Description

Suspension stamping parts refer to metal parts manufactured by stamping process and used in vehicle suspension systems

Function: Suspension stamping parts are an important part of vehicle suspension systems. Their main functions are to transmit force and torque, buffer and reduce shock, and ensure the stability and controllability of vehicle driving. They can transmit the ground impact force of the wheels to the vehicle body, and reduce the impact of vibration and shock on the vehicle body through their own elastic deformation and shock absorption characteristics, making the vehicle more stable and comfortable during driving, and also helping to improve the vehicle's handling performance and safety.

Material: Generally, high-strength alloy steel or spring steel and other materials are used. These materials have good strength, toughness and fatigue resistance, and can maintain stable performance and shape under heavy loads, ensuring the reliability and durability of the suspension system. For example, 60Si2MnA spring steel is often used to manufacture shock-absorbing springs. It has a high elastic limit and fatigue strength, which can meet the shock absorption needs of vehicles under different road conditions; while control arms, suspension brackets and other components usually use high-strength alloy steels, such as Q345B, to ensure that they will not deform or damage under complex stress conditions.

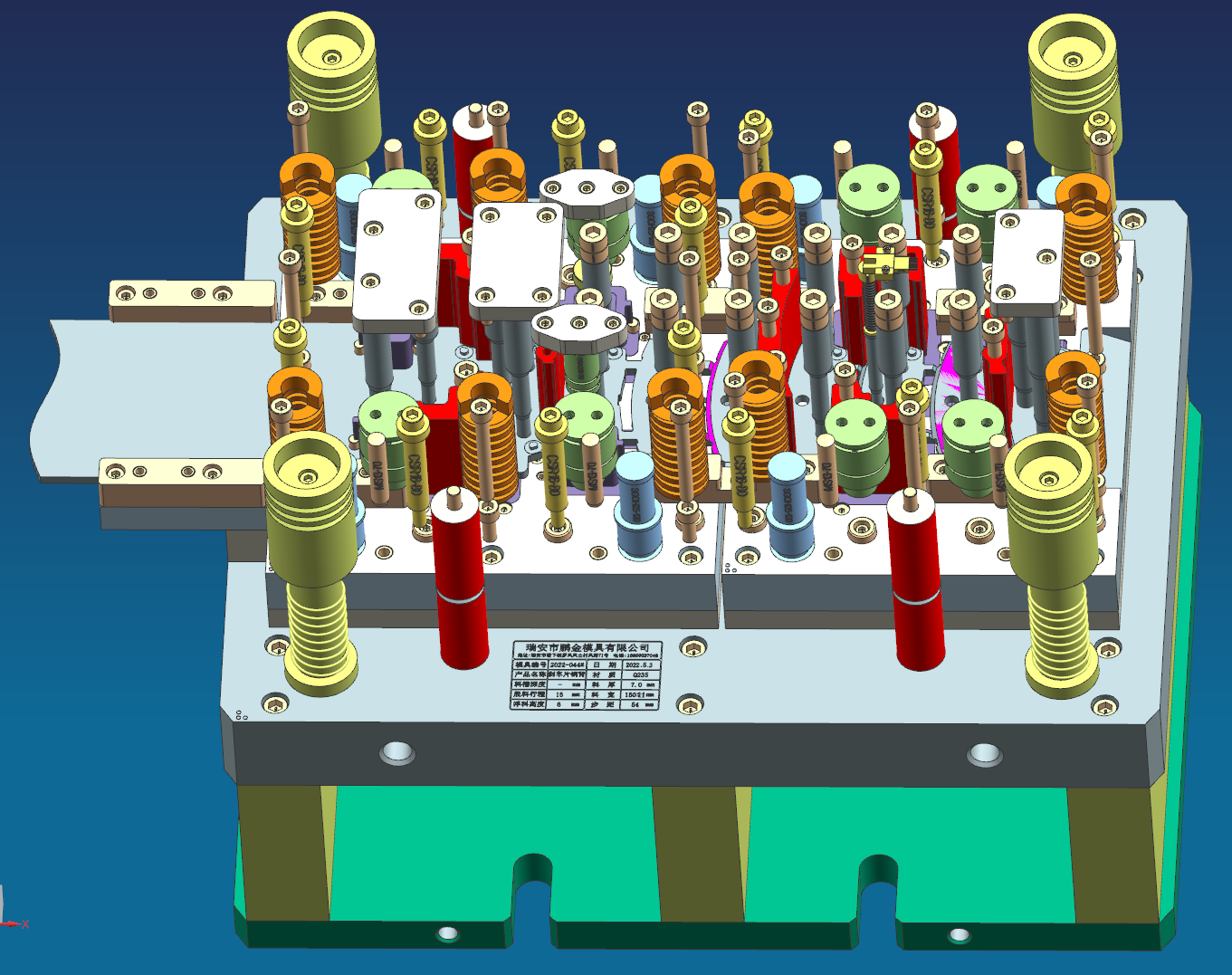

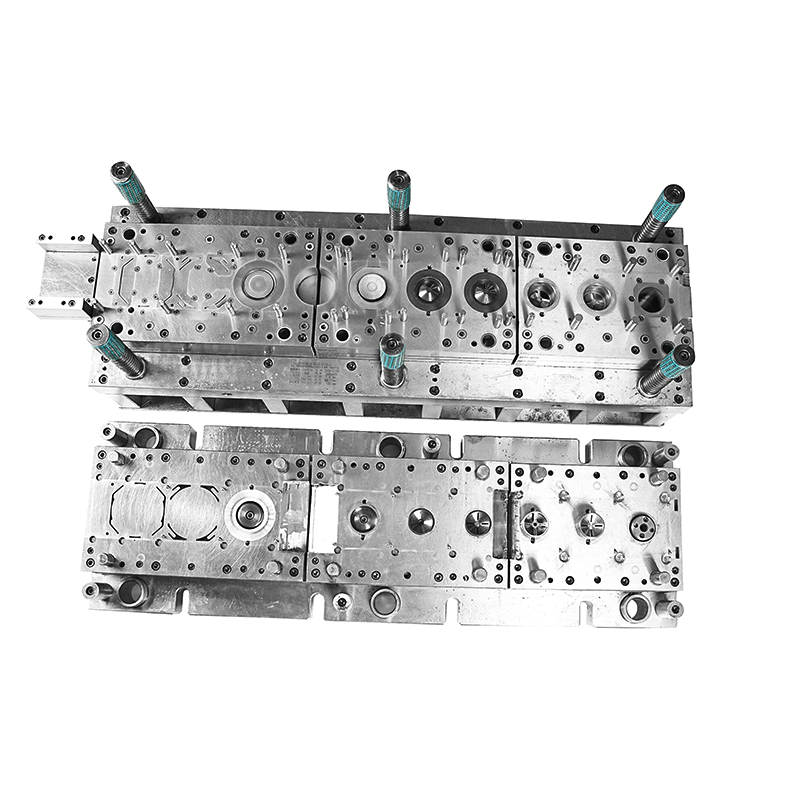

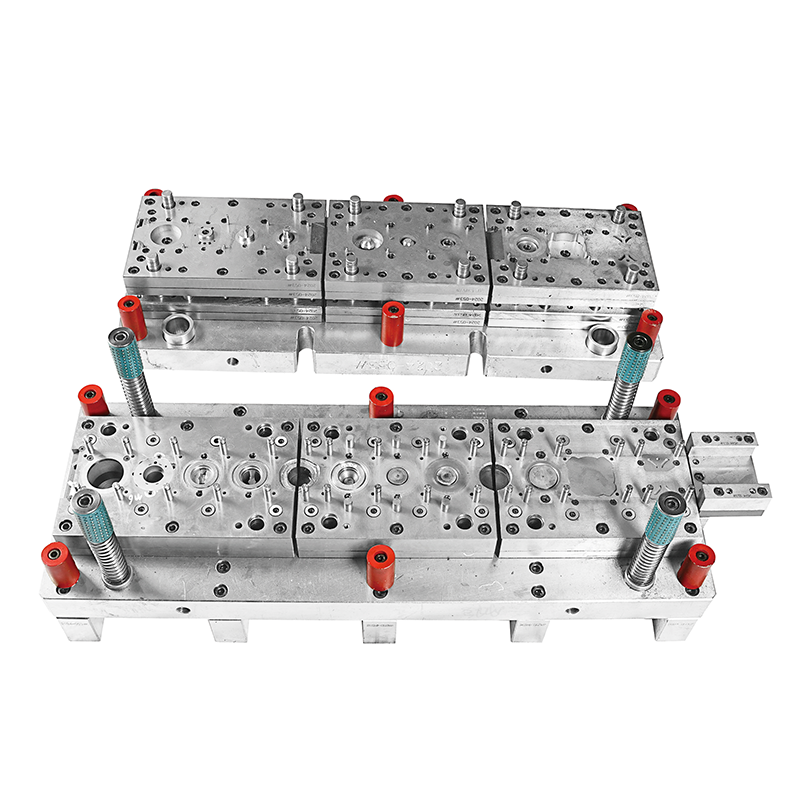

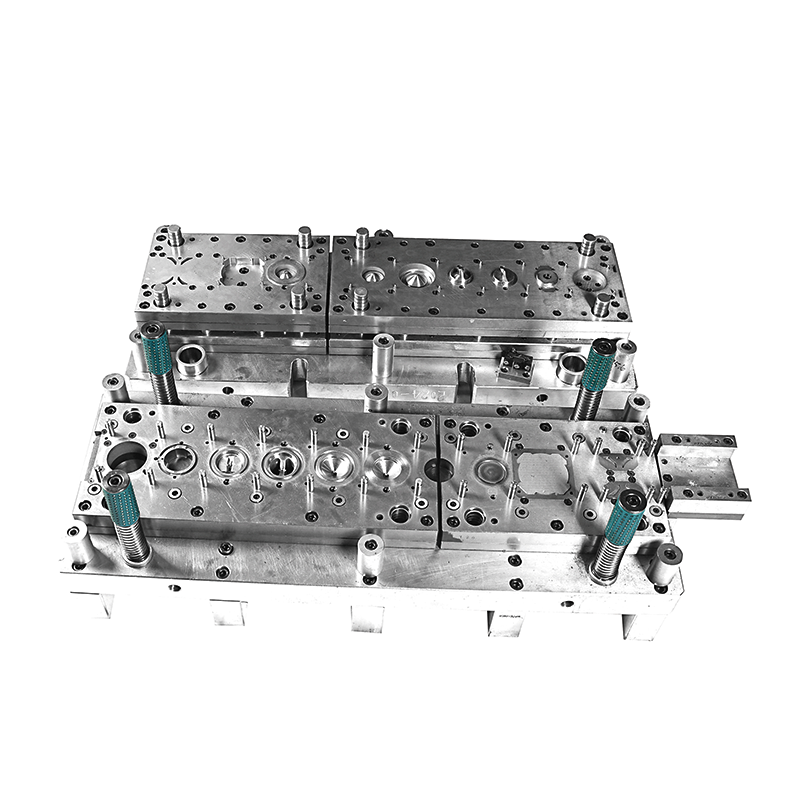

