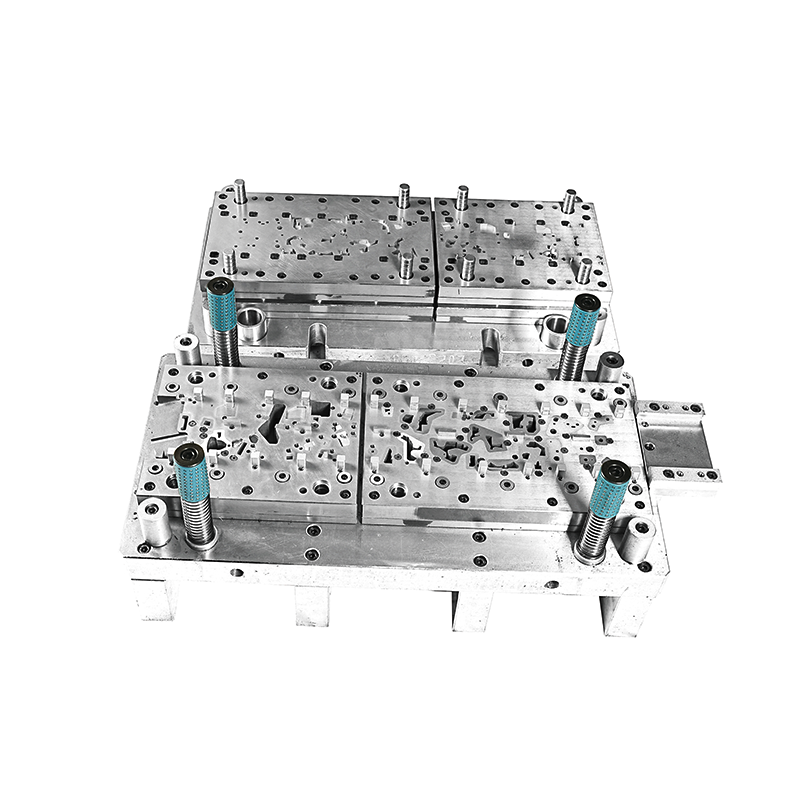

Heavy-Duty Metal Stamping Die for Industrial Manufacturing

Our heavy-duty metal stamping die is constructed on the strength and durability protocol and is designed to withstand the strenuous challenges of industrial engineering. It can be used in operations of high tonnage to forge thick-gauge steel, stainless, or even aluminum components, and is thus the most suitable.

Implementation of rugged CAD/CAM and CNC-machining technologies along with the tightest of tolerances guarantees the potential of this metal stamping die to create those few products that sizeable parts of not-so-small items will need such as machine housings, industrial enclosures, or agricultural equipment parts.

The die becomes one that is always accurate if die shoes, inserts made of wear-resistant materials, and a guided punch system of the highest precision are used. The die hardening, nitriding, and surface polishing operations are all factors that can be done to the die to increase its lifetime and prolonged service.

In order to make the same die ideal for use in hydraulic or mechanical presses, thus giving cannon of life to a variety of factory installations we are able to supply the same with full tooling documentation, on-site support for installation as well as spare parts kits in the long term.

OEMs and industrial contractors around the globe have faith in this type of metal stamping die because of its hardwearing, dependable nature, and its steady state of excellence. Small-sized press lines and stations without any human intervention lead to higher efficiency, reduced errors, and fewer downtimes.

Copyright © Pengjin Mold | Privacy policy