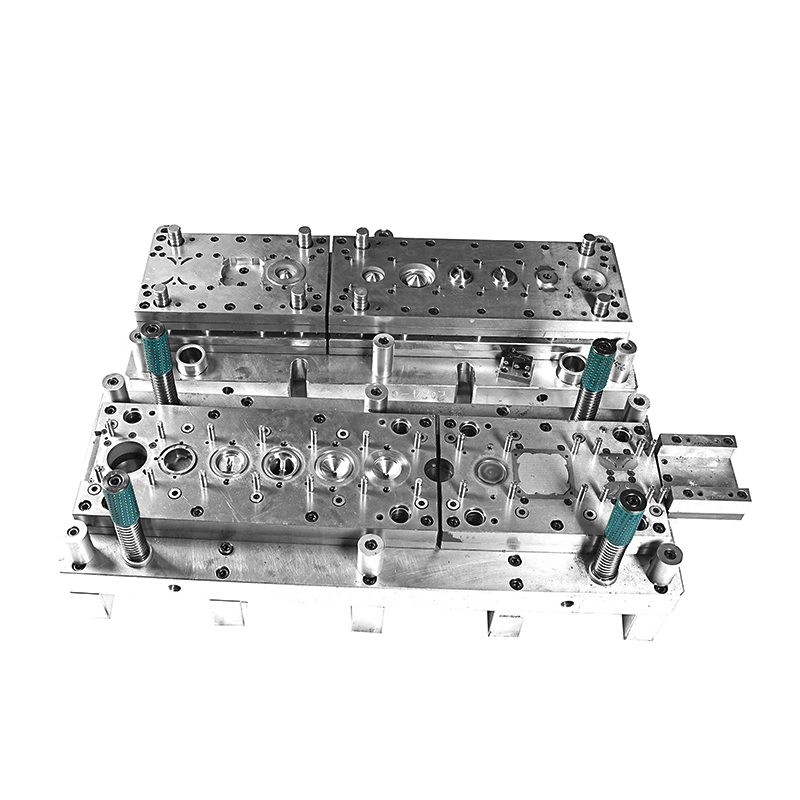

Precision Engineered Metal Stamping Die for High-Volume Production

Our metal stamping die is a high-grade option featuring precision and efficiency for mass production. It is made of rigid tool steel, and that is why it possesses high durability, even during prolonged manufacturing processes. Our dies will bring the required stamping accuracy and tight fit to your fabricated automotive, electronic or even home appliance units whether you are from the automotive industry, electronic components industry, or appliance panels industry.

Utilizing the latest CAD/CAM software and CNC machining, every metal stamping die is built in a way that fits your specific requirements. Our plans integrate progressive die sets, compound dies, and transfer die capabilities so that they suit any design and manufacturing requirements you may have. The die parts are polished and subjected to heat treatment not only to reduce wear but also to minimize downtime and to speed up stamping.

This stamping die is the perfect solution for making the dies and for managing the changes in a highly automated press line. High repeatability, sharp part definition, and minimal material waste are some of the key attributes of applications for which the tool is suitable.

From the very beginning of mass production, we always contribute a lot to the project, including design, and always stand by it with our technological support. The parts of all the die sets are thoroughly examined resulting in one hundred percent passing from manufacturing to delivery. We are ready to be your metals forming solutions partner, as we have been serving satisfied customers in a wide range of industries for many years.

Install this stamping die to accelerate your operations, bring down your tooling costs, and have an edge over your rivals in the tightly competitive manufacturing sector of today.

Copyright © Pengjin Mold | Privacy policy