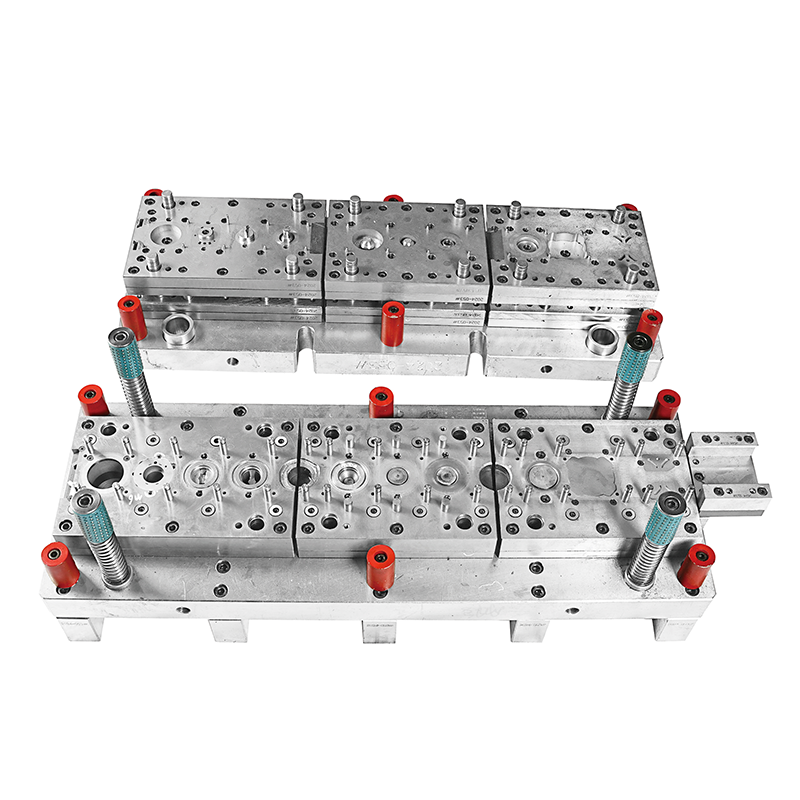

Hybrid Metal Stamping Die with In-Die Tapping Capability

Integrate the stamping and tapping inside with the help of the in-die tapping functionality in the hybrid metal stamping die for a faster process. The innovative die design is such that it permits both the cutting and the formation of a hole and the thread in one setting, thus limiting the number of the manufacturing process.

Its synchronized tapping units can simultaneously communicate with the press stroke, allowing the die to tap the thread while the press is forming the part. The tapping units we produce are both the fixed type and also the one that retracts.

The innovation of this die not only gives us a cutting-edge product but our customers as well. It is, for the most part, programmed at the CNC stage, then systematically checked out in live press form.

Utilizing this die will aid manufacturing companies in their product development due to reduced lead times while increasing the product's worth.

Copyright © Pengjin Mold | Privacy policy