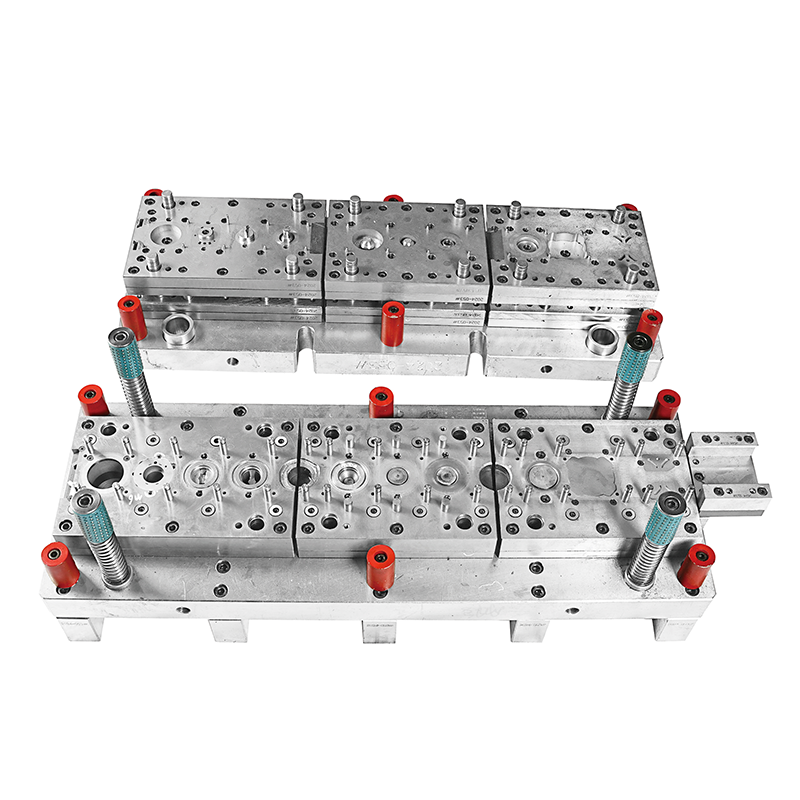

This metal stamping die provides automatic press line operation as well as enables the change of tools to be done fast for the highest throughput possible. It is a good choice for tasks that call for high repeatability, very sharp part definition, low or no material waste.

We are ready to help you in every step of the way from the initial prototyping stage up to the mass production of your product. Our house's own quality control process guarantees the good performance of a die which has been part of a very strict inspection prior to its delivery. We are well-staffed with experts who have extensive industry knowledge; our customers have come to trust us, therefore we are their partner in delivering complete solutions to their metal forming problems.

Buy our metal stamping die to get increased productivity, knockdown tooling expenses, and also keep an eye on the competition in the world’s ever-increasing market.

Copyright © Pengjin Mold | Privacy policy