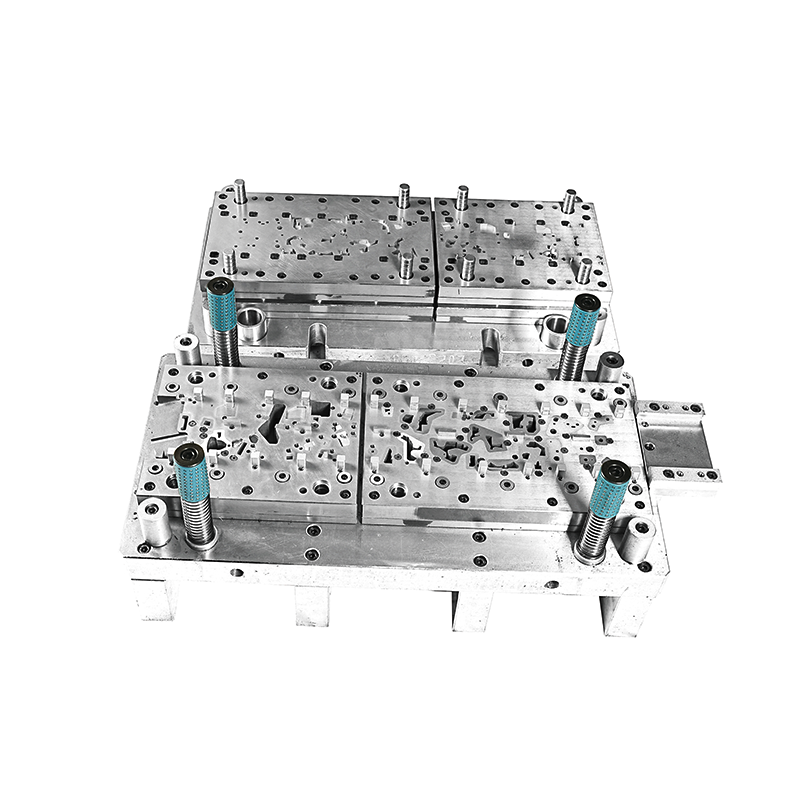

Compact Progressive Mold for Smart Wearbale Components

This compact progressive mold is specially designed for wearables, most notably small-sized components in smartwatches, fitness trackers, and all other kinds of wearables. Regardless of the small size, the mold does a totally different operation for each part: micro-piercing, shallow forming, fine blanking. These operations maintain the quality of the mold and make it possible to repeat them numberless times. The mold's producers were smart by selecting the combination of high-quality tool steel and a Titanium-Nitride coating to double the wear resistance and make the finish of their product much better. Due to the mold's structure, it is intended for use with thin nonferrous metals, e.g., copper foil or stainless steel. That way tearing or warping of materials is avoided. The mold is fitted with a micro-servo feed system, which by its nature, allows for continuous, high-speed, non-step-by-step feeding of fine-pitch part assemblies. The mold is thus able to make the product with a dimensional accuracy of ±0.01mm. That means it is a great fit for producers of wearable electronics that may want to add medical devices to their range of products and vice versa. The beauty of the mold's construction lies in the fact that it is easy to replace the tools, and no recalibration is required at all. The use of CAD/CAM technology and FEM simulation eliminated the possibility of the mold's deformation and the parts were optimally oriented. It thus becomes evident that the mold not only brings about the precise features but is also a time-saver and space-saver tool, therefore, the favorite for those who are engaged in the production of short-run, and high-mix pieces in consumer electronics.%20and%20heathcare.%20.

The most compact progressive mold for smart wearables on the market is displayed in the figure above. This mold ensures manufacturing efficiency and product quality by integrating multiple processes, from micro-piercing, shallow forming, to fine blanking, into a single operation. Not only is the hybrid of high-precision tool steel and titanium-nitride coating very efficient and printed the product's resistance to

Copyright © Pengjin Mold | Privacy policy