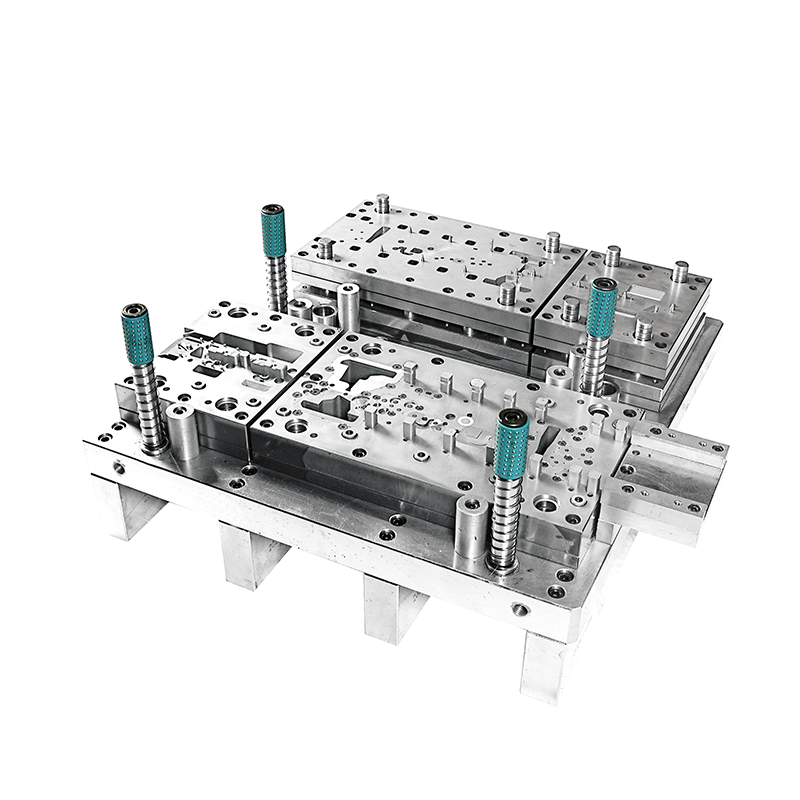

Cold Stamping Mold for High-Precision Metal Parts Production

The cold stamping mold we develop is targeted at the needs of the industries that have a necessity to attain high-precision metal parts. The new tooling solution is made of high-quality tool steel and fabricated through computer-controlled cutting and electro-discharge machining. This performance comes perfect for sheet metal forming activities requiring preciseness, promptness, and repeatable results.

Cold stamping (cold forming) is a metal deformation process that is conducted at room temperature rather than at high temperatures. This technology has multiple benefits compared to traditional hot working processes. The die used in cold stamping has nice dimensional tolerancing, good surface roughness, and increased material strength which is due to work hardening. Furthermore, it also eliminates the requirement for additional machining or secondary processing.

The creation of a punching, blanking, bending, flanging, and coining die set is what this cold stamping mold is optimized for. The described mold can be changed into either a single-station die or a progressive die that will significantly improve your production process based on the number of pieces and part complexity. Our design team collaborates closely with the customers in creating 2D and 3D CAD models, carrying out metal flow simulation, and practicing the most useful tooling layout for endurance and function.

Carbon steel, stainless steel, copper, aluminum, and brass are the most suitable materials to be used in the mold. This tool is also adaptable to high-speed mechanical presses and servo presses, so that the production line range extends from manual presses of small size and fully automated stamping systems.

Our cold stamping mold is widely used in the automotive, electrical, appliance, and hardware industries. This tool allows not only the mass production of structural brackets, terminal plates, heat shields, and decorative trims but also the attainment of other important components. Each mold is subjected to rigorous tests which include trial runs as well as inspection using CMM and vision systems to ensure that no defective parts are made.

Moreover, we can also provide such additional treatments as nitriding, chrome plating, and DLC coatings which will serve to prolong the life of the molds and reduce wear, especially when the production is a high volume. Along with each mold package, we offer deep and broad after-sales support, technical consultations, and spare parts at no extra charge.

If you are at the point of wanting a dependable solution to reach the goal of manufacturing high-quality stamped parts with superior productivity, and a small amount of waste, our cold stamping mold is going to give you the accuracy, the durability, and the long-term value most modern industries are looking for.}}

Copyright © Pengjin Mold | Privacy policy