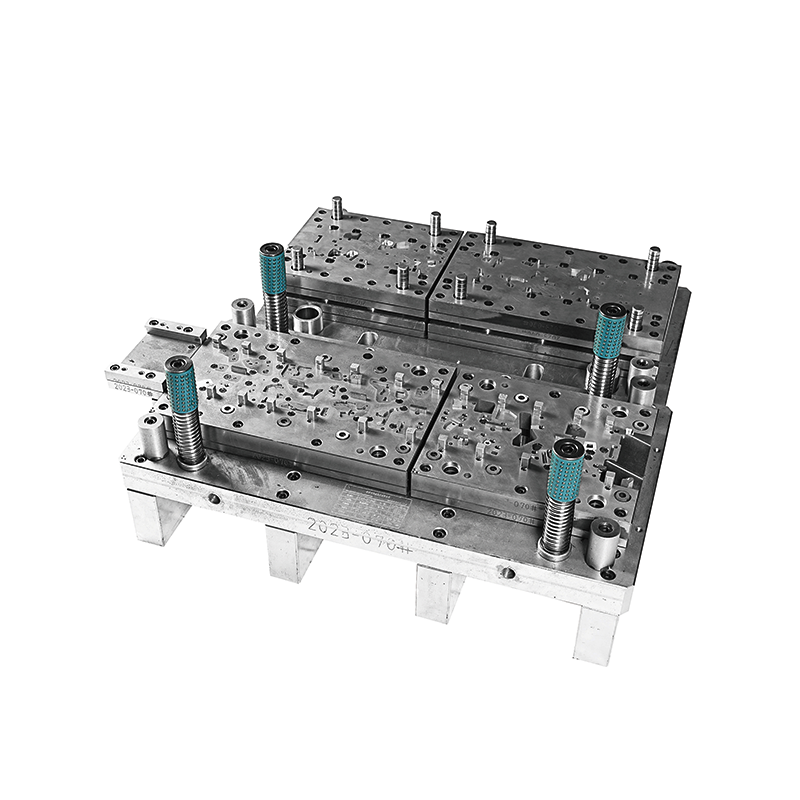

Progressive Mold for Heat Sink Stamping

This progressive tool is designed specifically for the aluminum and copper heat sink stamping that is used in varieties such as electronics, automotive, and power systems. By a well-coordinated process of punching, bending, and fin forming, heat sink shapes are gained which could have more surface area and hence have better thermal performance. The mold is produced from extremely hard SKD61 tool steel and is equipped with air-cooled punch guides for temperature adjustment during the operation. The controlled times and dimensional tolerances lead to a better performance of the array concerning the fin thickness and the spacing. Spreading some anti-friction layers helps to eliminate the interaction of the metals, which is common even at high speeds. The mold can be equipped with an inline brushing or de-burring unit to remove any dross or sharp edges on the parts so that they are ready for assembly. It can be immediately coupled with high speed progressive presses and also be integrated with robotic material handlers. This tool is characterized by steady thermal effectiveness, a small amount of residuals, and a stable output, designed for the high-volume heat sink production line.

Copyright © Pengjin Mold | Privacy policy