting holes for fixing with other parts by screws or rivets; some may have specific shapes of slots for clamping or positioning other parts.

High precision requirements: Although the size is small, in order to ensure good fit with other parts, high requirements are placed on dimensional accuracy, shape accuracy and position accuracy. For example, the hole spacing tolerance of the bracket may be required to be within ±0.1 mm to ensure accurate connection with the corresponding parts.

Materials: Generally, metal materials with certain strength, toughness and good processing performance are selected, such as stainless steel, copper alloy, aluminum alloy and low carbon steel. Stainless steel has corrosion resistance and high strength, and is suitable for occasions with high environmental requirements; copper alloy has good electrical conductivity and thermal conductivity, and is often used in small brackets with electrical performance requirements; aluminum alloy is light and has high strength, and can be used for some products with weight requirements; low carbon steel has low cost, good comprehensive performance, and is widely used.

Manufacturing process

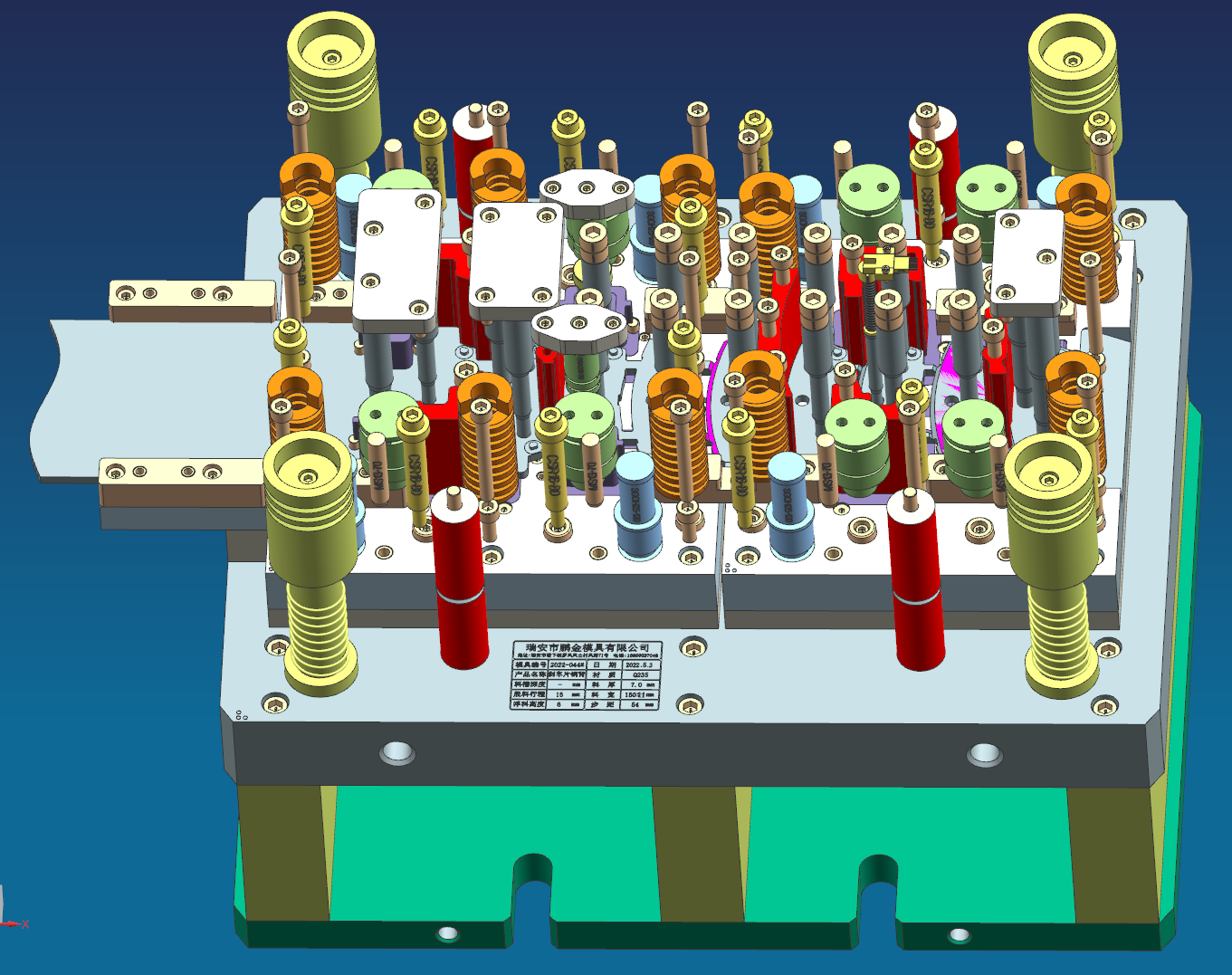

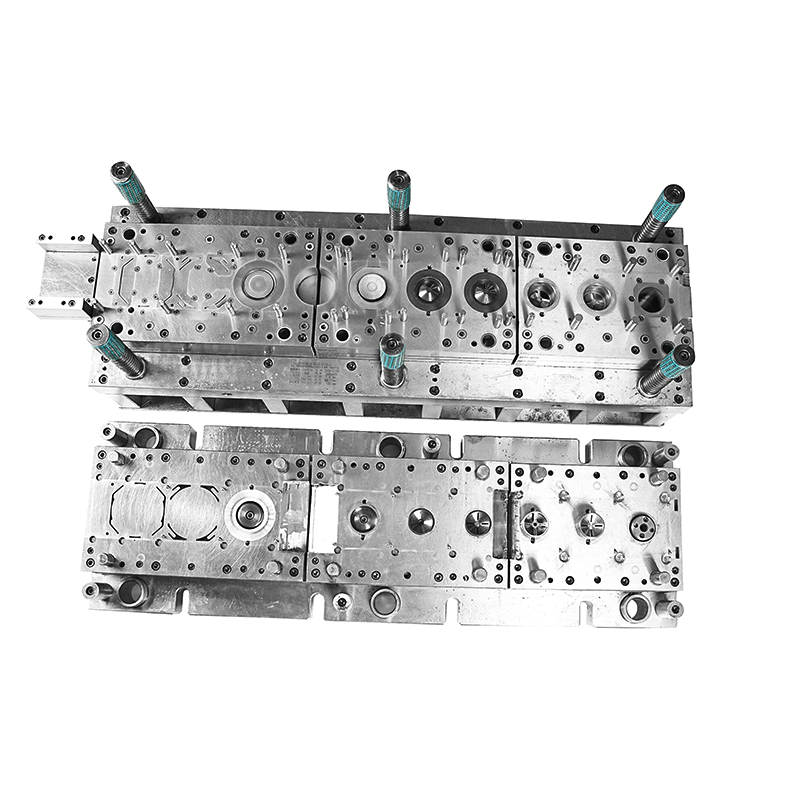

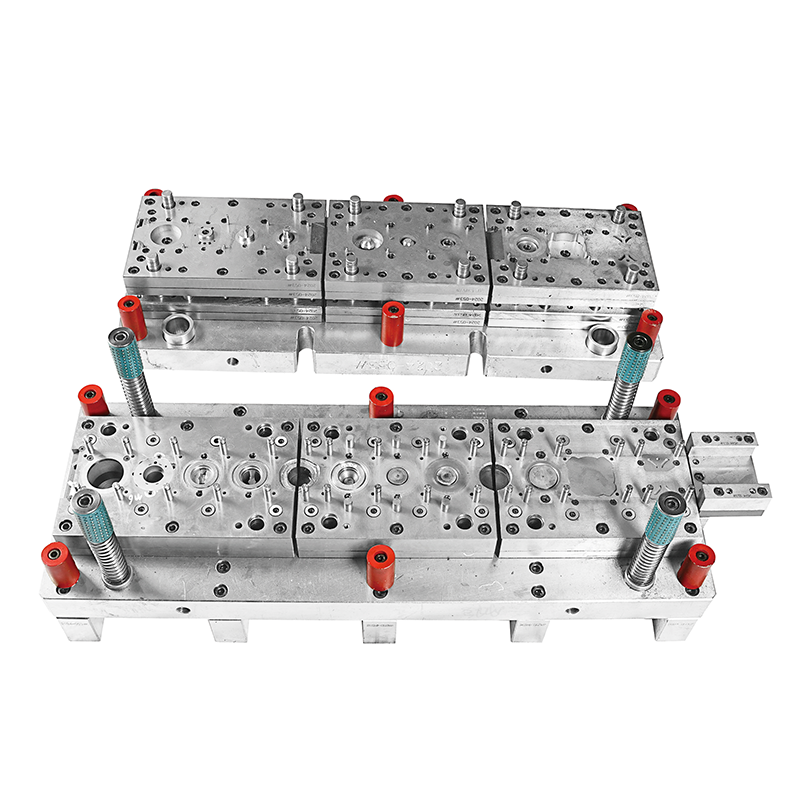

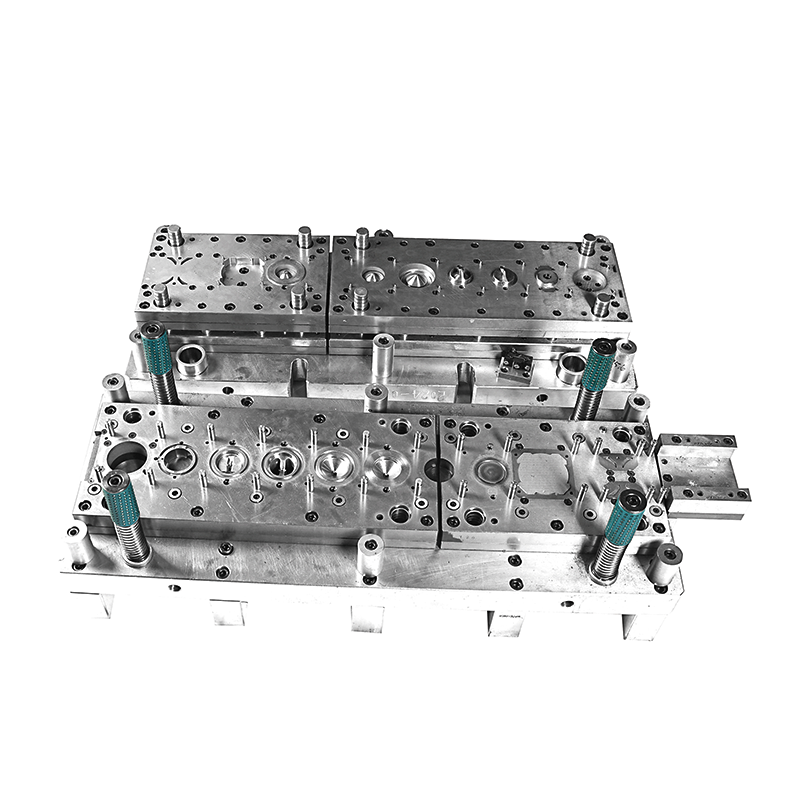

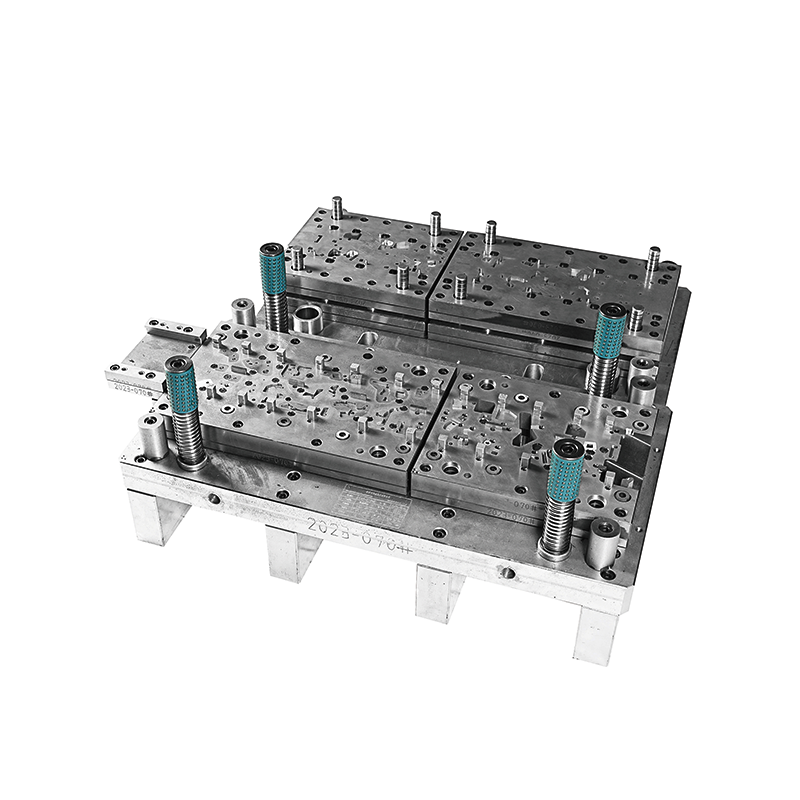

