Description

Ignitor stamping parts refer to various metal parts used in ignitors through stamping process.

Features

High precision: The dimensional accuracy requirements of igniter stamping parts are high, especially for key parts such as electrode assemblies. Slight dimensional deviations may lead to problems such as insufficient ignition energy and inaccurate ignition position, affecting the normal operation of the igniter .

Good electrical conductivity and thermal conductivity: For electrode assemblies and connecting parts, good electrical conductivity is required to ensure that the current can be transmitted efficiently and sufficient electric sparks can be generated. At the same time, in order to prevent the heat generated during the ignition process from affecting other parts, these parts also need to have good thermal conductivity and be able to dissipate heat in time.

High temperature resistance and corrosion resistance: The ignitor will generate high temperature during operation and may be exposed to some corrosive gases or liquids. Therefore, stamping parts need to have high temperature resistance and corrosion resistance to ensure that they can still maintain good performance and long service life in harsh working environments.

Material

Metal alloys: The metal alloys commonly used to manufacture ignitor stamping parts include copper alloys, aluminum alloys and stainless steel. Copper alloy has good electrical and thermal conductivity, and is suitable for electrode assemblies and connecting parts; aluminum alloy has the characteristics of light weight, high strength and corrosion resistance, and is often used to manufacture igniter housings and some non-critical structural components; stainless steel has excellent corrosion resistance and high temperature resistance, and is suitable for igniter components with high environmental requirements.

Special materials: In some high-performance igniters, special metal materials such as tungsten and molybdenum may be used. These materials have higher melting points and better high-temperature resistance, can withstand higher ignition energy and more severe working conditions, and are often used to manufacture key components such as high-performance ignition electrodes.

