Description

Wire harness stamping parts are a type of parts used to fix, connect and protect wire harnesses in the fields of automobiles, electronic equipment, etc., and are usually made of metal materials through stamping processes.

Features

Various shapes: According to different wire harness layouts and installation requirements, wire harness stamping parts have various shapes and structures, such as round, square, rectangular, special-shaped, etc., and some have holes, grooves, bosses, etc. of different shapes to adapt to wire harnesses of different diameters and specifications and different installation positions and methods.

High precision requirements: In order to ensure good coordination with wire harnesses and other related components, the dimensional accuracy and form and position tolerance requirements of wire harness stamping parts are relatively strict. For example, the inner diameter of the clip or clamp used to fix the wire harness needs to be precisely matched with the outer diameter of the wire harness, and the tolerance range is usually controlled within a smaller range to ensure the tightening effect of the wire harness and prevent the wire harness from loosening or shaking.

Good conductivity and corrosion resistance: For some wire harness stamping parts that need to transmit signals or currents, such as terminals, they are required to have good conductivity to ensure the stable transmission of signals or currents. At the same time, since these parts are usually exposed to different environments, they need to have a certain degree of corrosion resistance to ensure the stability of their performance and service life.

Materials:

Copper and copper alloys: They have excellent conductivity, thermal conductivity and corrosion resistance, and are commonly used materials for manufacturing wire harness stamping parts such as terminals that have high conductivity requirements. For example, pure copper has extremely high conductivity, while brass (copper-zinc alloy) has good strength and processing properties, and is more suitable for some occasions that have certain requirements for conductivity and strength.

Aluminum and aluminum alloys: They have the advantages of light weight and good corrosion resistance. In some equipment or products that have weight requirements, such as automobiles, aerospace, etc., they are often used to manufacture wire harness fixing clips, clamps and other parts. Aluminum alloys can further improve their strength and hardness by adding different alloying elements to meet different usage requirements.

Stainless steel: It has high strength, hardness and good corrosion resistance. It is suitable for manufacturing wire harness stamping parts used in harsh environments. For example, in high temperature, humid or corrosive gas environments, stainless steel wire harness fixtures can work stably for a long time and are not easy to rust and damage.

