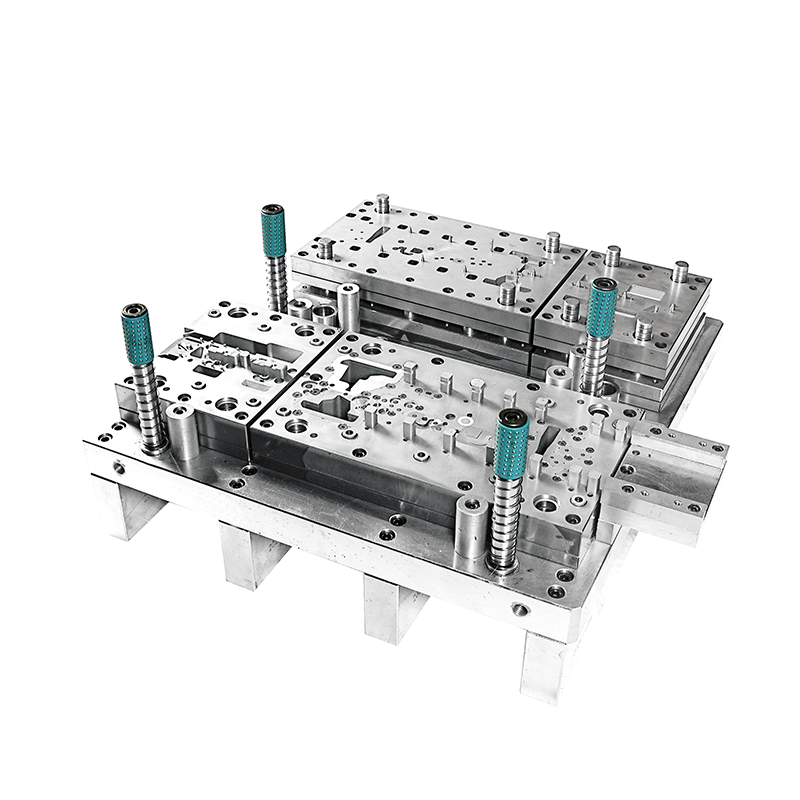

Cold Stamping Mold for Motorcycle and Bicycle Parts

As an informational note, the primary role of this cold stamping mold is the creation of components that are integral to the construction and operation of motorcycles and bicycles, for instance, chain guards, and brake levers, brake pads, and suspension plates. These parts are those that require not only high performance but also the most accurate measurements. The cold stamping process becomes the most eligible technology to carry out the shaping of the form of the metal parts, and it is applicable to such materials as medium- to high-strength steel, titanium, and aluminum, while the working temperature is still at the room one thus remaining their quite good mechanical properties; as a result, the purpose of one part has become multifunctional.

The radiant mold design can create a steel mold and coat it with wear-resistant materials making it an ideal candidate for a high tonnage press that it can run without stopping. We make a fully planned and automated progress or a single-step mold according to the requirement of the production.

The newly launched automated mold is characterized by the presence of ejector pins, guide posts, and is equipped with die inserts that are modular in nature designed for quicker changing. We can consider the adoption of the Finite Element Analysis method to simulate the behavior of the mold when it is producing the parts. Furthermore, the research concluded that the geometry of the models is not susceptible to being damaged or bent, thus it delivers consistent results consistently.

By choosing our stamping tools, rubber and bicycle OEMs are cutting short production line downtimes in their factories—production of higher-quality items is no longer just a dream but a reality. As soon as the second production run began, they became more efficient, and the significant reduction of the number reaches the previous time, dropping it to about 300ms on average, while the system is still able to produce products of the same quality.

Copyright © Pengjin Mold | Privacy policy