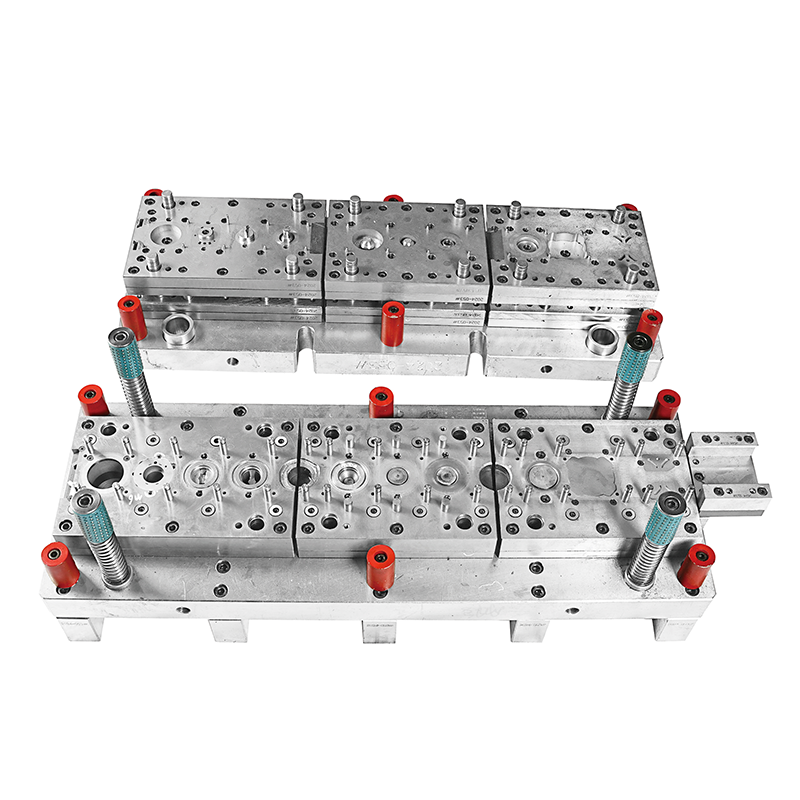

Serrated metal stamping die for tread and grip applications

Going to the texturing and notching of the surfaces, serrated metal stamping die is perfect for creating steps, grip plates, and safety surfaces. The area where such dies are often used is building, transportation, and industrial equipment.

The make of the die features carbide-lined profiles and wear resistant coatings to continuously keep the edge intact and the die running smoothly in high load operations. A variety of punches can be used for customized patterns or for the change of parts.

Focusing on safety, longevity, and simplicity of servicing our serrated stamping die not only improves the product functionality in the most demanding situations but also reduces risks of occupational accidents in the work areas.

Copyright © Pengjin Mold | Privacy policy