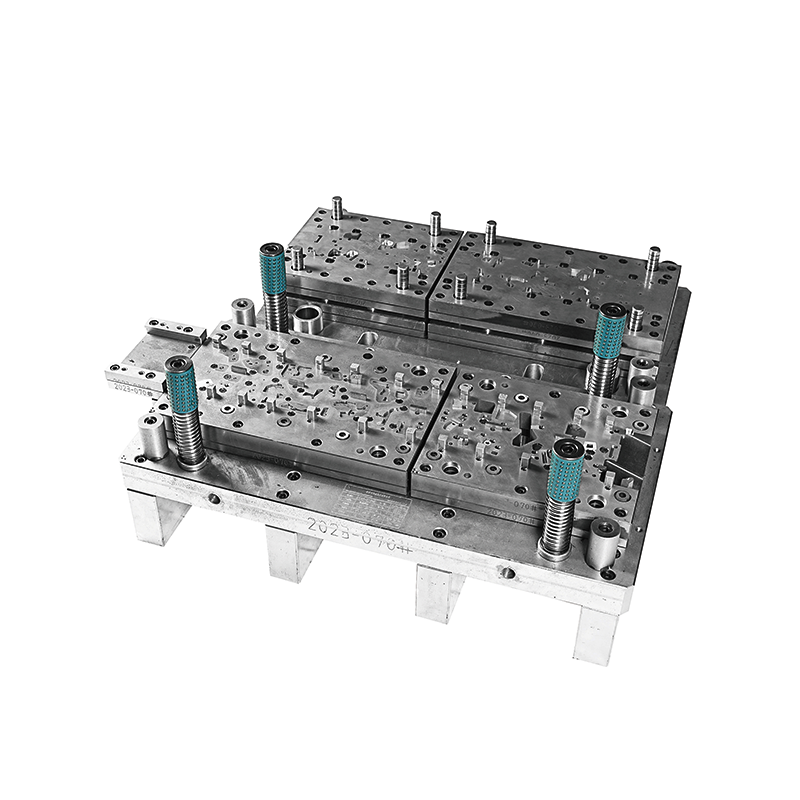

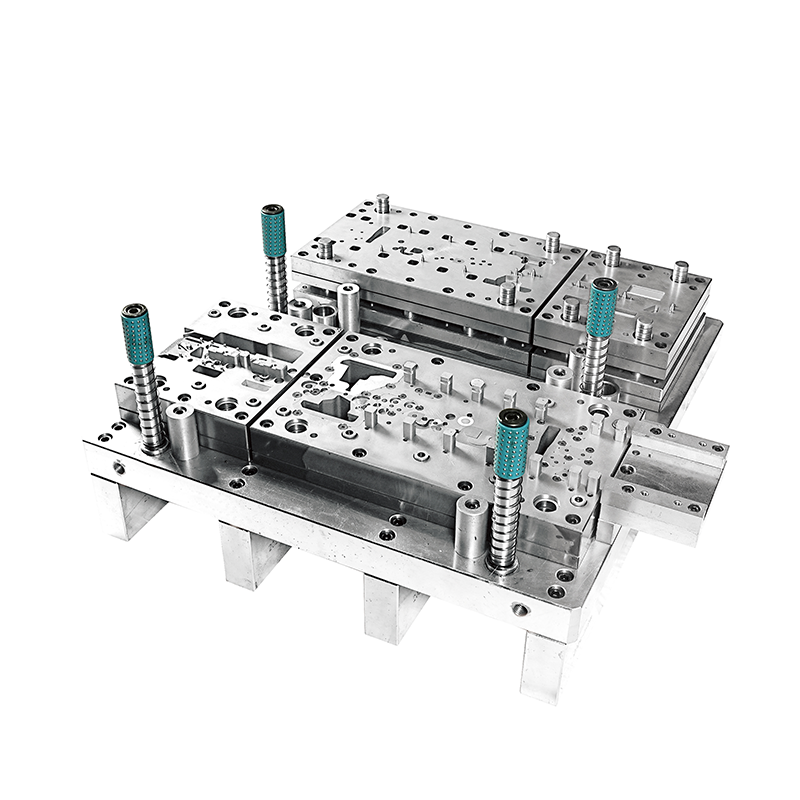

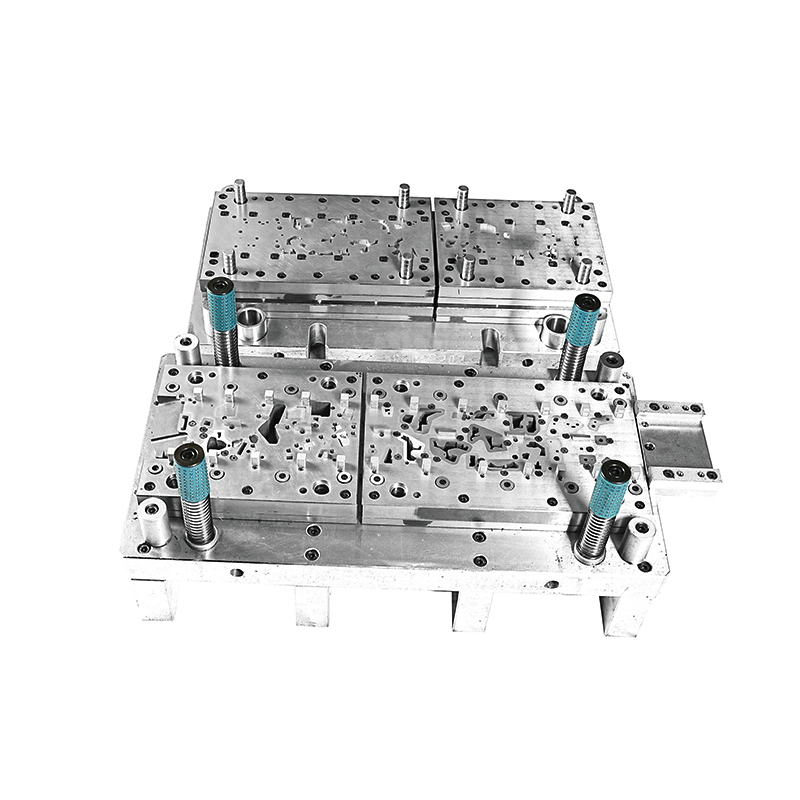

Manufacturing process: The manufacturing of suspension stamping parts mainly adopts stamping process, including cutting, punching, bending, forming and other processes. First, according to the size and shape requirements of the parts, the metal sheet is cut into a rough blank shape through the cutting process; then, various mounting holes and positioning holes are processed on the blank by the punching process; then, through the bending and forming process, the blank is gradually processed into the required shape, such as the curved shape of the control arm, the U shape of the stabilizer bar, etc. In the stamping process, high-precision molds and advanced stamping equipment are required to ensure the dimensional accuracy and surface quality of the parts. In order to further improve the performance and service life of the parts, some suspension stamping parts will undergo subsequent treatment processes such as heat treatment, surface quenching, shot peening and other subsequent treatment processes after stamping to improve their strength, hardness and fatigue resistance. At the same time, in order to prevent the parts from rusting and corrosion, surface protection treatments such as electroplating and spraying are usually performed.

Applications

Common types include: shock absorber springs, control arms, stabilizer bars, suspension brackets, etc., mainly used in: automobiles, motorcycles, engineering vehicles

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.