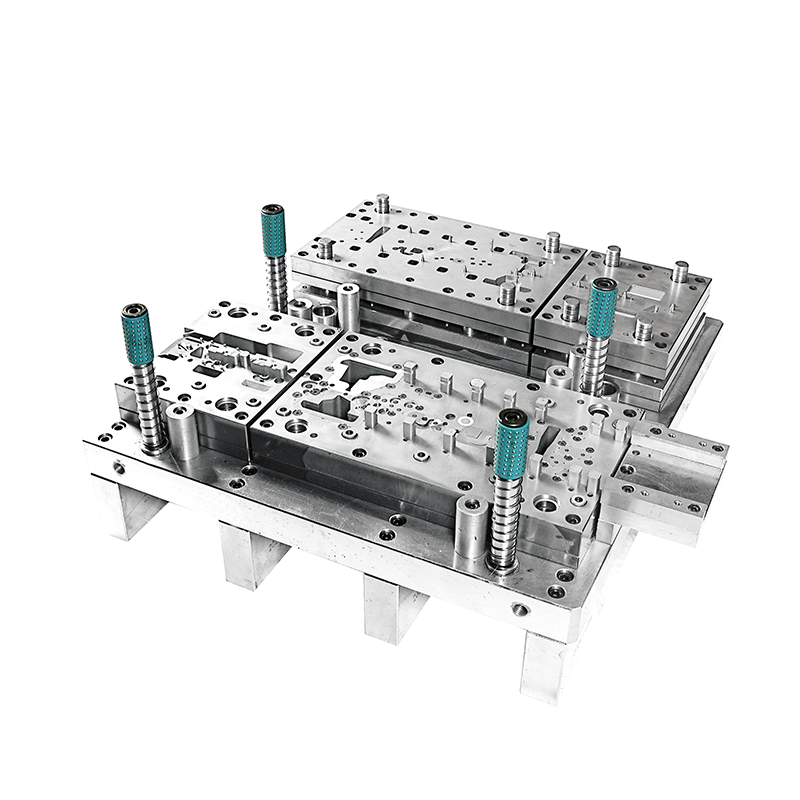

Cold Stamping Mold for Home Appliance Component Production

The cold stamping mold we supply for the home appliances sector is very well engineered and will be put in place for the extremely fast and precise manufacturing of the parts that will be used in air conditioners, refrigerators, washing machines, and microwaves. It is made to convert sheet metal into both functional and decorative parts just like exterior panels, mounting brackets, internal trays, and connector plates.

The cold stamping process is recommended for metals of small thickness such as galvanized steel and aluminum, which are basic in home appliance production. The mold creates forming, bending, and piercing actions at room temperature and leaves the material unharmed, maintaining its finish and structural integrity. It also reduces the need for extra processing, thus saving time and labor.

Our molds are made of high-performance tool steels such as SKD11 or Cr12MoV and are given heat treatment for improved strength. The dies are ground and polished with precision, thus smooth surfaces and clean forming edges are achieved. Complex parts are handled by a progressive mold system which brings together a variety of functions in just one move, thus giving a higher capacity of production.

This cold stamping mold is equipped with a proper combination of replaceable inserts, alignment guides, and cooling systems in order to ensure their lifetime performance during the very long production runs. We utilize a computer-aided design and computer-aided manufacturing (CAD/CAM) along with simulation software to guarantee the best design and visualize the material flow thus preventing common problems of cracks and warping.

In order that the life of the mold can be elongated, we can choose to cover it with some optional coatings such as TiN or by chrome plating. Our tools undergo several rounds of tests, including dry-run checks, tryouts, and CMM part measurement before shipping them, to ensure the accuracy and fit of the parts.

Naturally, the molds facilitate the appliance manufacturers by cutting down the number of rejected pieces, giving them a higher producing rate, and maintaining the uniformity of the products' high quality. This particular puncher die is an entirely high precision, long-lasting, and cheap for the manufacturing of today's competitive appliances.

Copyright © Pengjin Mold | Privacy policy