Description

Sheet metal stretching and stamping parts are various parts made of sheet metal materials through stretching and stamping processes. They are widely used in many fields such as machinery manufacturing, electronic equipment, and automobile manufacturing.

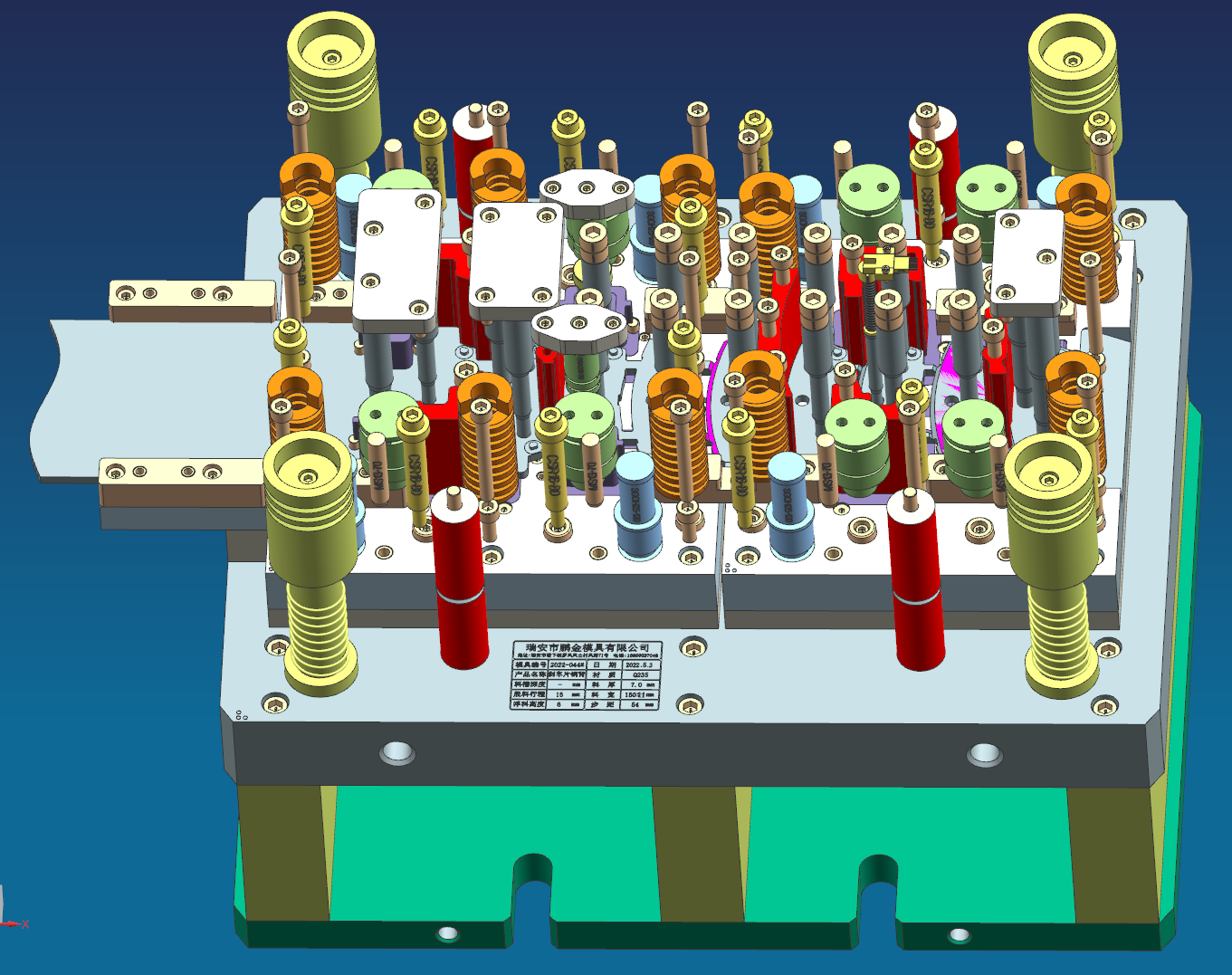

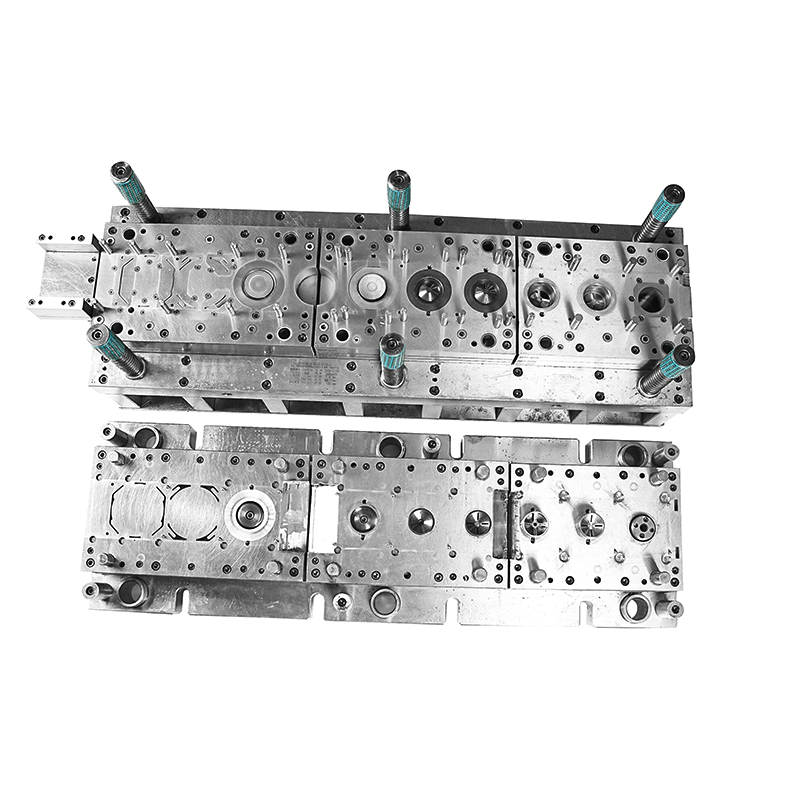

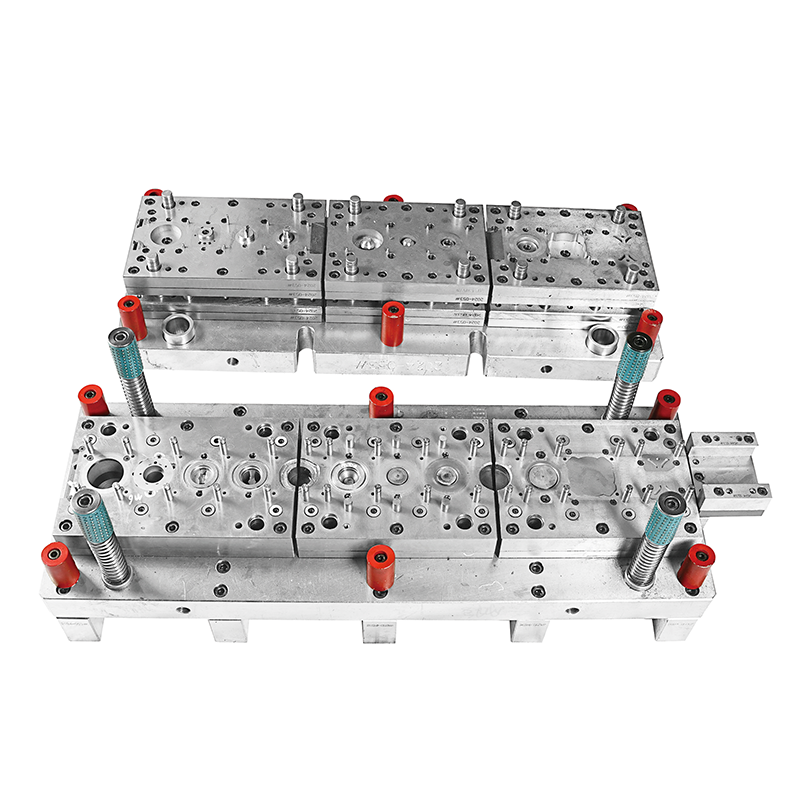

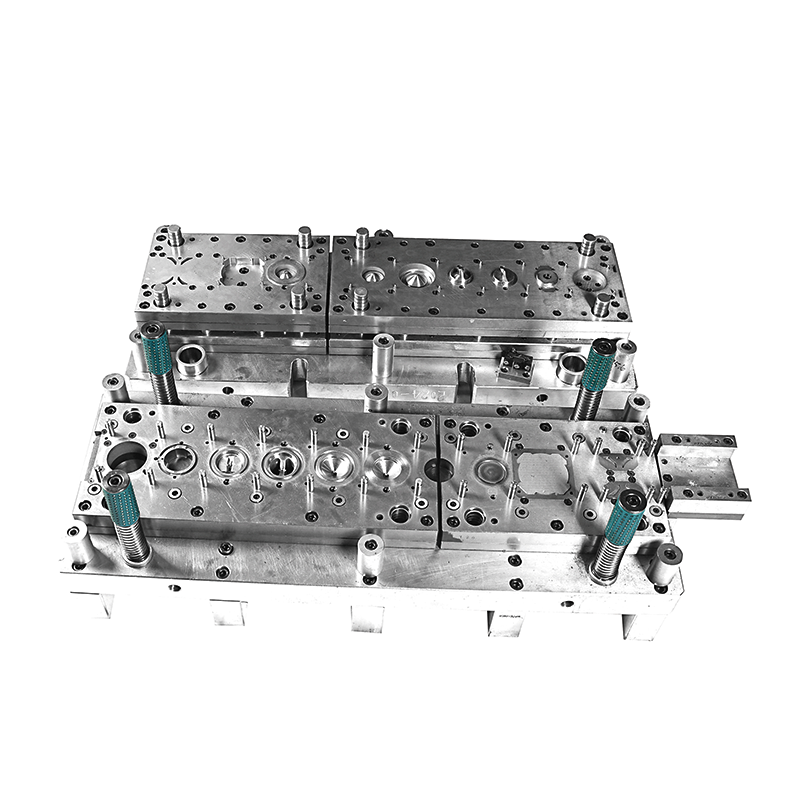

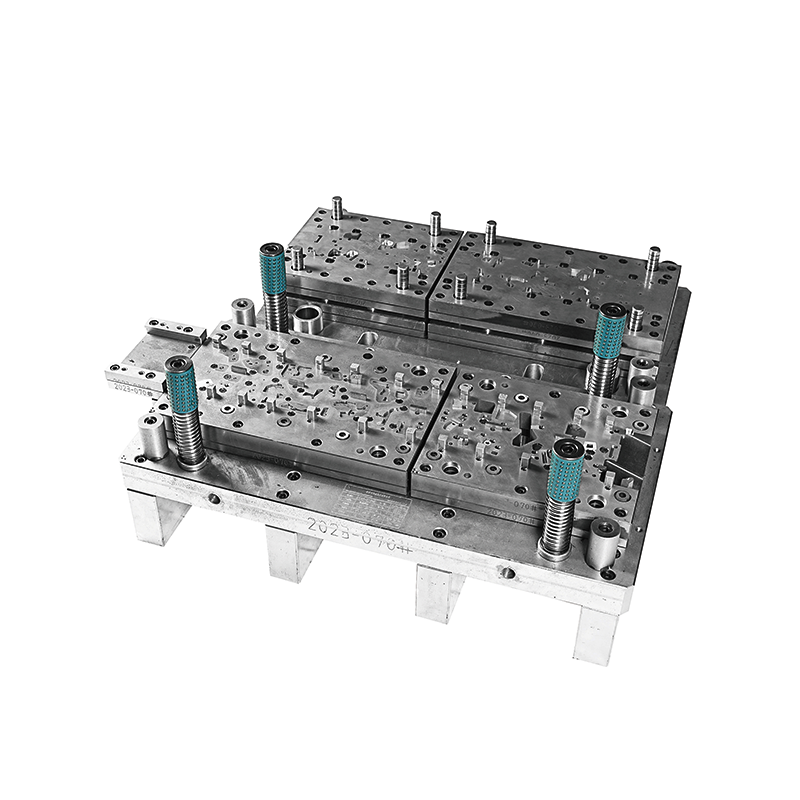

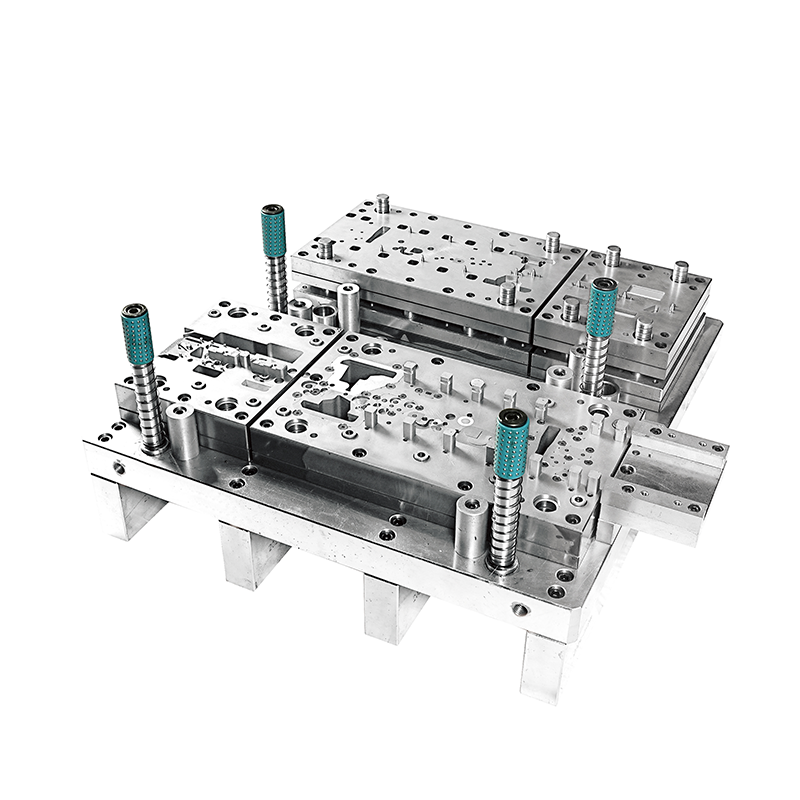

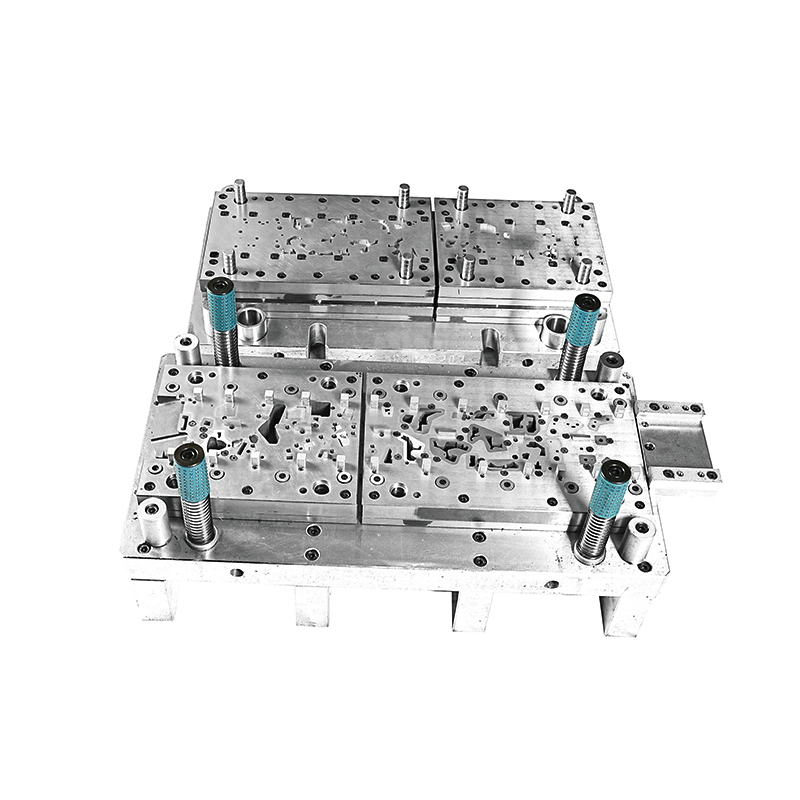

Manufacturing process: First, the sheet metal material is cut into suitable blanks according to the design size and shape of the parts. The stamping process is to use equipment such as a punch press to apply pressure to the blank using a die to separate or plastically deform it, complete punching, blanking, bending and other operations, and realize