Manufacturing process

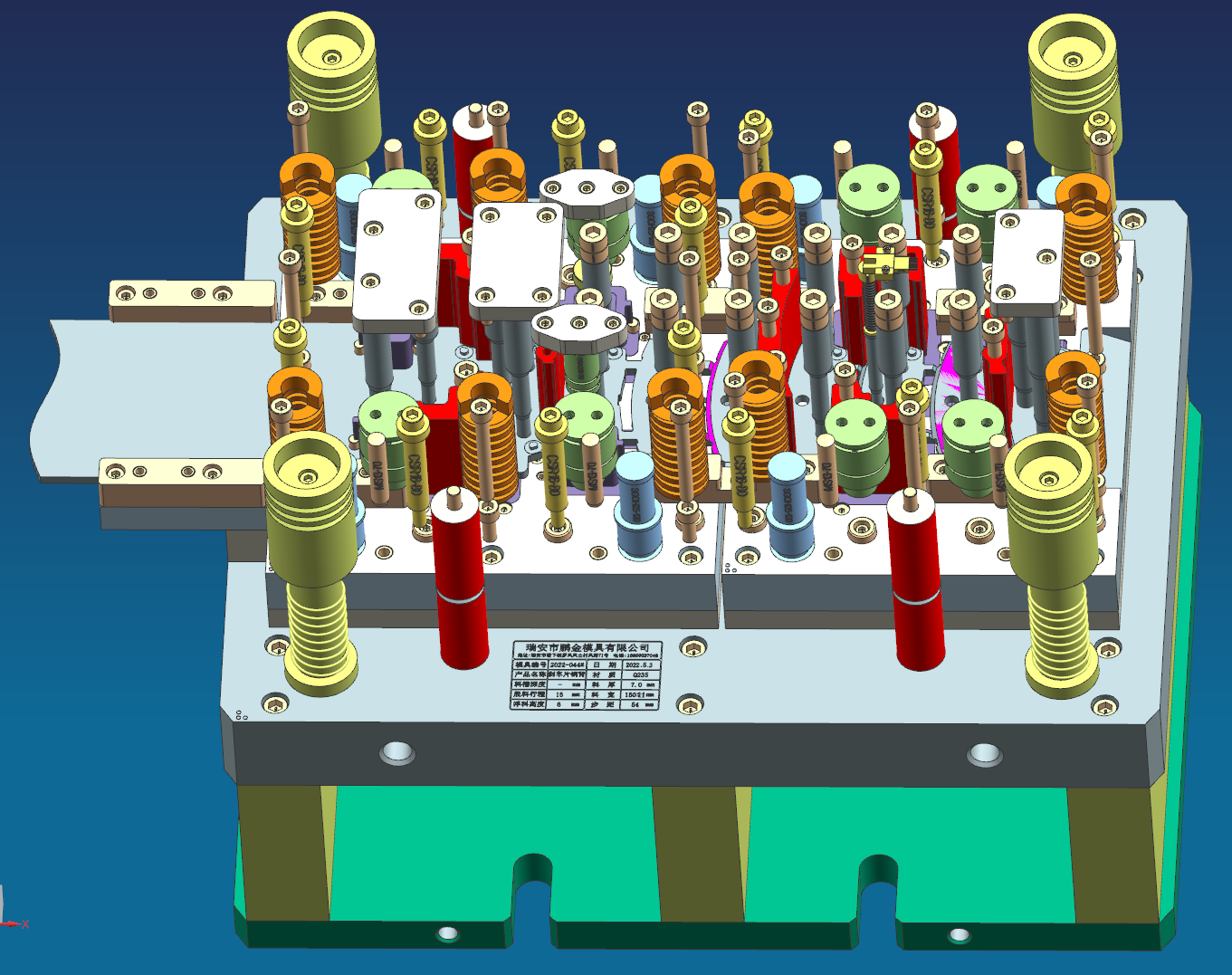

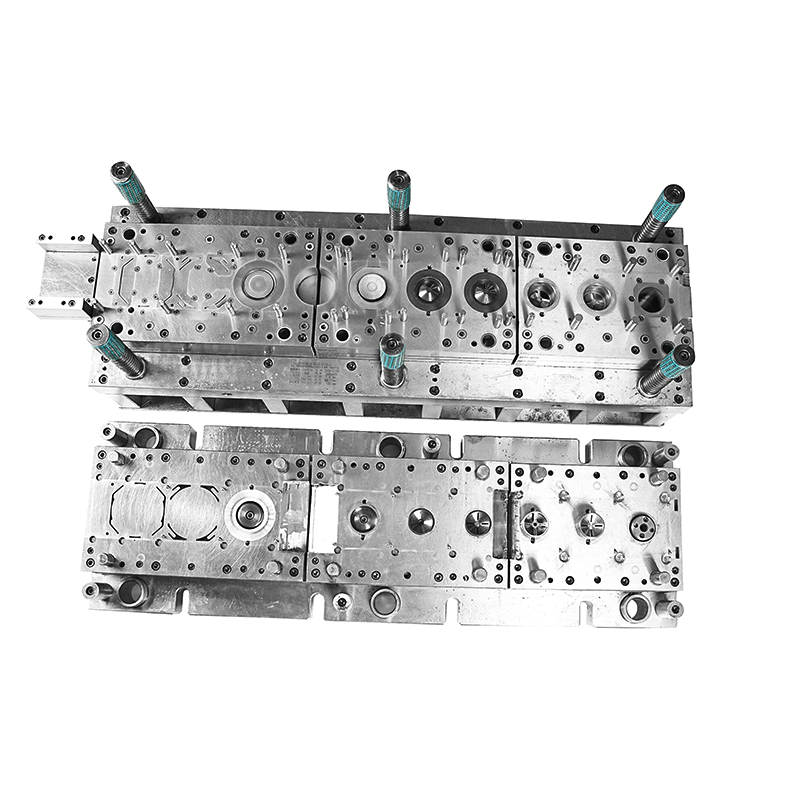

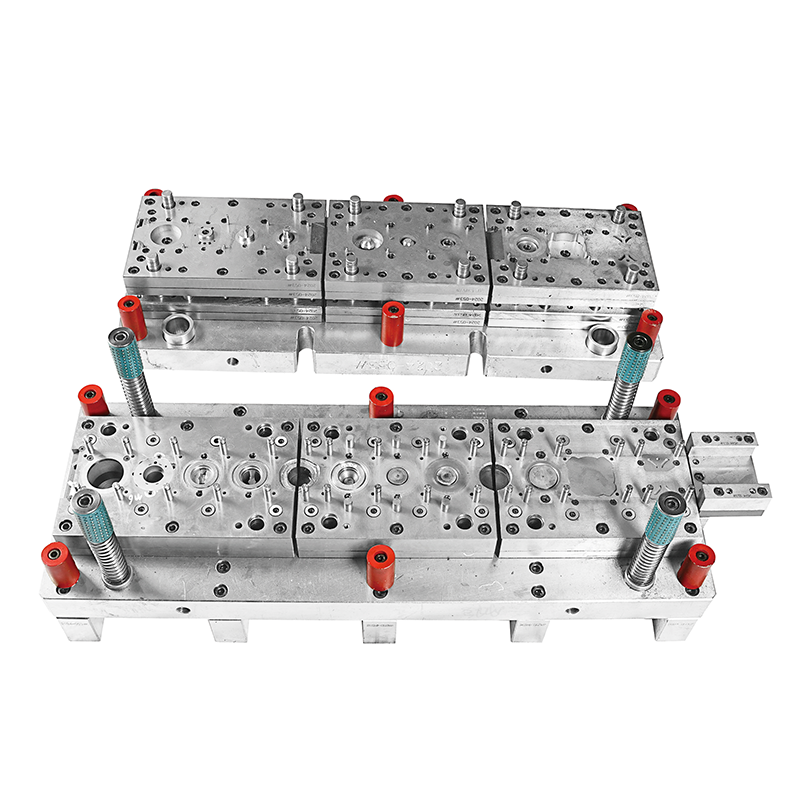

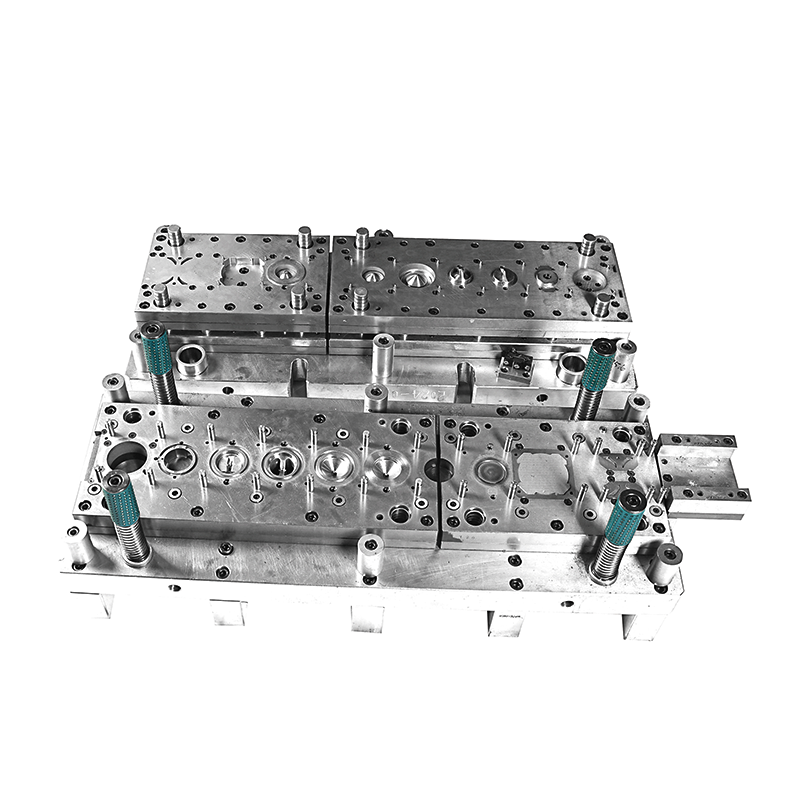

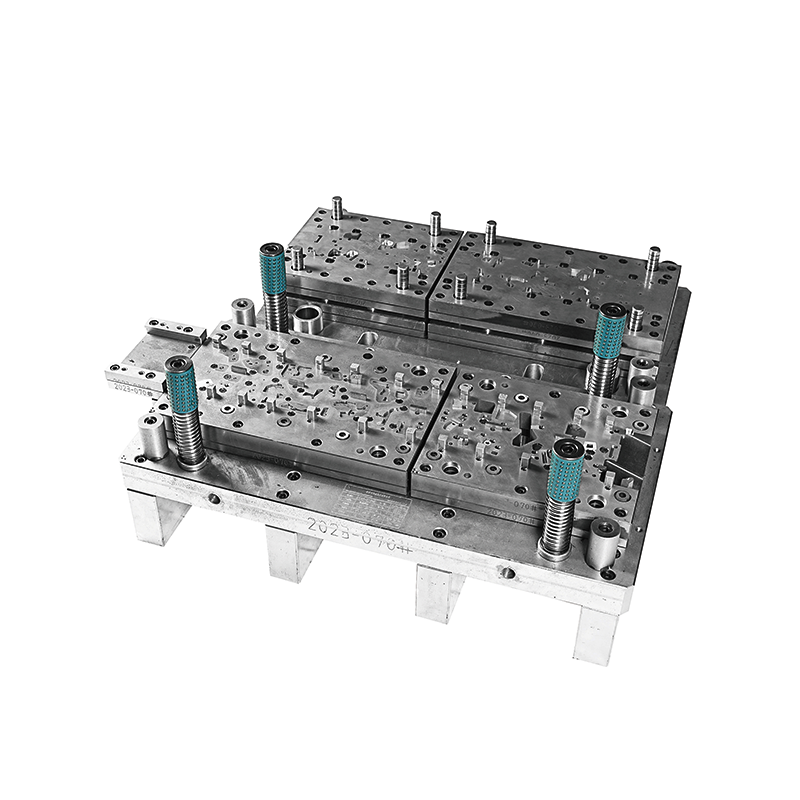

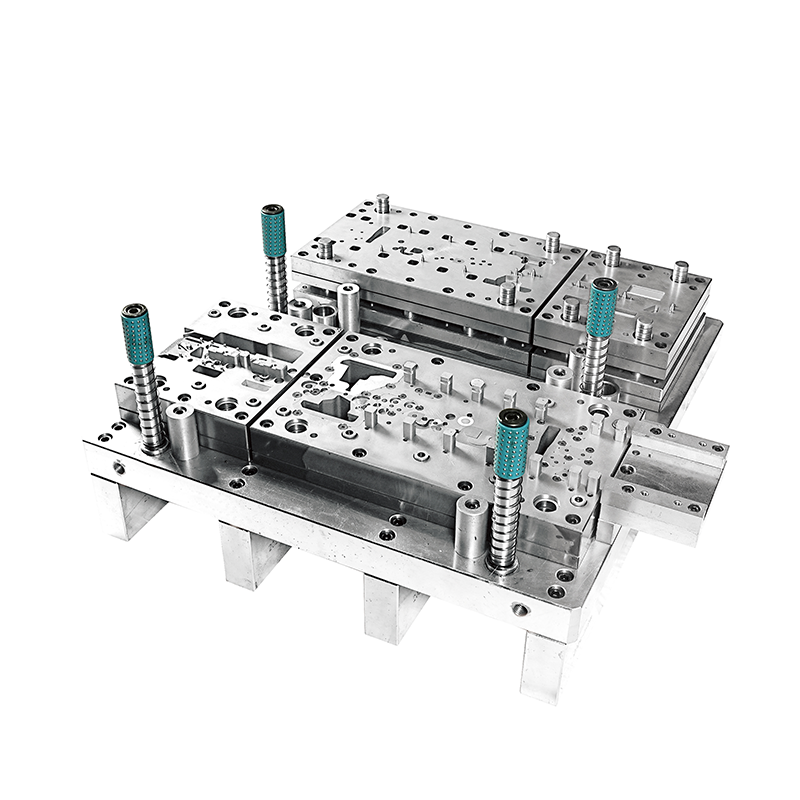

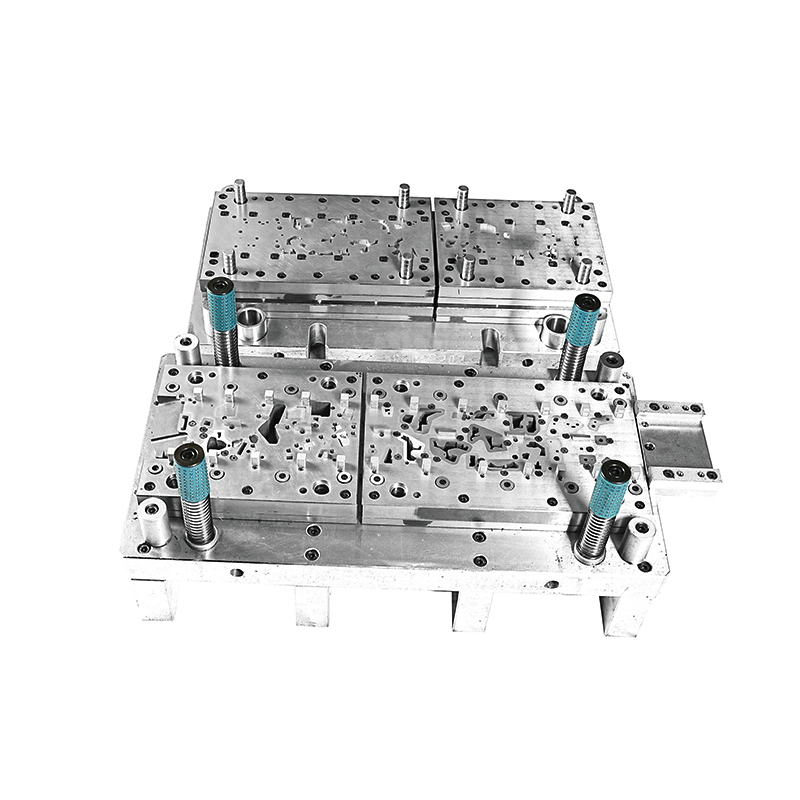

Mold design and manufacturing: According to the design drawings of the igniter stamping parts, the mold is designed using CAD/CAM technology, and then high-precision stamping molds are manufactured through precision machining equipment. The manufacturing accuracy of the mold directly determines the dimensional accuracy and quality of the stamping parts.

