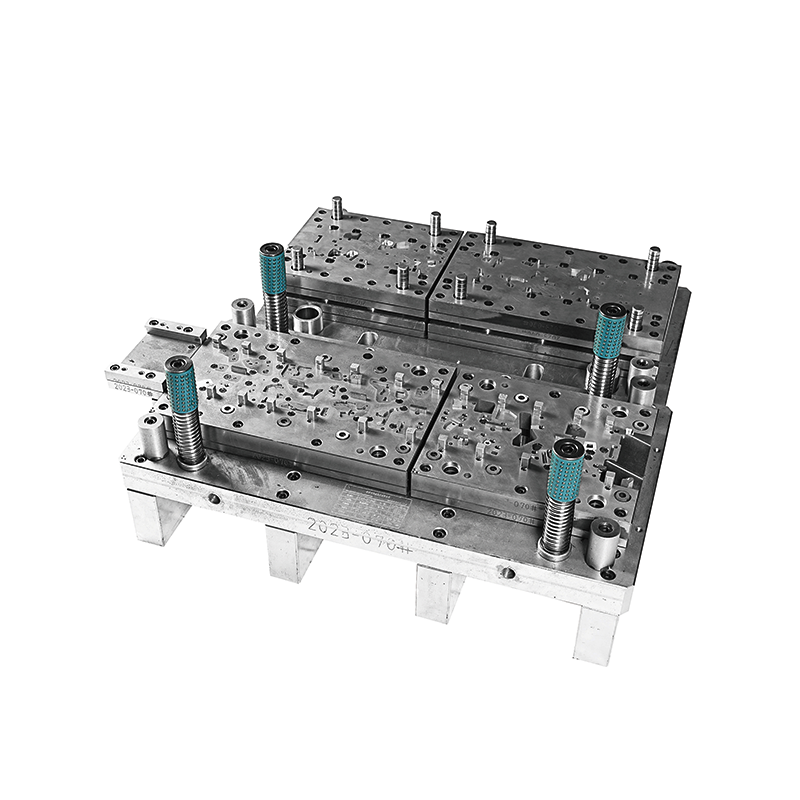

Progressive Mold for Medical Stainless Steel Instruments

The innovative mold, made specifically for surgical and diagnostic instruments of stainless steel, is a perfect fit for the most demanding hygiene requirements and allows the production of components with high accuracy. At every station, crucial operations like bending, piercing, notching, and deburring that have to be performed are made in an uninterruptedly progressive action. The mold, created by cold hardening H13 tool steel of high hardness level, is very robust. As it is quick and comes with hygienic mold plates that are easy to clean, it can be used in cleanroom or sterile production conditions, and it is equipped with quick-release plates for easy sterilization. By virtue of its narrow die clearance and the bright cleaned surface, it prohibited the bad things—that are, the medium from which the contamination spreads, and the adhesive surface causing the material to stick from happening. The tool is of a type which lends itself to be used for the pressing of parts, the example of components that can be given are the arms for forceps, locks for instruments, and the arms of knives, which means the medical OEMs have the advantage of achieving the highest possible productivity and the minimum amount of waste. It includes the ability to detect out-of-specification parts before they are fed down the line using sensors, which are an essential feature. The press that is used with the mold has a speed that is as high as 200 SPM and maintains the precise dimensions. The mold represents a high-frequency production tooling solution used to make precision parts made of stainless steel that are required in large quantities.

Copyright © Pengjin Mold | Privacy policy