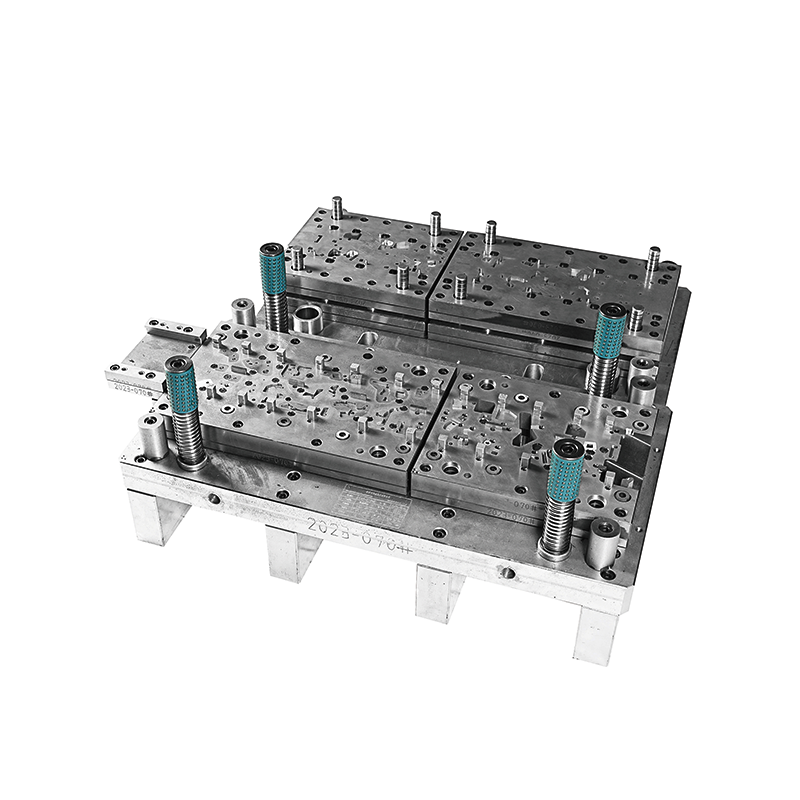

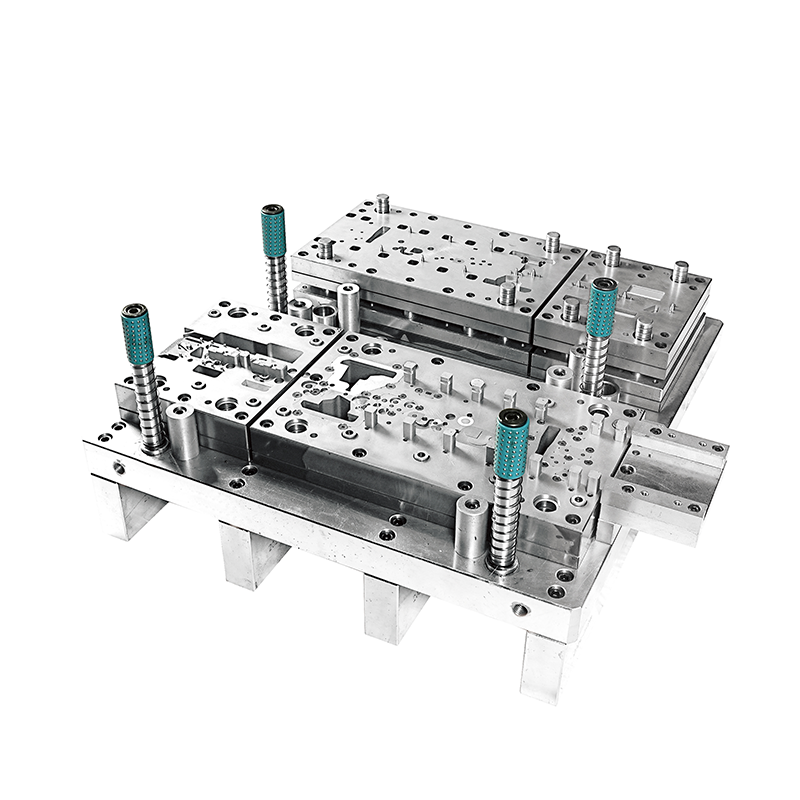

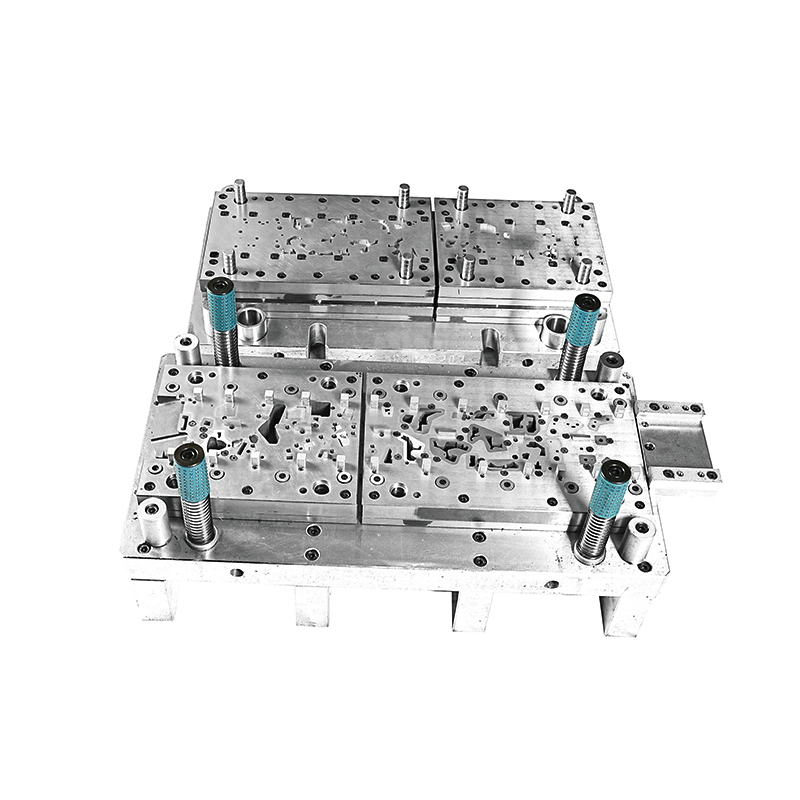

Manufacturing process

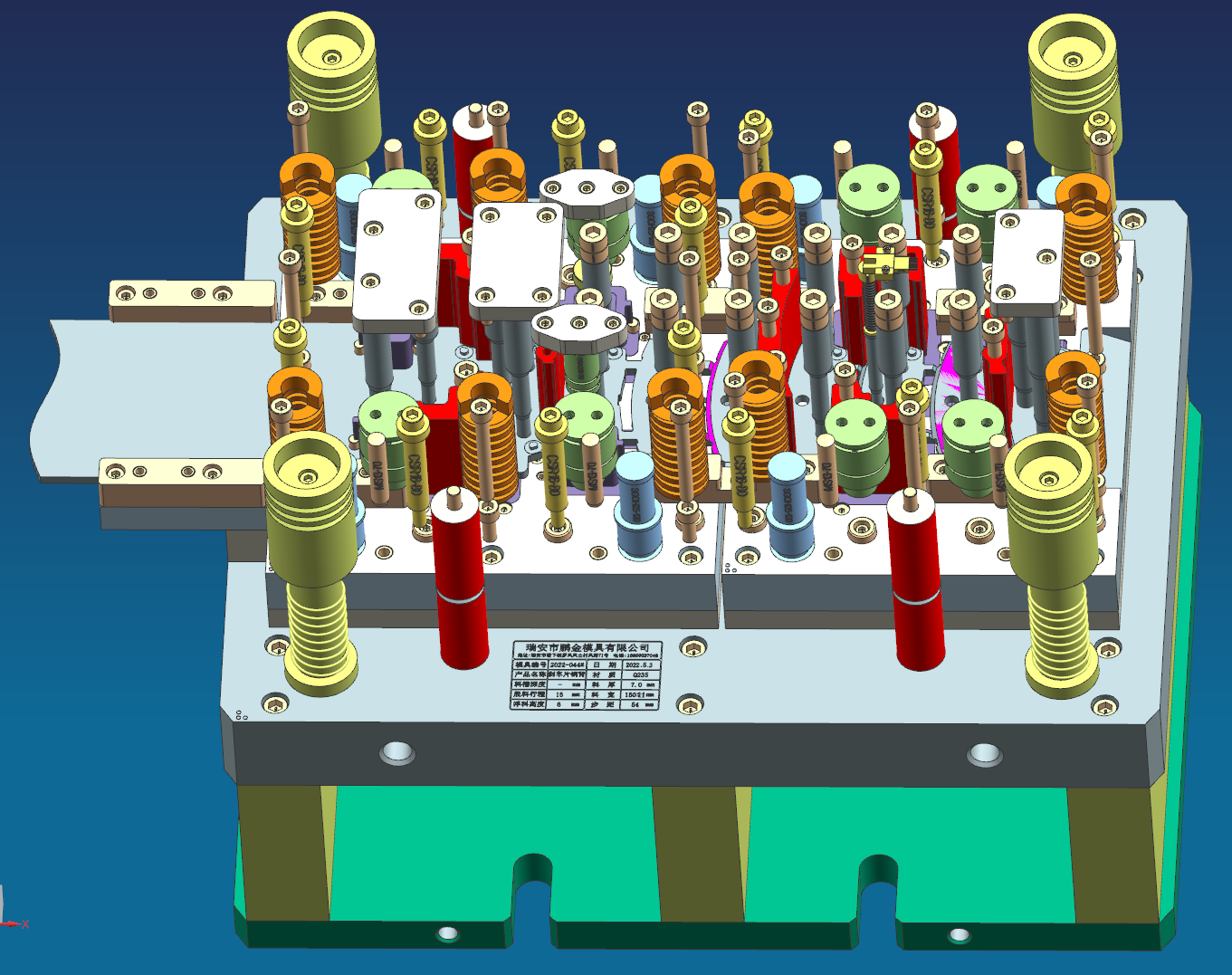

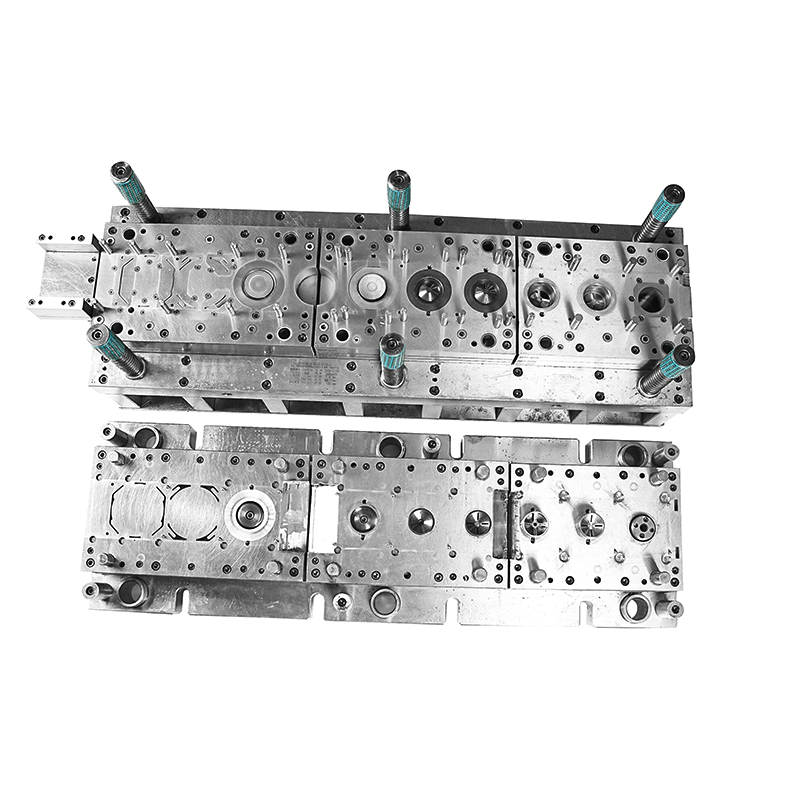

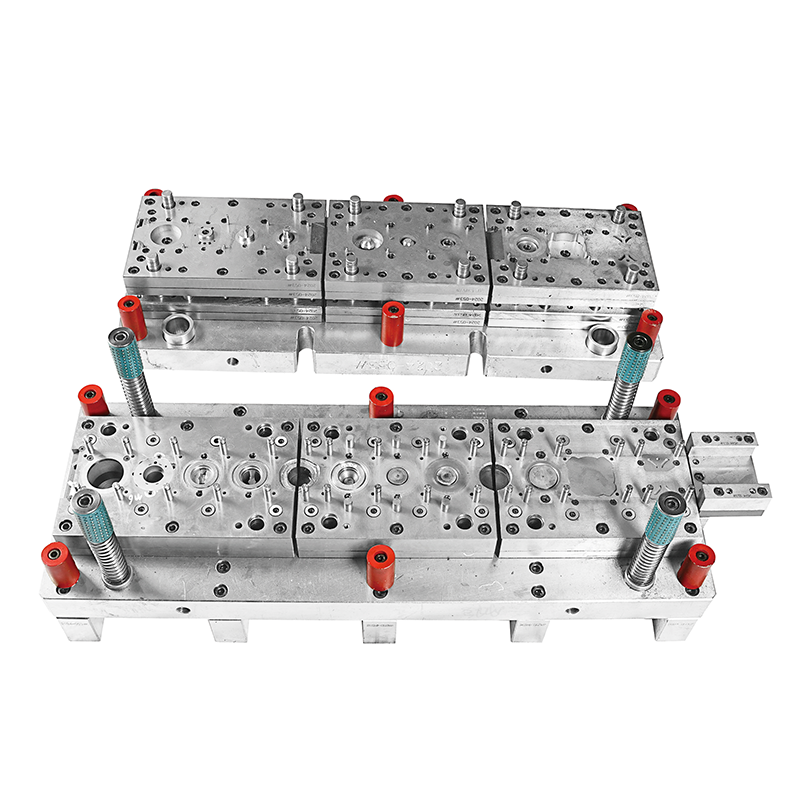

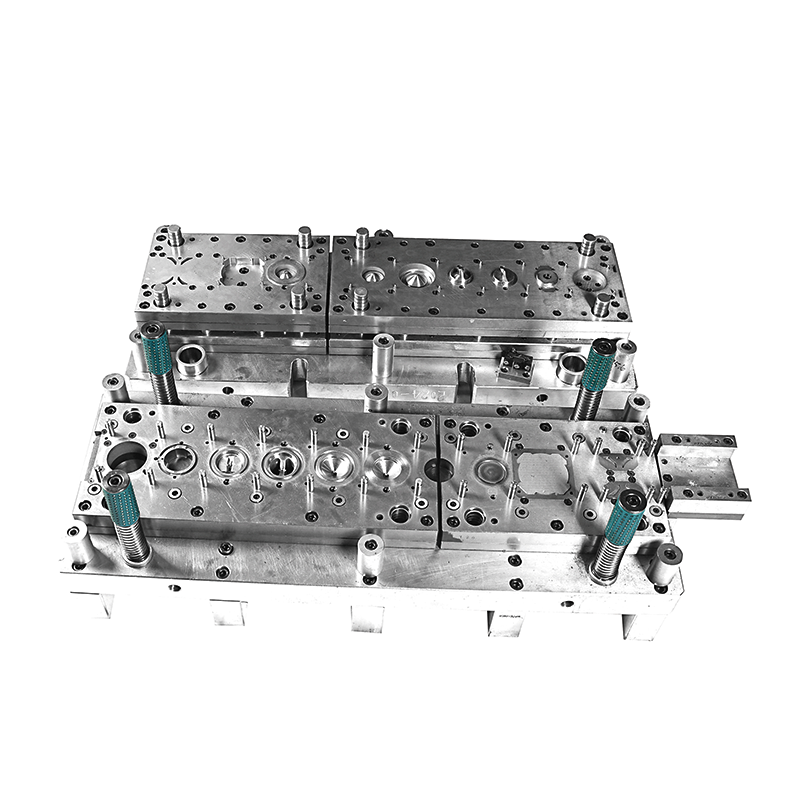

Stamping: First, according to the design drawings of wire harness stamping parts, make the corresponding stamping die. Cut the selected metal sheet into suitable blanks, put them into the stamping die, and apply pressure through the stamping machine to make the blanks plastically deform in the die to obtain the required shape and size. The stamping process may include punching, blanking, bending, stretching, flanging and other processes. For example, to manufacture a wire harness fixing clip, it may be necessary to first punch out the general outline of the clip through the blanking process, then form the shape of the clip through the bending process, and then process the mounting hole through the punching process.

Surface treatment: In order to improve the performance and appearance quality of wire harness stamping parts, surface treatment is usually required. Common surface treatment methods include electroplating, tinning, passivation, spraying, etc. Electroplating can coat a layer of metal, such as zinc, nickel, etc., on the surface of parts to improve their corrosion resistance and conductivity; tinning can improve the solderability of parts such as terminals; passivation can form a passivation film on the metal surface to enhance its corrosion resistance; spraying can form an organic coating on the surface of parts to play a protective and decorative role.

Applications

Widely used in the fields of automobiles, electronics, and industrial automation

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.