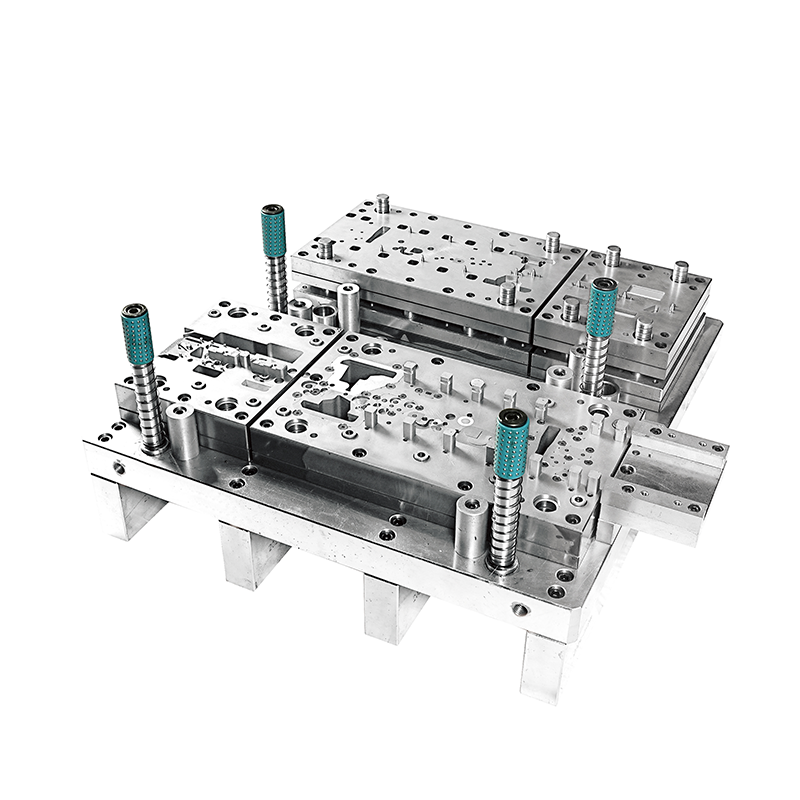

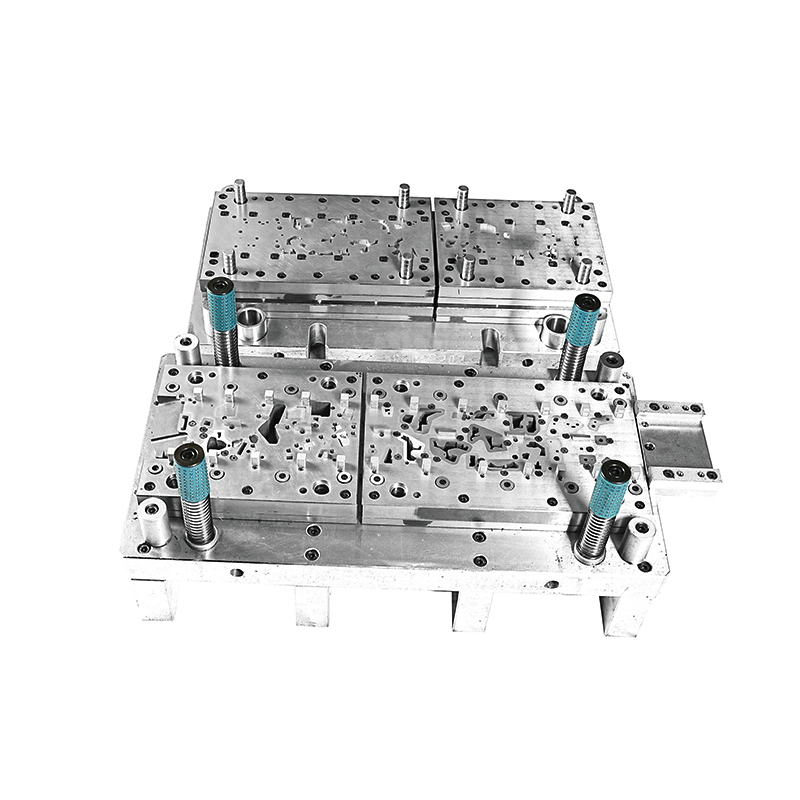

Stamping: This is the key process in the manufacture of small brackets. The metal sheet is pressed by the punch and die to cause plastic deformation to obtain the desired shape and size. First, the metal sheet is cut into a suitable blank, and then put into the die for stamping, which may include punching, blanking, bending, stretching and other stamping processes. For example, for a small bracket with a hole and a curved shape, it is necessary to punch the hole first and then bend it.

Surface treatment: In order to improve the corrosion resistance, wear resistance or conductivity of the small bracket, surface treatment is usually performed. Common surface treatment processes include electroplating (such as nickel plating, zinc plating, chrome plating, etc.), spraying (such as plastic spraying, spray painting, etc.), oxidation treatment (such as anodizing), etc. For example, nickel plating can improve the corrosion resistance and surface hardness of small brackets, while enhancing their conductivity; plastic spraying can provide good insulation performance and beautiful appearance.

Applications

Widely used in electronic and electrical products, such as mobile phones, tablets, laptops, digital cameras, etc.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.