Its conformity with presses of hydraulic as well as mechanical type endows the die with the capability to be used across various factory setups. We will give you the whole package of tooling documentation, support for installation at your site, and spare part kits, so you can do the maintenance in the long term.

The progressive design simplifies workflow, minimizes handling, and markedly cuts the time and cost of production.

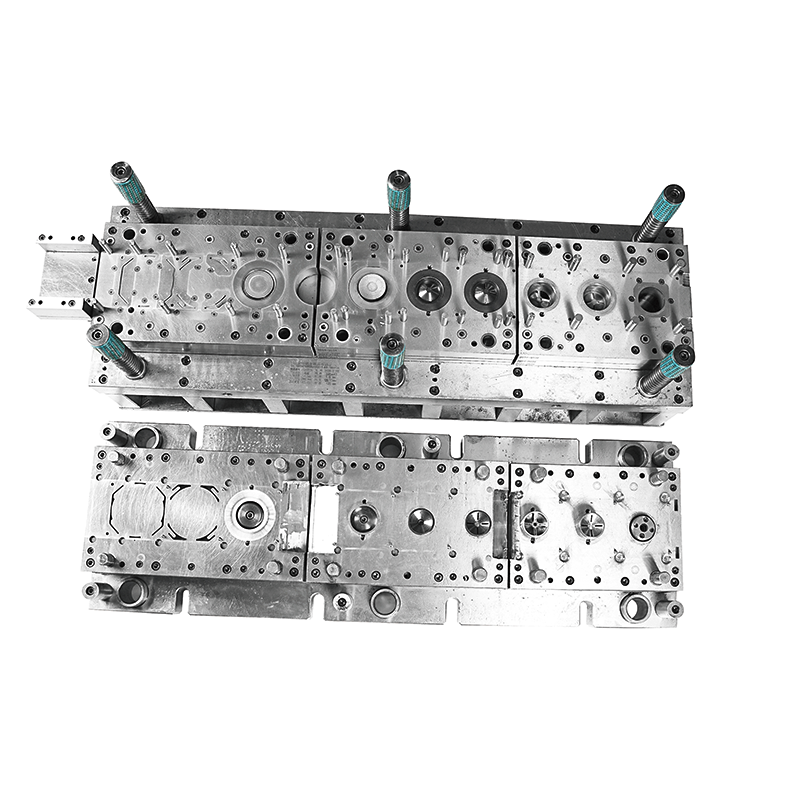

The respective tooling is equipped with some really cool elements such as punch inserts, stripper plates, and pilot pins, all made of wear-resistant materials and polished for easy maintenance.

We not only do the die design, but also provide service for the stage of sample verification and the production ramp-up. Our skilled technicians are there to make sure your die performs smoothly on your press line and also to connect it to coil feed and servo systems.

With the die underpinning consisting of hardened shoes, robust inserts against wear, and precise punch systems, irrespective of continuous heavy loads, the die ensures point-on-accuracy. Die hardening, nitriding, and surface polishing processes enhance tool life and lead to fewer tool replacements.

Whereas large contracts have been signed for the sale of this metal punching die all over the world, some of the contractors have been completely missed. This is the die you can rely on in every production cycle; this is the die that does not let you down. The power of the longevity of this stamping die can be clearly represented by the fact that it is of the heavyweight series.

Copyright © Pengjin Mold | Privacy policy