the initial forming of the parts. The stretching process is based on stamping, and further uses the die to stretch the flat sheet metal blank into a hollow part with a certain depth and shape, such as various shells and containers. During the stretching process, it is necessary to accurately control parameters such as the stretching ratio, die gap, and stamping speed to prevent defects such as cracking and wrinkling of the sheet metal material. For some complex sheet metal stretching and stamping parts, multiple stamping and stretching processes may be required, combined with other processes such as flanging and shaping to complete the final processing and manufacturing.

Commonly used materials: Commonly used sheet metal materials include low carbon steel, which has good toughness and processing performance, low cost, and is suitable for parts with general strength requirements; stainless steel, such as 304, 316 and other models, has excellent corrosion resistance, oxidation resistance and high strength, and is often used in occasions with high environmental adaptability and hygiene requirements; aluminum alloys, such as 5 series and 6 series aluminum alloys, have the advantages of light weight, high specific strength, and good corrosion resistance, and are widely used in aerospace, automobile lightweight and other fields; in addition, there are materials such as copper and copper alloys, which have good electrical and thermal conductivity and are often used in the manufacture of special parts in the electronic and electrical industry.

Function: Sheet metal stretching and stamping parts play an important role in different industries. In the field of mechanical manufacturing, it can be used to manufacture equipment housings, protective covers, workbenches, etc., which play a role in protecting the internal structure of the equipment and providing an operating platform; in the electronic equipment industry, such as computer cases, server cabinets, etc., it is a key component for protecting electronic components, achieving electromagnetic shielding and heat dissipation; in automobile manufacturing, body covers, engine hoods, doors, etc. are typical sheet metal stretching and stamping parts. They not only constitute the appearance of the car, but also bear certain structural strength and safety protection functions. In short, sheet metal stretching and stamping parts have become an indispensable and important type of parts in modern industrial production with their diverse shapes, good performance and low cost.

Applications

Widely used in many fields such as mechanical manufacturing, electronic equipment, and automobile manufacturing

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.