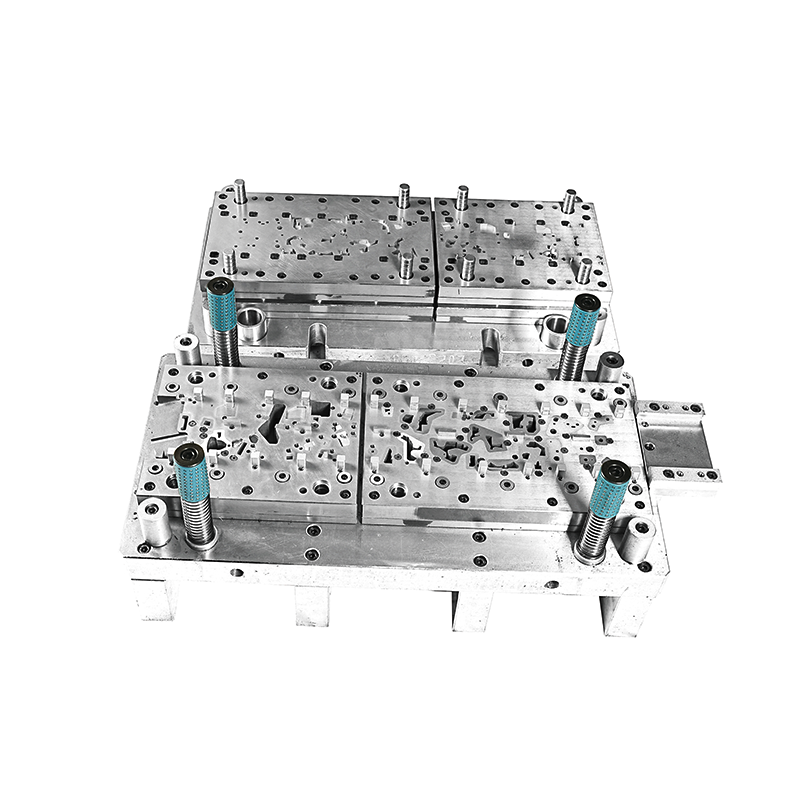

Progressive Mold for Medical Stainless Steel Instruments

Constructed to meet the needs of hygiene that are very demanding, especially in the case of surgical and diagnostic instruments made of stainless steel materials, the innovative and Taylor-made mold is the ideal tool for very accurate components production. The film was carefully planned in such a way that each of the stages would not be lenient on the quality of the operation: stretching, piercing, notching, and deburring need to be finished casually at every point without any stop in between. The form created from highly wear-resistant H13 tool steel, which was solidified by cold treatment, is what is here presented. Very sturdy indeed, the quick and hygienic mold plates that are easily washed are no stranger to sterile and cleanroom production conditions and the so-called quick-release plates for easy sterilization are together with them. Because of a minimal clearance of the die and an extremely polished surface, the spread of contamination and the stick of materials are both prevented. The designed neutron tool is quite flexible in terms of its usability for pressing purposes, the following are the examples of the parts: arms for forceps, instrument locks, and knife handles, with the result that the medical OEMs are able to get hold of the best possible efficiency and the least waste at the same time. It is replete with advanced features like sensors used for detection of out-of-spec parts or the press that are supposed to stop the line until the problems are solved. The mold is fitted with a press that has a speed of up to 200 SPM and is very precise, which maintains all tolerances. The die is thus a high-frequency production tool typically used in the mass production of high precision stainless steel components.

Copyright © Pengjin Mold | Privacy policy