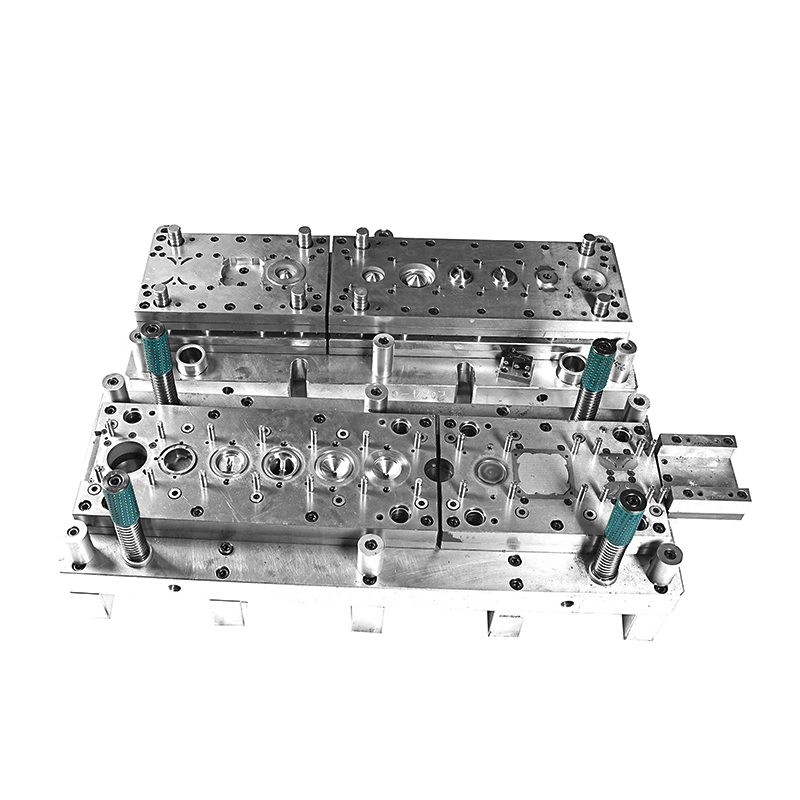

Aluminum Progressive Mold for Lightweight Enclosures

This aluminum progressive mold is incredibly good at the production of lightweight housings and enclosures for electronics and LED lighting. The mold can tackle very thin aluminum material of such gauges that range from 0.4mm to 1.5mm. The mold has special punches and dies coated to prevent both galling and oxidation. The whole process of shearing, forming, coining, and final shaping is synchronized by the high-precision guides and punch alignment pins. In addition, progressive mold uses a high-speed automatic feeder and permits adjusting die clearance for different aluminum grades. Utilizing modular insertion, the mold enables users to make quick changes in layouts to support the production of various product configurations. The progressive mold is specially designed for 24/7 mass production, so it is able to ensure the same surface quality and as a result, it decreases the post-processing needs. Its long tool life, efficient scrap management, and compatibility with standard stamping presses make it a very fantastic asset in the consumer electronics, lighting, and appliance industries.

The new forward-looking mold is capable of running two strips at once and hence, it achieves the production rate which is twice as efficient as a conventional one at a single press stroke. The design is characterized by a twin tool-carrying cage within a die set, which makes the metal strips advancing and processing be performed simultaneously and separately. Each station consists of punch sets, and stripper plates which are controlled in a high-precision manner that ensures both station and punch work synchronously. The tool is operator-friendly and performs tasks to user requirements even with very little manual intervention. Anytime the need arises, it is the best answer for equipment of high productivity, notwithstanding the fact that the footprints or the equipment size specifications remain constant. A central lubrication system, an individual scrap chute for each tool, and a set of sensorized die chambers are part of the manufacturing package offered by this mold. The already in-use servo presses are still applicable for the mold and stand to benefit from more options in functionality and speed control. Supported by yes, we had some ideas about what we would like to do with the material. e.g. 3D modeling and flow simulation, it obtained accurate and trouble-free material transportation. The mold also supports the user's intentions to boost production activities without having to spend more on production facilities. This dual-strip progressive mold is realistic and user-friendly. This will not only enhance your production capacity but also provide scope for better returns on the resources invested.

Copyright © Pengjin Mold | Privacy policy