Stamping forming: The selected metal sheet or coil is placed in the stamping machine, and pressure is applied through the stamping die to cause the metal material to undergo plastic deformation to obtain the desired shape and size. The stamping process may include multiple processes such as blanking, bending, stretching, and punching to achieve the complex shape and structural requirements of the parts.

Surface treatment: In order to improve the performance and service life of the igniter stamping parts, they are usually surface treated. Common surface treatment processes include electroplating, nickel plating, chrome plating, etc. These treatments can improve the corrosion resistance, wear resistance and conductivity of the parts, while also improving their appearance quality. For some parts with special requirements, chemical plating, nitriding and other treatments may also be performed to further improve their performance.

Applications

The main types are: igniter housing, electrode assembly, etc., widely used in automobile and transportation, medical agriculture, industry and other fields

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: we are a mould company mainly engaged in the development, design, manufacturing and sales of moulds, such as automotive parts, motorcycle parts, hardware parts, electrical parts and other mould production and product stamping ect.

Q: What is surface treatment do you have?

A: Dacromet, powder coating, zinc plating, nickel plating, tin plating, copper plating, silver plating, gold plating, anodizing, salt spray test, etc. As we focus on stamping tools and metal stamping parts, the surface treatment is done through suppliers.

Q: Can I get samples?

A: Yes, sample order can be used for quality inspection and market testing, and freight will be collected. If it is a simple sample, we will not charge; if it is an OEM/ODM sample, we will charge sample fees.

Q: What is the minimum order quantity?

A: When there is stock, the minimum order quantity is 1000 pieces.

Q: When is the delivery time?

A: The stamping die manufacturing cycle is 20-50 days, and standard stamping parts can be delivered 3 to 10 days after payment. If it is OEM or making molds, we will confirm the delivery time with you.

Q: What are your payment terms?

A: We recommend a 50% T/T deposit and the balance paid before shipment.sample cost.

Q: Do you accept OEM/ODM?

A: Yes. We have more than 15 years of OEM/ODM experience.